- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Xicheng

-

Dimension(L*W*H):

-

custom made

-

Weight:

-

100

-

Application:

-

CHEMICAL STORAGE

-

Material:

-

PP

-

Color:

-

Beige/grey

-

MOQ:

-

1 Unit

-

Keywords:

-

Gasoline Storage Tank

-

Features:

-

Anti-Corrosion

Quick Details

-

Capacity:

-

Customized

-

Max Working Pressure(MPa):

-

1000 MPa

-

Core Components:

-

pp

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Xicheng

-

Dimension(L*W*H):

-

custom made

-

Weight:

-

100

-

Application:

-

CHEMICAL STORAGE

-

Material:

-

PP

-

Color:

-

Beige/grey

-

MOQ:

-

1 Unit

-

Keywords:

-

Gasoline Storage Tank

-

Features:

-

Anti-Corrosion

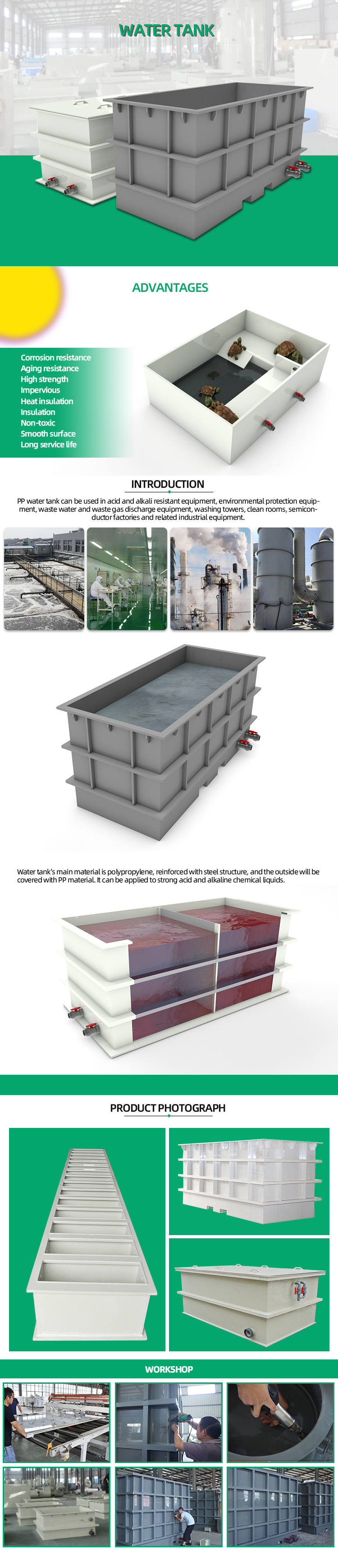

Features

Electroplating baths are the most common sink and pickling tank in electroplating equipment. The material is made of PP material and steel structure material. Electroplating tanks can be used to install solutions for galvanizing, copper plating, nickel plating, gold plating and the like. The cathode moving plating tank is composed of tank body, conductive device, steam heating tube and cathode moving device of steel groove lining soft PVC plastic. The choice of the tank structure depends on the nature of the bath and the temperature and other factors. It consists of tank body, solution heating and cooling device, conductive device, motor, reducer, eccentric disk, connecting rod and pole support roller.

The optimum size of the plating bath is of great importance to the growth plan, the estimation of the yield and the quality of the plating. To determine the size of the plating tank need to meet the three conditions:

1.to meet the processing requirements of the parts, to fully submerged parts to be electroplated all the surface;

2. to maintain the plating cycle of electrolyte content of certain stability.

3.but also take into account the overall coordination of the production line to meet the rationality of electroplating workshop layout requirements.

-

PERSONALIZED CUSTOMIZATION

The products can be customized according to customers' requirments and drawings.

-

INSTALLATION

Our company can send professional engineers to guide device installation and provide a professional plan.

-

AFTER SERVICE

Our equipment will have a one-year life of quality assurance, repair and replacement are guranteed.