- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HST

-

Model Number:

-

WDW-10KN

-

Weight group:

-

100N,200N,300N,500N,1000N

-

Measurement range:

-

100N-10kN

-

Force accuracy:

-

0.005%

-

Adding and unloading time:

-

less than 10s

-

Test space:

-

no less than 200mm wide, pull/pressure two-way height: 400mm

-

Brand:

-

HST

-

Certification:

-

CE, ISO

Quick Details

-

Warranty:

-

1year

-

Power:

-

Electronic

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HST

-

Model Number:

-

WDW-10KN

-

Weight group:

-

100N,200N,300N,500N,1000N

-

Measurement range:

-

100N-10kN

-

Force accuracy:

-

0.005%

-

Adding and unloading time:

-

less than 10s

-

Test space:

-

no less than 200mm wide, pull/pressure two-way height: 400mm

-

Brand:

-

HST

-

Certification:

-

CE, ISO

Force Value Calibration Standard Load Testing Machine

Product Description

1. Introduction

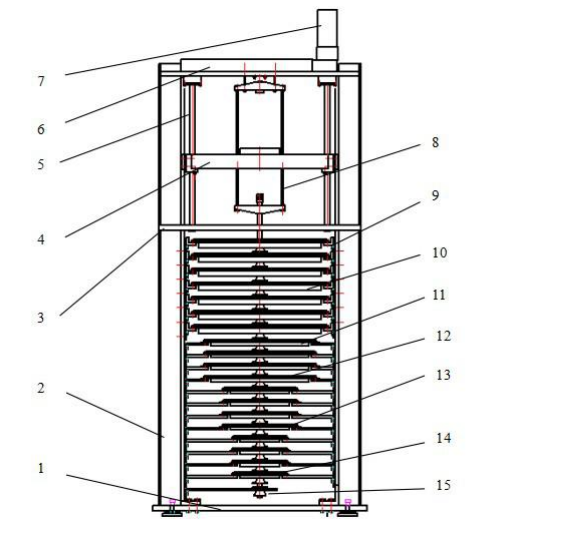

The LBJ Series standard load testing machine is a measuring instrument for force value calibration, which

can be used for tensile and compression tests.It is mainly composed of main machine, table type electric

control cabinet and computer system.

1,the bottom plate 2, the column 3, the workbench 4, the moving beam 5, the lead screw 6, the upper beam 7,

the gear motor 8. Reaction force frame 9. Cam mechanism 10, 1000N weight components 11, 500N weight

components 12, 200N weight components 13, 100N weight components 14, anti-swing components

2.2 Weight and its drive mechanism

There are 19 independent weights, and the hanging component can be counted as a weight with a total

mass of 10100N. It can apply a load of no more than 1000N and a minimum rating of 100N.

The loading or unloading of the weight is determined by the pallet lifting of the weight, and the lifting of the

weight pallet is determined by the highest and lowest points of the cam. The cam mechanism is realized by the

rotation of the micro motor. Therefore, the micro-motor is used to make the weight tray move up and down

linearly by the cam mechanism, and the downward movement is performed to complete the loading and

unloading of the weight, and the upward movement is performed to complete the unloading of the weight. Each

weight is driven by a synchronous micromotor drive mechanism, together with the tray slider, guided by a linear

guide, by loading up and down linear motion (applying to the bracket of the boom), or unloading (from the

suspension of the boom) Remove from the block).The loading or unloading process of the weight is completely

completed by the proximity switch to the microcomputer control system.

3. Control System

Adopt Japanese Panasonic PLC control system, computer operation method, automatic loading and unloading.

Automatically collect data, store, and automatically print test reports. With security protection {emergency stop}

China i

button switch.

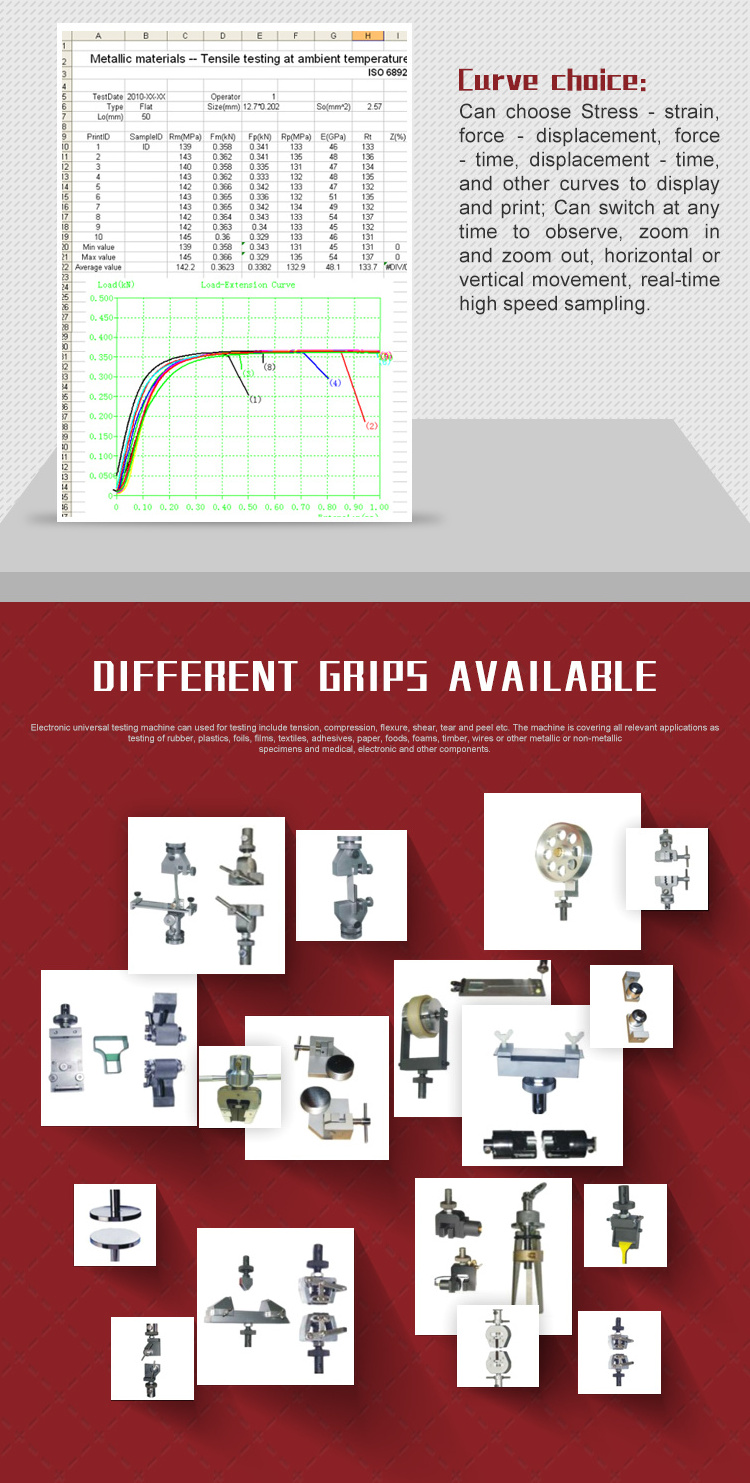

4. Operating software

The software system is designed and developed by the our company. It has real-time monitoring of running

status, real-time display of the number and position of weight loading, etc. It has real-time pause, one-key

recovery, automatic unloading and other functions.

Hot Searches