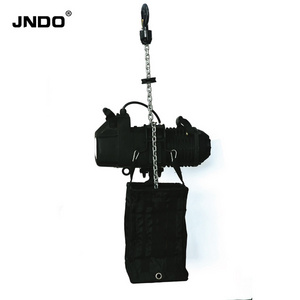

Downside hung electric hoists are generally used for touring performance concert. For its small size and easy for shipping.

Upside hung electric hoists are often used for permanent establishment,for example: large meeting hall, theatre, banquet, etc. It is more stable with higher safety factor.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KRC

-

Lift Speed:

-

0-30m/min

-

Marketing Type:

-

Hot Product 2024

-

Weight (KG):

-

70 kg

-

Product name:

-

Stage electric chain hoist

-

Maximum Lifting Height:

-

Customized

-

level of Protection:

-

IP66

-

Capacity:

-

Customized

-

After Warranty Service:

-

Field maintenance and repair service

-

Certification:

-

CE ISO

-

MOQ:

-

1 Set

Quick Details

-

Warranty:

-

1 years, 1 Year

-

Applicable Industries:

-

Entertainment industry, Party stage

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KRC

-

Lift Speed:

-

0-30m/min

-

Marketing Type:

-

Hot Product 2024

-

Weight (KG):

-

70 kg

-

Product name:

-

Stage electric chain hoist

-

Maximum Lifting Height:

-

Customized

-

level of Protection:

-

IP66

-

Capacity:

-

Customized

-

After Warranty Service:

-

Field maintenance and repair service

-

Certification:

-

CE ISO

-

MOQ:

-

1 Set

Waterproof Performance Test

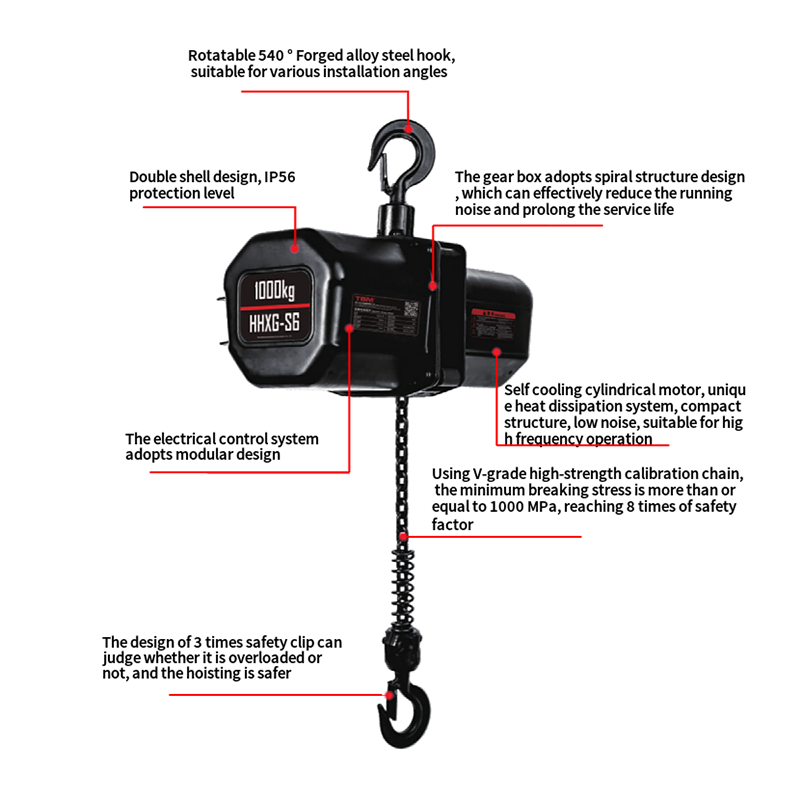

Stage Hoist Overview

Features of Su-type Stage Hoist

SU STAGE ELECTRIC HOIST

1. IP66 grade protection

2.

Helical gear multi-drive transmission

3.

Imported wet clutch friction pad. Overload protection,anti-collision. Maintence free.

4.

Electromagnetic brake

5.

High performance electric motor

6.

G100 grade load chains

7.

Compliance to German standard BGV-D8 regulation,CE certified.(

OPTIONAL ENCODER TO REALIZE DIGITAL CONTROL.)

SU-G+ UPSIDE HUNG STAGE ELECTRIC HOIST

1.

Aluminum shell

2.

Double electromagnetic brakes

3. High performance electric motor with overheat protection device

4. G100 chains made of alloy steel ,8 times safety factor, compliance to EN818-7.

5. Touch type limit switch

6. Overload clutch

7. Gear transmission set

3. High performance electric motor with overheat protection device

4. G100 chains made of alloy steel ,8 times safety factor, compliance to EN818-7.

5. Touch type limit switch

6. Overload clutch

7. Gear transmission set

8.

Lifting sprocket

9.

Compliancec to germany BGG-D8+ regulation. CE certified.(

OPTIONAL ENCODER TO REALIZE DIGITAL CONTROL.

)

SU-GP+ STAGE ELECTRIC HOIST

1. Aluminum shell

2.

Maintainence free double electromagnetic disc brakes

3. Chains with 10 times safety factor

4. Non-synchronous operation and all centralized stop.

5. Synchronous grouping drive,adjustable lifting speed

6. Payload retaining

7. Ultra-quiet brakes

8. Optional for 4 points limit switch

3. Chains with 10 times safety factor

4. Non-synchronous operation and all centralized stop.

5. Synchronous grouping drive,adjustable lifting speed

6. Payload retaining

7. Ultra-quiet brakes

8. Optional for 4 points limit switch

SU-GP+(C1) STAGE ELECTRIC HOIST

1.

Full sealed shell,high sealing performance.No sharp edges or bumps.

2.

Chains with 10 times safety factor

3. Double independent brakes system with independent controls

4. 2 hooks or rings are served.

5. Overload and underload monitor

6. Non synchronous or synchronous grouping operation,

adjustable lifting speed

7. 4 points position limit feedback,electromagnetic brake on/off feedback and double encoders positioning feedback

8. Ultra-quiet brakes

3. Double independent brakes system with independent controls

4. 2 hooks or rings are served.

5. Overload and underload monitor

6. Non synchronous or synchronous grouping operation,

adjustable lifting speed

7. 4 points position limit feedback,electromagnetic brake on/off feedback and double encoders positioning feedback

8. Ultra-quiet brakes

9.

Participated in many large scale outdoor performances,

stadiums and other CNC hoisting projects

stadiums and other CNC hoisting projects

About the Controller Customization

Wired Load Monitoring Control System

1.The wired load monitoring and control system can achieve multi line connection, supporting 4, 8, 12, 24 channels, etc. It can be extended up to 250 channels through relay, achieving group control operation and improving work efficiency.

2.The outer shell design of the aviation box is corrosion-resistant and meets the needs of the mobile performance market, making it easy to carry and transport.

3.Multiple control gears for more comprehensive functionality and convenient use, equipped with emergency stop buttons for quick handling in emergency situations.

4.High quality aviation plugs are designed with grounding pins and insulation materials to effectively prevent current leakage and short circuits, and are firmly connected with stable signal transmission.

5.The main components are imported brands and have all undergone aging tests.

6.Equipped with a weighing module and controller for combined use, the load capacity data of each electric hoist is displayed intuitively and clearly through an electronic display screen. Enable operators to accurately grasp the load situation of the equipment and ensure operational safety.

7.The power supply is 380V 3ph+N+PE to ensure safe operation.

3.Multiple control gears for more comprehensive functionality and convenient use, equipped with emergency stop buttons for quick handling in emergency situations.

4.High quality aviation plugs are designed with grounding pins and insulation materials to effectively prevent current leakage and short circuits, and are firmly connected with stable signal transmission.

5.The main components are imported brands and have all undergone aging tests.

6.Equipped with a weighing module and controller for combined use, the load capacity data of each electric hoist is displayed intuitively and clearly through an electronic display screen. Enable operators to accurately grasp the load situation of the equipment and ensure operational safety.

7.The power supply is 380V 3ph+N+PE to ensure safe operation.

HGK-C-D Touch Screen Controller

1.The touch screen controller is a digital control system, and all control options are centralized on the LCD touch screen for digital display.

2.The controller can independently control the lifting and lowering of one or more electric hoists, and can group the purpose name and remarks for each point, saving the tedious operation of searching for layout drawings.

3.The ergonomically designed LCD control panel has a delicate appearance and simple operation.

4.The console and integrated circuit cabinet are designed in a separate manner, with only one signal line connected in the middle, increasing the convenience and flexibility of operation.

5.The handheld operation console is equipped with a joystick type operating lever, which can only be powered on when pushed up or pulled down. When not in operation, the joystick resets in the middle and stops sending action signals to the operating system, making the operation more controllable and safe.

6.The control panel is equipped with an emergency stop button, which can cut off the control system and power supply in an emergency manner to avoid safety accidents.

HGK-C-G Touch Screen Controller

1.The touch screen controller is a digital control system, and all control options are centralized on the LCD touch screen for digital display.

2.The controller can independently control the lifting and lowering of one or more electric hoists, and can group the purpose name and remarks for each point, saving the tedious operation of searching for layout drawings.

3.An ergonomically designed LCD control panel with a beautiful appearance and simple operation.

4.The console and integrated circuit cabinet are designed in a separate manner, connected by a signal line to increase the convenience and flexibility of operation (the theoretical distance of the signal line is 20O meters).

5.The handheld operation console is equipped with a joystick type operating lever, which can only be powered on when pushed up or pulled down. When not in operation, the joystick resets in the middle and stops sending action signals to the operating system, increasing the controllability and safety of the operation.

6.The control panel is equipped with an emergency stop button, which can cut off the control system and power supply in an emergency manner to avoid safety accidents.

7.

Note: The cabinet power supply is a 380V-3PH+N+PE three-phase five wire system

HGK-D

Sychronous Grouping

Controller

1.

The HGK-D series controller is a synchronous controller designed for fixed installation in specific locations, with a control voltage of 36V for the synchronous controller system.

2.All electrical appliances of the synchronous controller have undergone aging testing, and the main components are imported brands.

.3.Wall mounted cabinet, small in size, and can be customized with electric hoist points.

4.Set the jog and jog knobs to increase the convenience of operation.

5.The power supply is 220V and grounded, ensuring construction safety.

6.Wireless remote control is o

ptional.

HGK-G Sychronous Grouping Controller

1.The synchronous controller can handle 46 channels.

2.All electrical appliances of the synchronous controller have undergone aging testing, and the main components are imported brands.

3.The controller is a heavy-duty rotary directional switch that provides separate power supply for each electric hoist, increasing controllability. With a fast serial interface, it can achieve linkage between multiple controllers.

4.The outer shell design of the aviation box meets the needs of the mobile performance market, making it easy to carry and transport.

5.The power supply is 380V and grounded to ensure construction safety.

6.Wireless remote control is optional.

For More Intelligent Customization

PLC CONTROL SYSTEM

1.Integrated control in only one cabinet for power supply cables and signal lines.easy maintainence and commissioning.

2.Suitable for banquet,bar and theatre performances.

3.Built-in high performance vector frequency converter.Steady and smooth speed adjustment for lifting and descending.

4.Touch screen console can execute grouping control for each hoist lifting/descending and positioning,real-time lifting height display, static point positioning, etc.

5.Repeated positioning accuracy ±5mm.

6.Touch screen console is connected with PLC master electronic control cabinet,equipped with emergency stop and rocker handle for operation.

7.PLC system can store different scenarized application programs,or complete continuous actions for multiple styles. It can realize required stage action effects perfectly.

8.Console and master cabinet are designed and produced independently.It is more safe to help operator better visualization of hoists action scenes for real-time monitoring.

9.POWER SOURCE SUPPLY: 380V(L1+L2+L3+N+E)

2.Suitable for banquet,bar and theatre performances.

3.Built-in high performance vector frequency converter.Steady and smooth speed adjustment for lifting and descending.

4.Touch screen console can execute grouping control for each hoist lifting/descending and positioning,real-time lifting height display, static point positioning, etc.

5.Repeated positioning accuracy ±5mm.

6.Touch screen console is connected with PLC master electronic control cabinet,equipped with emergency stop and rocker handle for operation.

7.PLC system can store different scenarized application programs,or complete continuous actions for multiple styles. It can realize required stage action effects perfectly.

8.Console and master cabinet are designed and produced independently.It is more safe to help operator better visualization of hoists action scenes for real-time monitoring.

9.POWER SOURCE SUPPLY: 380V(L1+L2+L3+N+E)

ETHERNET PROGRAMMABLE CONTROL SYSTEM

1.Integrated design for drive system and control system.One signal line and one power line can control the whole system.

2.Distributed electric cabinets design. Each electric hoist is equiped with one slave control cabinet.Reduce too much wiring and signal interference.Quick installation.Suitable for touring performance.

3.Built-in high performance vector frequency converter. Smooth speed adjustment for steady lifting and descending. Particular motion speed is adjustable.

4.Slave control cabinets can be mounted on the truss with the mounting support frame. ISO standard connection ports. Plug and play without additional conversion.

5.Console has configuration panel and touch screen display.It can execute ramp start/stop, static point positioning,real-time display of lifting height,etc.

6.Repeated positioning accuracy ±1mm.

7.PLC master electronic control cabinet can measure the the electric hoists loading weight and monitor each hoist loading situation.If overload 120%, it will automatically cut off power supply to stop hoisting and send alert to change operation(optional).

8.Heavy loading connectors can transfer hoists position limit signal and encoder signals.

9.Max 100 meters console operation away from hoists is supported.

ETHENET MASTER ELECTRONIC CONTROL CABINET

1.Five cords plug-in connector to connect power source。Rated power supply voltage:380V(L1+L2+L3+N+PE).

2.CE 380V socket output.Each line 32A.Working with master control cabinet,it can complete different stage scenes like various styles, vertical lifting/descending and angles changing,etc.

3. 32A master power source output.One power source line can support 4-6 slave electronic control

cabinets.Less wiri

2.Distributed electric cabinets design. Each electric hoist is equiped with one slave control cabinet.Reduce too much wiring and signal interference.Quick installation.Suitable for touring performance.

3.Built-in high performance vector frequency converter. Smooth speed adjustment for steady lifting and descending. Particular motion speed is adjustable.

4.Slave control cabinets can be mounted on the truss with the mounting support frame. ISO standard connection ports. Plug and play without additional conversion.

5.Console has configuration panel and touch screen display.It can execute ramp start/stop, static point positioning,real-time display of lifting height,etc.

6.Repeated positioning accuracy ±1mm.

7.PLC master electronic control cabinet can measure the the electric hoists loading weight and monitor each hoist loading situation.If overload 120%, it will automatically cut off power supply to stop hoisting and send alert to change operation(optional).

8.Heavy loading connectors can transfer hoists position limit signal and encoder signals.

9.Max 100 meters console operation away from hoists is supported.

ETHENET MASTER ELECTRONIC CONTROL CABINET

1.Five cords plug-in connector to connect power source。Rated power supply voltage:380V(L1+L2+L3+N+PE).

2.CE 380V socket output.Each line 32A.Working with master control cabinet,it can complete different stage scenes like various styles, vertical lifting/descending and angles changing,etc.

3. 32A master power source output.One power source line can support 4-6 slave electronic control

cabinets.Less wiri

LOAD MONITORING SYSTEM

1.Dual-screen control, screen 1 displays the load monitoring, which can display the weight of each lifting point and play the role of safety observation. The operation panel is built-in, so that customers can better understand the dynamics of the lifting point.

2.Screen 2 is the electric hoist control display. All control options are concentrated on the LCD touch screen and displayed by digit. The controller can individually control the lifting of one or more electric hoists, and can group each point with a purpose name and a note , saving the tedious operation of finding layout drawings.

3.Ergonomically designed LCD console with exquisite appearance and simple operation.

4.The operation console and the integrated circuit cabinet are designed separately, and only one signal line is needed to connect in the middle, which increases the convenience and flexibility of operation.

5.The handheld console is equipped with a joystick-type operating lever. The electric hoist can only be powered on when it is pushed up or pulled down. When it is not in operation, the remote lever is reset to the middle and stops sending action signals to the operating system, making the operation more controllable. and security.

6.The operating console is equipped with an emergency stop button, which can cut off the control system and power supply in an emergency to avoid safety accidents.

7.The power supply of the cabinet is: 220V single three-cords system.

2.Screen 2 is the electric hoist control display. All control options are concentrated on the LCD touch screen and displayed by digit. The controller can individually control the lifting of one or more electric hoists, and can group each point with a purpose name and a note , saving the tedious operation of finding layout drawings.

3.Ergonomically designed LCD console with exquisite appearance and simple operation.

4.The operation console and the integrated circuit cabinet are designed separately, and only one signal line is needed to connect in the middle, which increases the convenience and flexibility of operation.

5.The handheld console is equipped with a joystick-type operating lever. The electric hoist can only be powered on when it is pushed up or pulled down. When it is not in operation, the remote lever is reset to the middle and stops sending action signals to the operating system, making the operation more controllable. and security.

6.The operating console is equipped with an emergency stop button, which can cut off the control system and power supply in an emergency to avoid safety accidents.

7.The power supply of the cabinet is: 220V single three-cords system.

INTELLIGENT ORBIT SYSTEM

1.The system includes hoist lifting point, controller, power cabinet and hoist chain slider.

2.Users can freely and flexibly realize the desired lighting layout design through the system, realize real-time dynamic program performance and record effects through the control software.

3.The system can integrates the real-time operation monitoring function and the abnormal error handling function to ensure the safety of the system.

4.The system can be flexibly expanded, easy to install and disassemble, and realize the hanging motion control from the simplest to the most complex, perfectly execute every detail of the performance, and integrate the safe operation of thesystem with artistic creation.

5.Applicable Scene,TV Station,Concert,Commercial.

2.Users can freely and flexibly realize the desired lighting layout design through the system, realize real-time dynamic program performance and record effects through the control software.

3.The system can integrates the real-time operation monitoring function and the abnormal error handling function to ensure the safety of the system.

4.The system can be flexibly expanded, easy to install and disassemble, and realize the hanging motion control from the simplest to the most complex, perfectly execute every detail of the performance, and integrate the safe operation of thesystem with artistic creation.

5.Applicable Scene,TV Station,Concert,Commercial.

Electric Hoist Flight Case(Optional)

1.The concave wheel well can be stacked with two cases.

2.Specially designed inner partition, stable and docile.

3.Design the internal structure according to the size of the gourd.

4.360-degree rotatable universal wheels, easier to carry.

5.Heavy-duty wheels have a reinforced case cover with diagonal brakes.

6.Compressed cotton is installed inside the box to effectively protect the surface of the electric hoist by spraying plastic.

7.The aluminum alloy frame is more durable.

8.Inline flight case handles.

9.External built-in cabinet lock, safe and does not take up space.

2.Specially designed inner partition, stable and docile.

3.Design the internal structure according to the size of the gourd.

4.360-degree rotatable universal wheels, easier to carry.

5.Heavy-duty wheels have a reinforced case cover with diagonal brakes.

6.Compressed cotton is installed inside the box to effectively protect the surface of the electric hoist by spraying plastic.

7.The aluminum alloy frame is more durable.

8.Inline flight case handles.

9.External built-in cabinet lock, safe and does not take up space.

Hot Searches