- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

ST-5029-CNC-6

-

Brand Name:

-

SmartTech

-

keyword:

-

CNC machining part

-

Material:

-

Aluminum,Copper,SS,ABS,PC,PP,PV,Nylon,POM,etc

-

Model Number::

-

ST-2022CNC

-

Application:

-

Household Product, Household Appliance,Industry, electronic products

-

Tolerance::

-

0.02-0.05mm

-

Surface Treatment::

-

painting sand blast electronic platingAnodic oxidation etc

-

Available file:

-

3D(IGS,STP,)2D(PDF,CAD,DWG)

-

OEM/ODM service:

-

YES

-

Color:

-

Customized

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, ABS,PP,PC,PVC,etc

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

ST-5029-CNC-6

-

Brand Name:

-

SmartTech

-

keyword:

-

CNC machining part

-

Material:

-

Aluminum,Copper,SS,ABS,PC,PP,PV,Nylon,POM,etc

-

Model Number::

-

ST-2022CNC

-

Application:

-

Household Product, Household Appliance,Industry, electronic products

-

Tolerance::

-

0.02-0.05mm

-

Surface Treatment::

-

painting sand blast electronic platingAnodic oxidation etc

-

Available file:

-

3D(IGS,STP,)2D(PDF,CAD,DWG)

-

OEM/ODM service:

-

YES

-

Color:

-

Customized

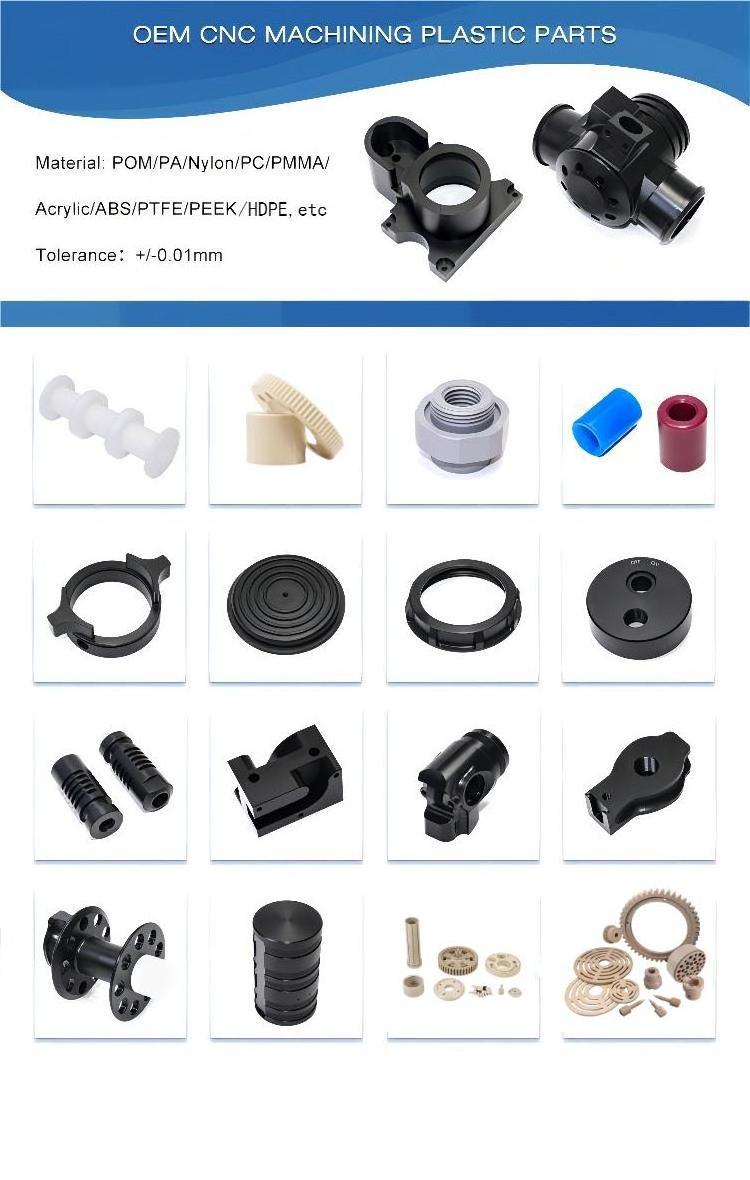

Customed plastic ,metal parts service ,factory price professional rapid prototype

|

Technique

|

CNC Machining Milling,Lathe,Drilling,Cutting ,etc

|

|

Surface treatment

|

polishing,anodizing, powder spraying, electroplating, etc

|

|

Material

|

ABS,PMMA,PEEK,HDPE,POM,PP,PU,PC,PVC,Aluminum,Copper,Stainless Steel,Iron etc

|

|

Drawing

|

2D drawing(CAD,PDF,DWG)3D drawing(stp,igs)

|

|

MOQ

|

1 set

|

Injection moulding,IML/IMD,Die Casting ,Investment Casting,Sand/Gravity Casting ,Forging , Stamping mould, rubber injection mould service etc.

Product range:

Electronic , Industry,Automotive , Medical device, Home appliance Products, etc .

|

Technique

|

Material

|

Tolerance

|

|

CNC Machining

|

ABS,PMMA,PEEK,HDPE,POM,PP,PU,PC,PVC,aluminum,copper,iron etc

|

+/-0.005"

|

|

Silicone mold/vacuum

|

ABS, PP, PC, PMMA, POM, Nylon ,PU etc

|

+/-0.003"

|

|

Injection molding

|

ABS,PMMA,POM,PP,PU,PC,PA66,PMMA,PVC,PVE

|

+/-0.001"

|

|

Lost wax casting

Sand casting,gravity casting

|

Aluminum,Stainless Steel,Carbon Steel,Brass, Copper, Nickel Alloys, Copper etc

|

+/-0.05"

|

|

Forging

|

steel, cast iron, low carbon steel, stainless steel,

|

+/-0.05"

|

|

Die casting

|

aluminum,Zinc alloy, magnesium alloy,brass, copper,etc

|

+/-0.03"

|

|

Surface finishing

|

Painting, polishing, electroplating, chrome plating, powder coating, anodizing, transparent,Laser engraving

|

+/-0.005"

|

3.Smart is including R&D center, tooling, molding, silkscreen, spraying workshops and assembly line.

Producing capability: We have a excellent team of specialists and advanced engineers. R&D department has 50 engineers, the department of mould manufacturing, 100 professional mould makers .

Producing capability

We have a excellent team of specialists and undergratuates and advanced engineers. R&D department has 3 ID, 6 MD, and 100 engineers, the department of mould manufacturing, 120 professional mould makers.

Customers visit our factory

1.Lead time:

Generally the processing time is 4-12 days. More accurate time is depend on your products.

Delivery time is about 3-7 days.

2. Express Company: DHL, TNT, UPS, FEDEX, EMS etc.

3. Package Informations:

standard carton box, according to your requirement.

Contacts: Mr Alex

Tel: +86-13267109366 skype:smarttechcn Email:alexshen(at)smarttechcn.com