- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

13month

-

Brand Name:

-

Suncenter

-

Model Number:

-

DGS-DGT25

-

Place of Origin:

-

Guangdong, China

-

Horsepower:

-

10hp

-

Cable Length:

-

none

-

Outlet Size:

-

none

-

Power:

-

High Pressure

-

Product name:

-

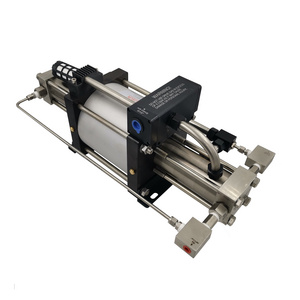

high pressure Oxygen filling booster unit

-

Model:

-

DGS-DGT25

-

Boost Ratio:

-

25:1

-

Max Flow:

-

156lpm

-

Max pressure:

-

200bar

-

min gas inlet pressure:

-

0.1bar

-

driven air pressure:

-

2-8bar

-

certificate:

-

ce

-

packing:

-

wooden case

Quick Details

-

Application:

-

Mining industry

-

Pressure:

-

High Pressure

-

Voltage:

-

High Pressure

-

Warranty:

-

13month

-

Brand Name:

-

Suncenter

-

Model Number:

-

DGS-DGT25

-

Place of Origin:

-

Guangdong, China

-

Horsepower:

-

10hp

-

Cable Length:

-

none

-

Outlet Size:

-

none

-

Power:

-

High Pressure

-

Product name:

-

high pressure Oxygen filling booster unit

-

Model:

-

DGS-DGT25

-

Boost Ratio:

-

25:1

-

Max Flow:

-

156lpm

-

Max pressure:

-

200bar

-

min gas inlet pressure:

-

0.1bar

-

driven air pressure:

-

2-8bar

-

certificate:

-

ce

-

packing:

-

wooden case

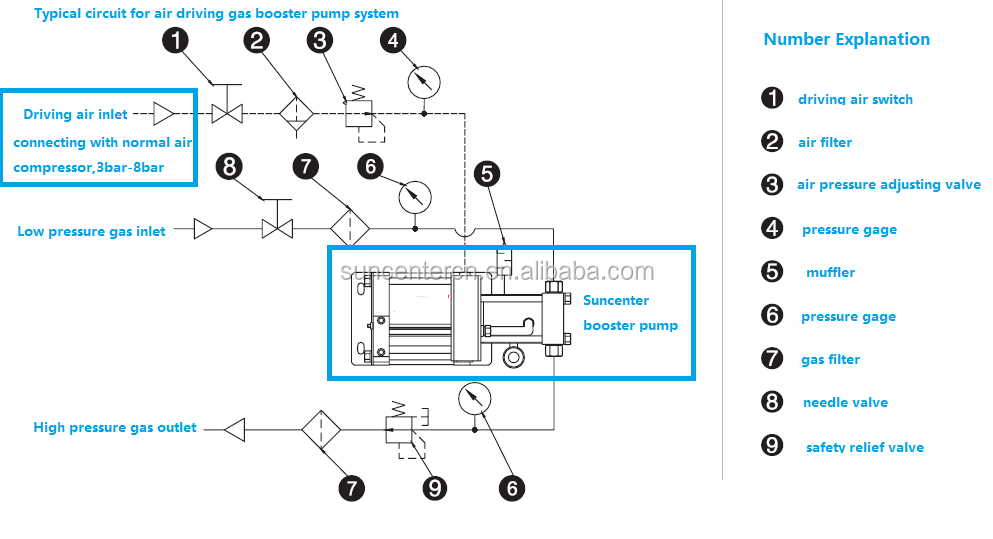

Gas booster pump system

Suncenter - Gas booster systems are compact and delicacy solution tailored to customer specific requirements with gas boosters as well as all accessories to be fitted and installed in the frame or a closed cabinet.

To operate this system, the pressure gauges, valves and pressure regulators have to be fitted on panels. The outlet pressure is easily to be set through a simple air regulator.

The pump stops automatically when this end pressure is reached and restarts with a slight drop in the outlet pressure or an increase in the air drive pressure.

Suncenter - Pneumatic booster system are used for oil free compression of clean shop air as well as industrial gases like Argon, Helium, Oxygen, Hydrogen and Nitrogen,CO2, etc..Driven air from 3 bar to 8 bar (from air compressor).

Operating pressure up to 80 MPa, for higher pressure, pump with double driven heads is an ideal option.

Applications

Pressure test with gas

Gas transfer and filling

(Argon/Helium/Hydrogen/Oxygen/Nitrogen/CO22/CH4/LNG/LPG/CNG/FM200 etc.)

Charging of gas cylinder and accumulator with nitrogen

Supply for isolating gas systems

Gas assisted injection molding

Transfer of oxygen cylinders

Charging of breathing air bottles

Leak test

Hydrostatic Testing for valves, tanks, pressure vessels, pressure switches, hoses, pipes and tubing, pressure gauges, cylinders, transducers, well casings, BOPs, gas bottles and air craft components

Safety valve adjusting

Suncenter DGS Series Pneumatic (Air driven) Gas Booster System

DGS gas booster system = booster pump+ following valves, gages, and parts

The hottest selling- model A and model C cabinet picture

The standard gas booster system including following parts:

Technical specification for DGS-DGA Series:

(Note: PL: driven air pressure PA: gas inlet pressure PB: gas outlet pressure)

|

Model

|

Pressure boost ratio

|

Min. gas

Inlet pressure PA (bar) |

Max.gas

Inlet pressure PA (bar) |

Max. gas

outlet pressure PB (bar) |

Driven air pressure PL

|

Formula to

calculate gas outlet pressure PB |

Connection:

Gas Inlet / Gas outlet (NPT thread) |

Max. flow at driven air pressure of 6bar (L/min)

|

|

DGS-DGA02

|

2:1

|

1.0

|

16

|

16

|

2bar-8 bar

|

2X PL

|

1/2 / 1/2

|

960 (at PA of 6 bar )

|

|

DGS-DGA05

|

5:1

|

0

|

40

|

40

|

2bar-8 bar

|

5XPL

|

1/2 / 1/2

|

680(at PA of 6 bar )

|

|

DGS-DGA06

|

6:1

|

2.0

|

48

|

48

|

2bar-8 bar

|

6XPL

|

1/2 / 1/2

|

360(at PA of 10 bar )

|

|

DGS-DGA10

|

10:1

|

3.5

|

80

|

80

|

2bar-8 bar

|

10XPL

|

3/8/ 3/8

|

210(at PA of 10 bar )

|

|

DGS-DGA15

|

15:1

|

3.5

|

120

|

120

|

2bar-8 bar

|

15XPL

|

3/8/ 3/8

|

190(at PA of 10 bar )

|

|

DGS-DGA25

|

25:1

|

7.0

|

200

|

200

|

2bar-8 bar

|

25XPL

|

1/4/ 1/4

|

120(at PA of 20 bar )

|

|

DGS-DGA40

|

40:1

|

10

|

320

|

320

|

2bar-8 bar

|

40XPL

|

1/4/ 1/4

|

200(at PA of 40 bar )

|

|

DGS-DGA60

|

60:1

|

20

|

480

|

480

|

2bar-8 bar

|

60XPL

|

1/4/ 1/4

|

180(at PA of 40 bar )

|

|

DGS-DGA100

|

100:1

|

25

|

800

|

800

|

2bar-8 bar

|

100XPL

|

1/4/ M14X1.5

|

136(at PA of 40 bar )

|

Technical specification for DGS-DGD Series:

(Note: PL: driven air pressure PA: gas inlet pressure PB: gas outlet pressure)

|

Model

|

Pressure boost ratio

|

Min. gas

Inlet pressure PA (bar) |

Max.gas

Inlet pressure PA (bar) |

Max. gas

outlet pressure PB (bar) |

Driven air pressure PL

|

Formula to

calculate gas outlet pressure PB |

Connection:

Gas Inlet / Gas outlet (NPT thread) |

Max. flow at driven air pressure of 6bar (L/min)

|

|

DGS-DGD10

|

10:1

|

3.5

|

80

|

80

|

2bar-8 bar

|

10XPL+ PA

|

3/8/3/8

|

410(at PA of 6 bar )

|

|

DGS-DGD15

|

15:1

|

5

|

120

|

120

|

2bar-8 bar

|

15XPL+ PA

|

3/8/3/8

|

350 (at PA of 6 bar )

|

|

DGS-DGD25

|

25:1

|

10

|

200

|

200

|

2bar-8 bar

|

25XPL+ PA

|

1/4/1/4

|

396(at PA of 20 bar )

|

|

DGS-DGD40

|

40:1

|

15

|

320

|

320

|

2bar-8 bar

|

40XPL+ PA

|

1/4/1/4

|

320(at PA of 40 bar )

|

|

DGS-DGD60

|

60:1

|

25

|

480

|

480

|

2bar-8 bar

|

60XPL+ PA

|

1/4/1/4

|

215(at PA of 40 bar )

|

|

DGS-DGD100

|

100:1

|

35

|

800

|

800

|

2bar-8 bar

|

100XPL+ PA

|

1/4/M14*1.5

|

300(at PA of 60 bar )

|

|

DGS-DGD130

|

130:1

|

50

|

1040

|

1040

|

2bar-8 bar

|

130XPL+ PA

|

1/4/M14*1.5

|

180(at PA of 60 bar )

|

Technical specification for DGS-DGT Series:

(Note: PL: driven air pressure PA: gas inlet pressure PB: gas outlet pressure)

|

Model

|

Pressure boost ratio

|

Min. gas

Inlet pressure PA (bar) |

Max.gas

Inlet pressure PA (bar) |

Max. gas

outlet pressure PB (bar) |

Driven air pressure PL

|

Formula to

calculate gas outlet pressure PB |

Connection:

Gas Inlet / Gas outlet (NPT thread) |

Max. flow at driven air pressure of 6bar (L/min)

|

|

DGS-DGT15

|

15:1

|

0.1

|

56

|

120

|

2-8 bar

|

15XPL

|

3/8/ 1/4

|

230(at PA of 8 bar )

|

|

DGS-DGT25

|

25:1

|

0.1

|

10

|

200

|

2-8 bar

|

25XPL

|

3/8/ 1/4

|

156(at PA of 8 bar )

|

|

DGS-DGT7/25

|

25:1

|

5

|

56

|

200

|

2-8 bar

|

25XPL

|

3/8/ 1/4

|

156(at PA of 8 bar )

|

|

DGS-DGT40

|

40:1

|

0.1

|

10

|

320

|

2-8 bar

|

40XPL

|

3/8/ 1/4

|

124(at PA of 8 bar )

|

|

DGS-DGT15/40

|

40:1

|

5

|

120

|

320

|

2-8 bar

|

40XPL

|

3/8/ 1/4

|

124(at PA of 8 bar )

|

|

DGS-DGT60

|

60:1

|

0.1

|

10

|

480

|

2-8 bar

|

60XPL

|

3/8/ 1/4

|

80(at PA of 15 bar )

|

|

DGS-DGT15/60

|

60:1

|

6

|

120

|

480

|

2-8 bar

|

60XPL

|

3/8/ 1/4

|

80(at PA of 15 bar )

|

|

DGS-DGT100

|

100:1

|

0.1

|

10

|

800

|

2-8 bar

|

100XPL

|

3/8/ 1/4

|

63(at PA of 8 bar )

|

Technical specification for DGS-2DGT series:

(Note: PL: driven air pressure PA: gas inlet pressure PB: gas outlet pressure)

|

Model

|

Pressure boost ratio

|

Min. gas

Inlet pressure PA (bar) |

Max.gas

Inlet pressure PA (bar) |

Max. gas

outlet pressure PB (bar) |

Driven air pressure PL

|

Formula to

calculate gas outlet pressure PB |

Connection:

Gas Inlet / Gas outlet (NPT thread) |

Max. flow at driven air pressure of 6bar (L/min)

|

|

DGS-2DGT7/15

|

15:1

|

4

|

56

|

120

|

2bar-8 bar

|

15XPL

|

3/8 / 3/8

|

430(at PA of 10 bar )

|

|

DGS-2DGT7/25

|

25:1

|

5

|

56

|

200

|

2bar-8 bar

|

25XPL

|

3/8 / 3/8

|

300(at PA of 10 bar )

|

|

DGS-2DGT15/40

|

40:1

|

7

|

120

|

320

|

2bar-8 bar

|

40XPL

|

3/8 / 3/8

|

180(at PA of 10 bar )

|

|

DGS-2DGT15/60

|

60:1

|

7

|

120

|

480

|

2bar-8 bar

|

60XPL

|

3/8 / 3/8

|

120(at PA of 10 bar )

|

Note: PL: driven air pressure PA: gas inlet pressure PB: gas outlet pressure

In order to extend the lifetime of the pump, the driven air pressure should not be higher than 8 bar

DGS series gas boosters working pictures

DGS-DGD40 gas booster system for nitrogen gas spring filling

DGS-DGT series gas boosters for gas cylinder transfer and filling

Packing&Shipping

Package: pack in plywood case

Shipment: by air/sea/express

Company Introduction

Dongguan Suncenter Fluid Control Equipment Co., Ltd

is the member company of Suncenter Group, which is located in Dongguan city of

Guangdong province in China. With more than 15 years experiences in fluid pressure exchange and controlling field, we provide

various kinds of pneumatic and hydraulic booster pumps, systems and solutions to the customers all over the world. Due to our best

product quality, competitive price as well as excellent after-sales service, we have win a great reputation in the field.

Our main products including

:

1. High Pressure Booster Pumps ( Gas Booster Pump, Air Driven Liquid Pump, Air Amplifiers)

2. High Pressure Systems (Gas/Liquid Booster System,Hydro test bench,Chemical injection system,CO2/FM200 filling machine, Tube

Expanding Machine)

3. High Pressure Test Equipment(Hydraulic/Burst/Hydrostatic test machine,Cylinder test machine, Valve test bench,Impulse Testing

Machine, etc.)

4. Hydro-pneumatic cylinders and machines(pneumatic hydraulic cylinders,pneumatic riveting machines,pneumatic press machines etc.)

Customer review

Hot Searches