- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

23KW

-

Weight (KG):

-

5000

-

Raw material:

-

Wood Chips, Sawdust, Rice Husk, Straw

-

Product name:

-

coffee grounds carbon fiber wood coal fired carbonization furnace

-

Usage:

-

Charcoal Maker

-

Advantage:

-

Continuous Working Environment Friendly

-

Fuel:

-

Firewood Coal Gas Natural Gas

-

Final product:

-

Sawdust Charcoal

-

Operation:

-

Automatic

-

Key Words:

-

Continuous Carbonization Furnace

-

Installation:

-

Engineer Guide

-

Carbonization time:

-

1 Hour

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sanjin

-

Dimension(L*W*H):

-

10*1*1m

-

Voltage:

-

380v

-

Power:

-

23KW

-

Weight (KG):

-

5000

-

Raw material:

-

Wood Chips, Sawdust, Rice Husk, Straw

-

Product name:

-

coffee grounds carbon fiber wood coal fired carbonization furnace

-

Usage:

-

Charcoal Maker

-

Advantage:

-

Continuous Working Environment Friendly

-

Fuel:

-

Firewood Coal Gas Natural Gas

-

Final product:

-

Sawdust Charcoal

-

Operation:

-

Automatic

-

Key Words:

-

Continuous Carbonization Furnace

-

Installation:

-

Engineer Guide

-

Carbonization time:

-

1 Hour

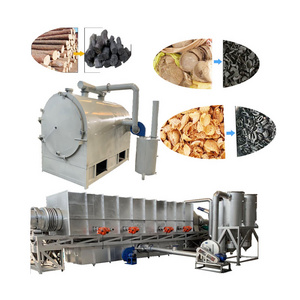

Continuous charcoal making machine kiln carbonization furnace sawdust

coconut shell coffee grounds carbon fiber wood coal fired

The continuous carbonization furnace is mainly used for the carbonization of biomass materials. The equipment is still using the principle of gasification carbonization and adopts advanced smoke-free environmental carbonization process:The whole set of equipment consists of gasification system (liquefied gas gasification machine), purification system (spray tower, cyclone dust removal, water cooling, oil water separator, fine filter) and control system (control cabinet). The whole carbonization process is automated production, automated operation.

Different from the energy-saving and environmentally-friendly continuous carbonization machine, it has two significant advantages: First, the main machine has a large volume, high carbonization rate, and strong production capacity, and can be produce 0.3-0.8 tons of carbonized products per hour;

Second, the cost is low and the practicability is strong, which satisfies the objective requirements of the initial small entrepreneurs' investment and small benefits. The carbonization machine is a carbonized wood material such as wood chips, rice husks, peanut shells, plant straws, bamboo chips, coconut shells, palm shells, bark, etc. (volumes of less than 10 cm in size) are subjected to dry distillation under high temperature conditions in the furnace, Ideal equipment for oxygenation and high carbonization rates.

|

Model

|

LXT-1000

|

LXT-1200

|

|

|

Feed power

|

3kw+1.1kw

|

3kw+2.2kw

|

|

|

Cooling and discharge power

|

3kw+3kw

|

3kw+3kw

|

|

|

Drive motor

|

5.5kw

|

7.5kw

|

|

|

Fan motor

|

7.5kw

|

11kw

|

|

|

Diameter*length

|

1m*12m

|

1.2m*12m

|

|

|

Output capacity

|

600-800kg/h

|

800-1200kg/h

|

|

|

Working continuously

|

24H

|

|

|

|

The feed temperature

|

350-450℃

|

|

|

|

The raw material size

|

≤3cm

|

|

|

|

The raw material moisture

|

≤15%

|

|

|

According to this method of circulation, sufficient to achieve self-sufficient, then achieve the effect of energy-saving.The flue gas through purification, to reach the environment production and flue gas emissions-free. Which is reached to the standards of waste gas emptying. The whole carbonization process is automated production, automated operation.

A: In order to design a solution and offer the quotation, we need the following information.1 the raw material 2 the size of the raw material before crushing by inch or mm 3 the finished product size by inch or mm 4 the production capacity by tons per hour.

Q: How long will I get the answer from you if I give the inquiry?

A:Upon receiving your inquiry, we will answer you in 24 hours.

Q: What about the payment terms?

A:30% by TT as deposit on signing the contract, 70% by as final payment of balance after the client’s satisfactory inspection of the equipment prior to the goods leaving the factory.

Q: How long is the warranty?

A: The warranty period for structural and mechanical equipment is one year. The warranty period for all electric motors is 3 years. Wear parts are not covered by warranty unless the component part is found to be flawed.

Q: Do you provide overseas installation service?

A: Yes. If you buy machines from us, we will dispatch the most professional engineer to your local site to guide the installation. After the installation, the engineer will also do the commissioning and train the workers to operate the machines, and do the maintenance

Q:.Is the spare parts available?

A: Yes. The spare parts are available. We will give you a 5% discount if you buy from us at the basis of our best price.

Q: How to deliver the spare parts?

A: the spare parts will be packed in wooden case. Generally the spare parts will be sent by sea, but if you need it urgently, we will deliver by air.

Q: What is the lead time?

A: If we have in stock, the machine will be delivered in 3-7 working days after we will the down payment.( the motor needs to be customized as per your local voltage and frequency). If not, it needs 10-30 working days.

Q: What is about your after sales service?

A: Should any problems occur, our team of Engineers and Technicians will respond within 12 hours of notice by the client. If the problems still can not be solved, we will send the engineers to your site to solve the problem.