- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

15KW-65KW

-

Dimension(L*W*H):

-

According to customization

-

Weight (KG):

-

5000

-

Product name:

-

Alfalfa Hay Grass Mesh Belt Dryer Cassava Chips Hot Air Drying Machine

-

Product Type:

-

Mesh Belt Dryer

-

Drying method:

-

Heated air circulation

-

Status:

-

Fully automatic with continuous working

-

Uniformity:

-

Above 98%

-

opeating temperature:

-

40-120℃, adjustable

-

Machine material:

-

SUS304, SUS316, Stainless steel

-

WhatsApp:

-

+86 13598071775

-

Discount:

-

5% or more

Quick Details

-

Type:

-

Belt Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HKB

-

Voltage:

-

220V/380V

-

Power:

-

15KW-65KW

-

Dimension(L*W*H):

-

According to customization

-

Weight (KG):

-

5000

-

Product name:

-

Alfalfa Hay Grass Mesh Belt Dryer Cassava Chips Hot Air Drying Machine

-

Product Type:

-

Mesh Belt Dryer

-

Drying method:

-

Heated air circulation

-

Status:

-

Fully automatic with continuous working

-

Uniformity:

-

Above 98%

-

opeating temperature:

-

40-120℃, adjustable

-

Machine material:

-

SUS304, SUS316, Stainless steel

-

WhatsApp:

-

+86 13598071775

-

Discount:

-

5% or more

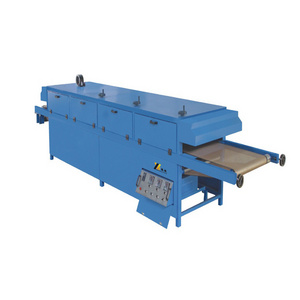

Alfalfa Hay Grass Mesh Belt Dryer Cassava Chips Hot Air Tunnel Oven Drying Machine

| Product Description |

Mesh belt dryer is a batch type, continuously working drying equipment. Mesh belt dryer is usually used to dry cassava chips, fruits, vegetables, food, etc. Mesh belt dryer has features with high efficiency, high capacity, high evaporation strength, standardized production. We could increase the segment according to the capacity. Mesh belt dryer has a high efficiency for the materials that request low moisture content. We could supply customization service according to the client request. The main heating mode is electric heating, steam heating, hot air heating, Materials that are processed by mesh belt dryer are easy to store and transport. Mesh belt dryer is energy-saving and environment-protecting equipment that creates a good economic benefit and social benefit.

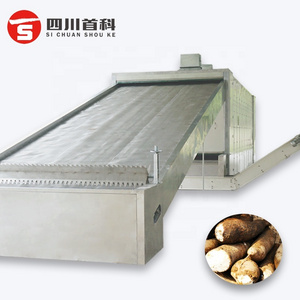

| Application |

Mesh belt dryer is mainly used for continuous drying of materials with large capacity. It can dry most materials such as vegetables, grains, fruits, flowers and leaves, pastures, etc. It has been applied to the drying of more than 300 materials, realizing multiple functions in one machine, and bringing huge economic benefits to our customers.

| Feature |

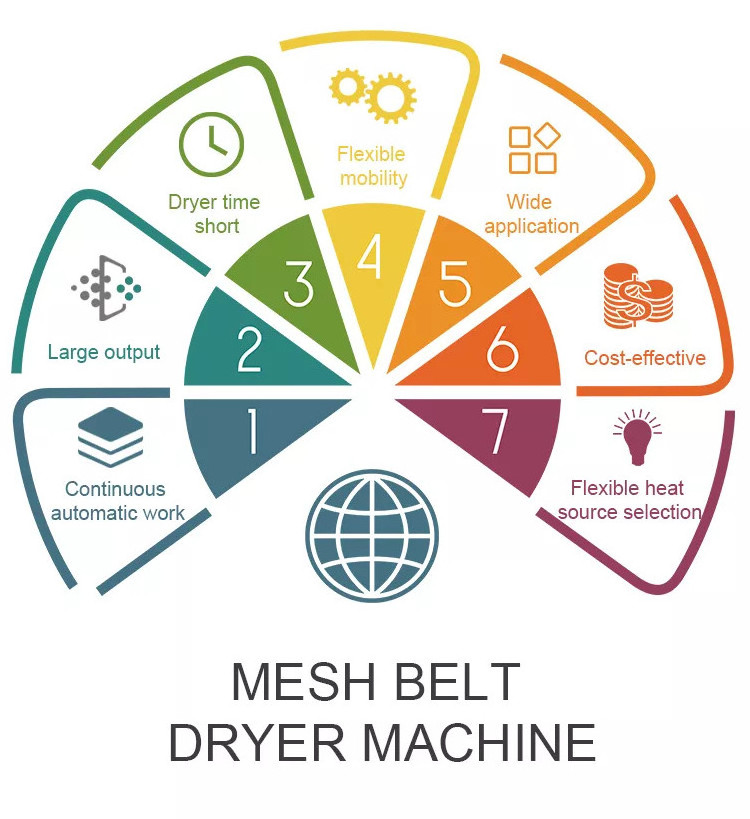

1. Wide applications: The residence/drying time is adjustable from 15 minutes to 120minutes which makes it flexible to dry various kinds of raw material.

2. Energy-saving: Different types of hot air flow pattern and well insulated drying chamber can considerably reduce heat loss. Hot air circulation can be designed for energy-saving.

3. Uniform drying: The specially designed hot air distributor and drying zones can make sure uniform air flow in side the whole drying chamber to guarantee uniform drying.

4. Easy operation and maintenance: The whole drying system is highly automatic. The simple but practical design can not only reduce production cost but also maintenance and repair cost.

5. Flexible heat source: The heat source for drying can steam, electricity, hot water, thermal oil or oil/gas/coal/biomass fired hot air generator. We can design and engineer different heat source according to customer's actual conditions.

6. Different types and layers of mesh belt are vailable based on specific raw material and drying conditions.

| Technical Parameter |

| Model | DW2*6-6 | DW2*6-8 | DW2*6-10 | DW2*6-12 |

| Length(mm) | 6000 | 8000 | 10000 | 11800 |

| Weight(mm) | 2100 | 2100 | 2100 | 2100 |

| Height(mm) | 2400 | 2400 | 2400 | 2400 |

| Drying layer | 4 | 4 | 4 | 4 |

| Drying Area(m2) | 43 | 57 | 72 | 86 |

| Feeding Conveyor Size(L*W) | 4000*1800 | 4000*1800 | 5000*1800 | 6000*1800 |

| Feeding Conveyor and Dryer Power(KW) | 3 | 3 | 3 | 4 |

| Outlet Conveying Size(L*W) | 5000*300 | 5000*300 | 5000*300 | 5000*300 |

| Discharge Conveying Power(KW) | 0.14 | 0.14 | 0.14 | 0.14 |

The above data is for reference only. For more information, please contact us.

| Working Principle |

Mesh belt type drying machine main principle is the material evenly tiled on the mesh belt, is driven by the drive device in the dryer moving back and forth, hot air in materials and the cross flow, water vapour from the wet discharging hole in discharge, so as to achieve the purpose of drying. Network with 12-60 to wire mesh belt, the body length by a combination of the standard section, in order to save space, the drying mechanism into multi-layer, common has two room three and two-room five layers, length 6-40m, effective width 0.6-3.0m.

The material has the nose to enter slowly through the drying for drying, net belt line speed depending on the type of material and water content. Air flow to the use of negative pressure, porous air, to ensure the effective drying area, wind speed distribution uniformity, improve the drying effect. In order to get the best drying effect and the appropriate output, the water content of the material, the line speed of the net belt, the air volume and the air temperature must be the appropriate, reasonable and organic combination.

| Details |

| Packaging&Delivery |

| Related Products |

| Mesh Belt Dryer | Sawdust Rotary Dryer | 100-10000 Ton Silo | Vertical Grain Dryer |

| Company Introduction |

Henan Haokebang Machinery Equipment Co., Ltd. is located in Henan Province, China, covering an area of 32,000 square meters and having a standardized heavy-duty industrial plant of 15,000 square meters. The company specializes in the production of grain dryers, silos, tubular dryers, mesh belt dryers, grain cleaning screens and other grain processing equipment.

The company is well-equipped with more than 20 large and medium-sized machining, riveting, and assembly equipment, including fully automatic bending machines, laser cutting machines and other modern production equipment. Our company has more than 100 management personnel and engineering and technical personnel with intermediate and senior professional titles. It is a modern enterprise integrating R&D, production, sales and maintenance.