- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

Customized

-

Size:

-

Customized

-

Power:

-

Customized

-

Weight (KG):

-

2000 kg

-

Product name:

-

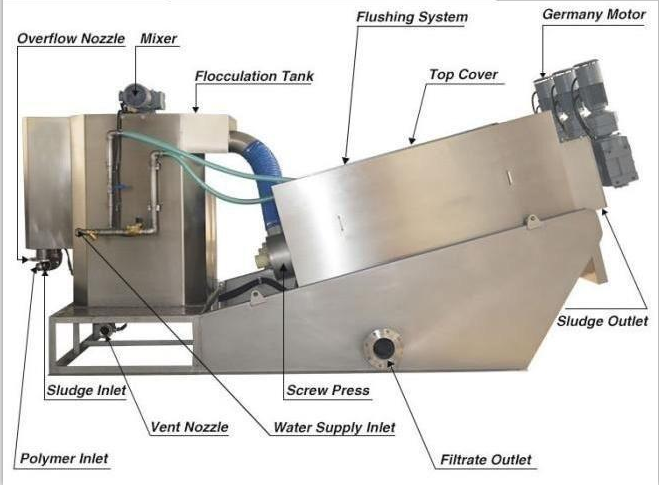

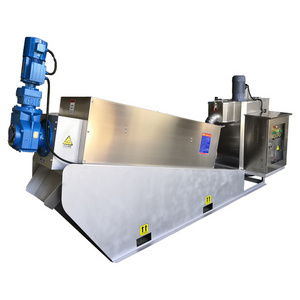

volute screw press sludge dewatering

-

Application:

-

sludge dewatering

-

Type:

-

Water Filter Parts

-

Usage:

-

Pure Water Process

-

Function:

-

Filtering Suspended Matter

-

Color:

-

As customers' request

-

Delivary:

-

Within 3 weeks after receiving the advance payment

-

Packing:

-

Standard Package

-

Payment:

-

As customers' request

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JIXU

-

Material:

-

Customized, Stainless Steel

-

Weight:

-

Customized

-

Size:

-

Customized

-

Power:

-

Customized

-

Weight (KG):

-

2000 kg

-

Product name:

-

volute screw press sludge dewatering

-

Application:

-

sludge dewatering

-

Type:

-

Water Filter Parts

-

Usage:

-

Pure Water Process

-

Function:

-

Filtering Suspended Matter

-

Color:

-

As customers' request

-

Delivary:

-

Within 3 weeks after receiving the advance payment

-

Packing:

-

Standard Package

-

Payment:

-

As customers' request

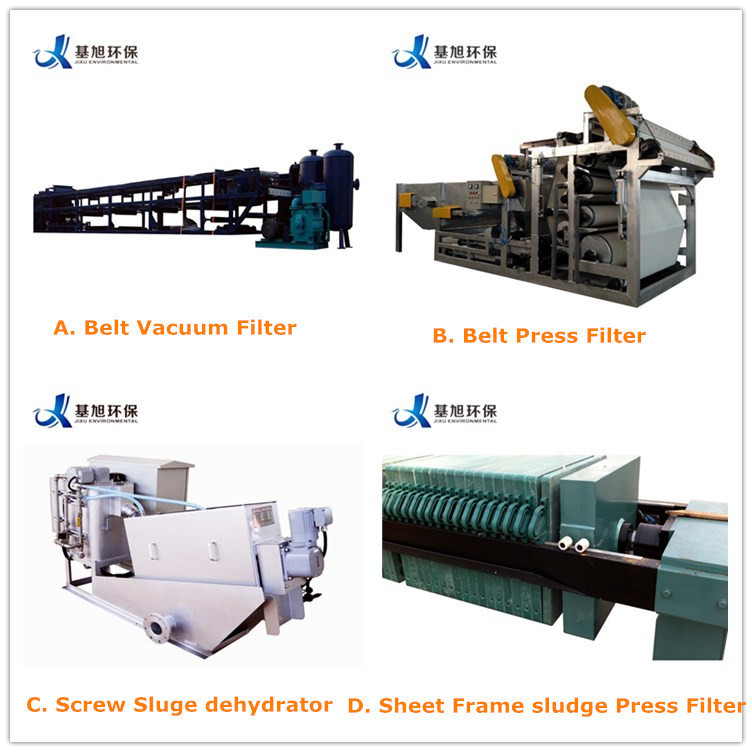

Series:

a.Belt Filter Press

b.Belt Vavuum Filter

c.Sheet frame sludge press filter

d.Spiral Sewage Thickener

You can send inquiry or email us directly to sales(at)pro-equipments.com.

And tell us your demands or which kinds of machine is you need,the more details of this machine will be sent you quickly.

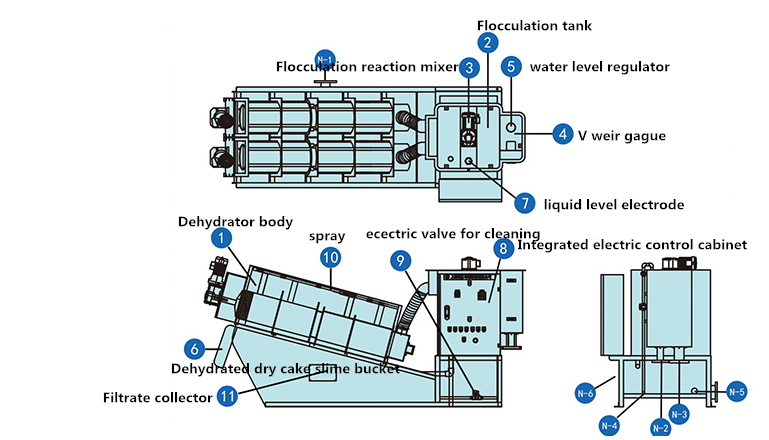

1. Concentration: When the screw pushes the shaft to rotate, the multiple solid laminations disposed on the periphery of the push shaft move relative to each other. Under the action of gravity, water is filtered out from the relatively moving lamination gap to achieve rapid concentration

2. Dehydration: The concentrated sludge moves forward with the rotation of the screw shaft; along the exit direction of the mud cake, the pitch of the screw shaft gradually becomes smaller, and the gap between the ring and the ring gradually becomes smaller, and the volume of the spiral cavity becomes smaller. Continuous shrinkage; under the action of the back pressure plate at the outlet, the internal pressure is gradually enhanced. Under the continuous driving of the spiral push shaft, the water in the sludge is squeezed out, and the solid content of the filter cake is continuously increased, and finally the sludge is realized. Continuous dehydration.

3. Self-cleaning: The rotation of the screw shaft pushes the swimming ring to rotate continuously. The device relies on the movement between the fixed ring and the swimming ring to realize a continuous self-cleaning process, thereby cleverly avoiding the clogging problem common to the traditional dewatering machine.

1. Suitable for sludge in municipal sewage, food, beverage, chemical, leather, welding consumables, papermaking, printing and dyeing, pharmaceutical and other industries.

2. Suitable for dewatering of high and low concentration sludge. When dewatering low concentration (2000mg/L~) sludge, it is not necessary to build a concentration tank or a storage tank, reduce construction cost, reduce phosphorus release and anaerobic odor generation.

PACKAGE:

As customers' request or export seaworthy package

DELIVERY TIME:

20 days after

receiving deposit

,detail delivery date should be decided according to

order quantity.