- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YunJin

-

Voltage:

-

220v

-

Power:

-

1.1kw

-

Dimension(L*W*H):

-

1450*710*1700mm

-

Weight:

-

180 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

baozi Dimsum Machine Nepal Steamed Stuffed Bun Momo Making Machine

-

Material:

-

Stainless Steel, Easy To Operate Stuffed Bun Making Machine

-

Usage:

-

Cooking Equipment

-

Packaging Details:

-

Wooden case, steamed pork bun dumpling momo maker making machine

-

Feature:

-

High Efficiency

-

MOQ:

-

1 Set, Easy To Operate Stuffed Bun Making Machine

Quick Details

-

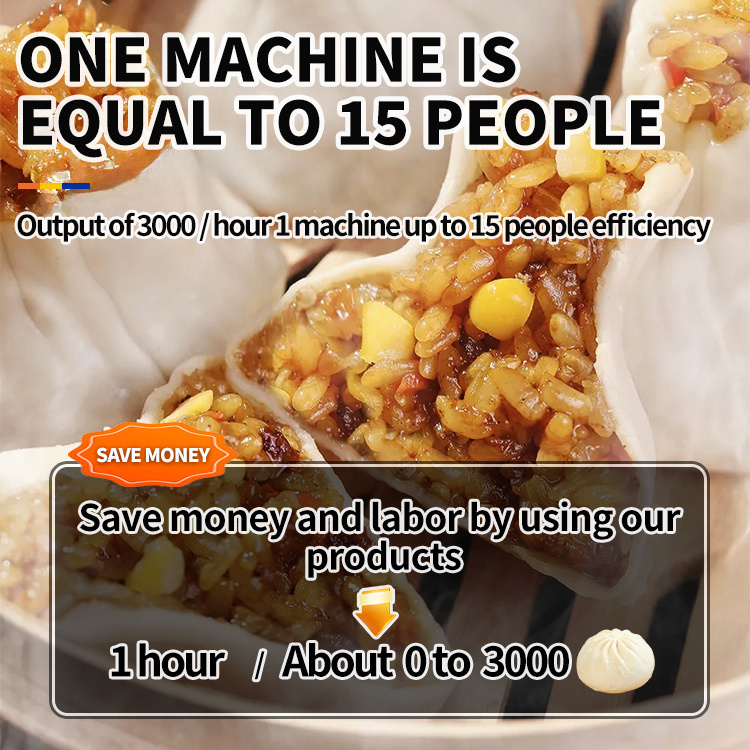

Production Capacity:

-

3000 pieces/h

-

Type:

-

steamed stuffed bun

-

Place of Origin:

-

Henan, China, Henan, China, Easy To Operate Stuffed Bun Making Machine

-

Brand Name:

-

YunJin

-

Voltage:

-

220v

-

Power:

-

1.1kw

-

Dimension(L*W*H):

-

1450*710*1700mm

-

Weight:

-

180 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

baozi Dimsum Machine Nepal Steamed Stuffed Bun Momo Making Machine

-

Material:

-

Stainless Steel, Easy To Operate Stuffed Bun Making Machine

-

Usage:

-

Cooking Equipment

-

Packaging Details:

-

Wooden case, steamed pork bun dumpling momo maker making machine

-

Feature:

-

High Efficiency

-

MOQ:

-

1 Set, Easy To Operate Stuffed Bun Making Machine

Products Description

|

Steamed bun machine

|

|

|

|

|

|

|||||

|

Model

|

Capacity (pieces)

|

Voltage(v)

|

Power(kw)

|

Weight(kg)

|

Size(mm)

|

|||||

|

YJ-BZJ

|

0-3000

|

220

|

1.1

|

180

|

1450*710*1700

|

|||||

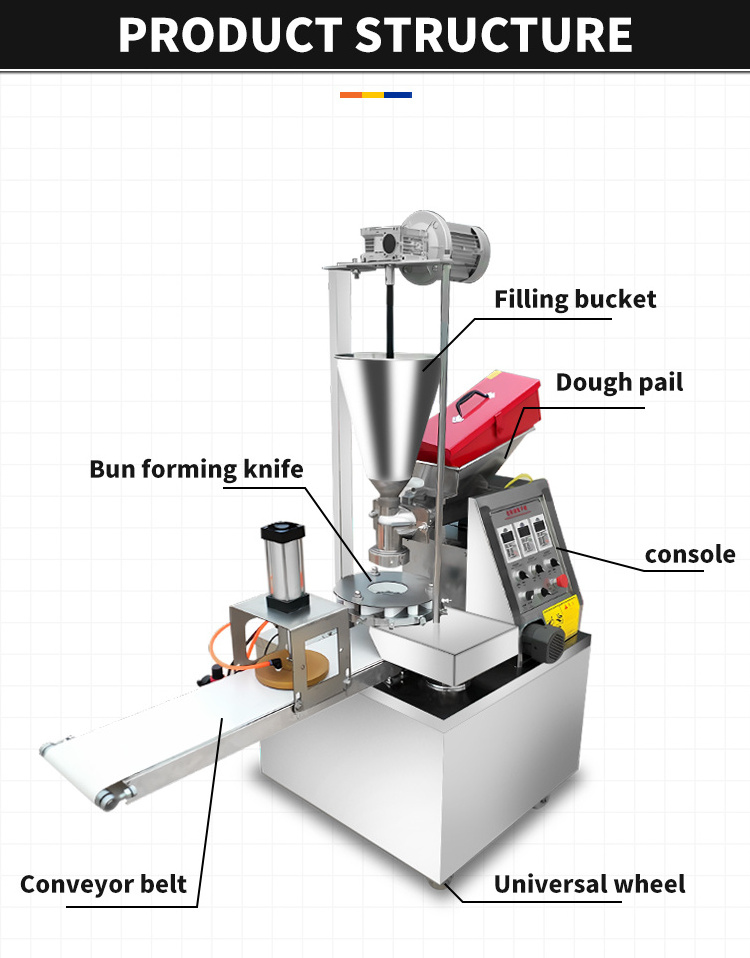

Steamed bun machine:

The steamed bun machine is a food machine that puts the fermented dough and mixed fillings into the machine to process the steamed buns.

Product Details

Working principle:

During the working process, the filling supply hopper transports the filling to the filling supply regulating pump, and the dough supply hopper transports the dough to the extrusion noodle making tube. A filling noodle column is formed at the outlet of the machine head, and then the dough is formed by the forming block in the forming plate. Squeeze the noodles into evenly sized buns.

Product Features

Product advantages:

1. The

improved head of the automatic bun machine

has dual frequency conversion for imported products and more stable performance.

2. The advanced dough feeding and filling system of the multifunctional bun machine fully protects the chewy texture of the dough, truly does not damage the dough, and ensures the texture of the buns. The filling is fed smoothly and evenly, and the buns can be formed with excellent results no matter what kind of fillings are used.

2. The advanced dough feeding and filling system of the multifunctional bun machine fully protects the chewy texture of the dough, truly does not damage the dough, and ensures the texture of the buns. The filling is fed smoothly and evenly, and the buns can be formed with excellent results no matter what kind of fillings are used.

3. The bun machine is scientifically designed according to the pastry process requirements to ensure product density, uniform and delicate pores, excellent elasticity, toughness, and water holding capacity. The product surface is bright and delicate, the pattern is neat, and the taste is smooth,

far exceeding that of hand-made products.

4. The bun machine

adopts a humanized control panel and high-quality microcomputer control

. The control is accurate and reliable, and can be operated freely in 5 minutes.

5. High degree of automation, accurate quantification, consistent product size, skin-to-stuffing ratio of 20g-150g, adjustable at will, and can be operated by 1-2 people.

6. The bun machine has diversified products and can produce various stuffed products such as buns, pumpkin cakes, xiaolongbao, mung bean cakes, and bean paste buns.

6. The bun machine has diversified products and can produce various stuffed products such as buns, pumpkin cakes, xiaolongbao, mung bean cakes, and bean paste buns.

7. The machine is lightweight and

its main parts are made of stainless steel

. It has a beautiful appearance and complies with national food hygiene standards.

8. The bun machine has

a reasonable structure

. The forming, filling, dough feeding and control panels are all driven by independent motors, making it less prone to associated failures and easy to maintain and clean.

9. The bun making machine

does not have high requirements on flour quality

, occupies a small area, is easy to move, and is suitable for various workplaces.

10. The working efficiency of the bun machine is equivalent to 8 to 12 workers making buns by hand at the same time. It is truly low investment,

high efficiency and investment saving

.

Product Application

Precautions:

1. The machine should be cleaned in time after each use, because things that come into contact with food must be kept clean.

2. When disassembling and assembling the noodle and filling mechanism and blades, it is strictly forbidden to use hard objects to smash, beat, pry and other bad operations.

3. Clean the blade and put it back. Please pay attention to the placement.

4. Add a little cooking oil or grease between the blades before starting the machine, and also inject an appropriate amount of cooking oil into the transmission parts.

5. Apply vegetable grease to the cam groove once per shift.

6. Each bearing should be disassembled and cleaned every six months.

7. Please follow the routine maintenance of mechanical and electrical products for the reduction motor.

Hot Searches