- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

13kw

-

Dimension(L*W*H):

-

2500*1300*1900mm

-

Weight:

-

1500 kg

-

Certification:

-

ce

-

After-sales Service Provided:

-

Online support

-

Speed:

-

70-90pcs/min

-

Function:

-

paper cup

-

Automation:

-

Fully Automation

-

Paper Cup Size:

-

2-9oz

-

Working Air Source:

-

0.2cbm/min

Quick Details

-

Production Capacity:

-

80 pcs/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

GOOD

-

Voltage:

-

380v

-

Power:

-

13kw

-

Dimension(L*W*H):

-

2500*1300*1900mm

-

Weight:

-

1500 kg

-

Certification:

-

ce

-

After-sales Service Provided:

-

Online support

-

Speed:

-

70-90pcs/min

-

Function:

-

paper cup

-

Automation:

-

Fully Automation

-

Paper Cup Size:

-

2-9oz

-

Working Air Source:

-

0.2cbm/min

Products Description

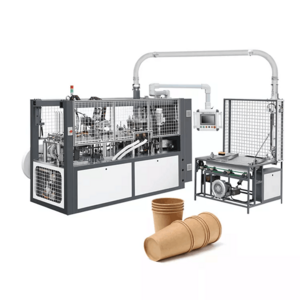

MB-D12 medium speed paper cup machine use 2 turning plates to finish the whole cup forming

procedure,and perfectly upgraded and replaced the old 3 turning plates plated paper cup machines,which greatly simplified the paper cup producing steps, and increase the productivity.

procedure,and perfectly upgraded and replaced the old 3 turning plates plated paper cup machines,which greatly simplified the paper cup producing steps, and increase the productivity.

whats more,

40ft container can load 12sets MB-D12 machine,it can save your sea freight

|

Technical Specification:

|

|

|

size

|

2-9oz

|

|

material

|

170-230gsm single pe and double pe coated paper

|

|

speed

|

70-90pcs/min

|

|

power

|

380v/220v 5kw

|

|

air source

|

0.2cbm/min

|

|

weight

|

1500kgs

|

Machine details:

1. Paper cup bottom sealing by heater.

2. Cup side sealing by heater or ultrasonic as per your requirements.

3. Withour unique original designed bottom knurling system, single shaft, Korea type, this ensures the low leaking ratio and high

quality of paper cups.

4. With unique Open Cam design,it would be more stable when machine running at a high speed.

5. With automatic lubricating system, it will automatic lubricating to every moving parts when machine runs.

6. Every cam will be harden to ensure it can run for a long long time.

7. Machine is designed with double turning plate

8. Bottom paper we have a special control system, if connect with air source, bottom would be in pace with the cup body, so its more efficient and “0” waste on bottom paper

2. Cup side sealing by heater or ultrasonic as per your requirements.

3. Withour unique original designed bottom knurling system, single shaft, Korea type, this ensures the low leaking ratio and high

quality of paper cups.

4. With unique Open Cam design,it would be more stable when machine running at a high speed.

5. With automatic lubricating system, it will automatic lubricating to every moving parts when machine runs.

6. Every cam will be harden to ensure it can run for a long long time.

7. Machine is designed with double turning plate

8. Bottom paper we have a special control system, if connect with air source, bottom would be in pace with the cup body, so its more efficient and “0” waste on bottom paper

A list of sample

Recommend Products

Certifications

Exhibition

Hot Searches