- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 400*150*200 mm, 240*115*90 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

Adjustable

-

Dimension(L*W*H):

-

2750*2504*1359MM

-

Warranty:

-

1Years

-

Marketing Type:

-

Hot Product 2020

-

Weight (KG):

-

3000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Fire Rating:

-

4

-

Panel Thickness:

-

50-200mm

-

Panel Size:

-

2000-3000mm

-

Multifunctional:

-

Can Produce Different Thickness and Length

-

Color:

-

Changable

-

Raw material:

-

Polystyrene Foam(EPS), Additives, Fly Ash, Water,panel,etc

-

Product Name:

-

lightweight concrete panel machine

-

Application:

-

Laser Engraving, Plates, Machinery & Hardware

-

other name:

-

sandwich panel making machine

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, lightweight concrete wall panel forming machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 12000 pcs/8hours, 8-16pcs/time

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 400*150*200 mm, 240*115*90 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

Adjustable

-

Dimension(L*W*H):

-

2750*2504*1359MM

-

Warranty:

-

1Years

-

Marketing Type:

-

Hot Product 2020

-

Weight (KG):

-

3000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Fire Rating:

-

4

-

Panel Thickness:

-

50-200mm

-

Panel Size:

-

2000-3000mm

-

Multifunctional:

-

Can Produce Different Thickness and Length

-

Color:

-

Changable

-

Raw material:

-

Polystyrene Foam(EPS), Additives, Fly Ash, Water,panel,etc

-

Product Name:

-

lightweight concrete panel machine

-

Application:

-

Laser Engraving, Plates, Machinery & Hardware

-

other name:

-

sandwich panel making machine

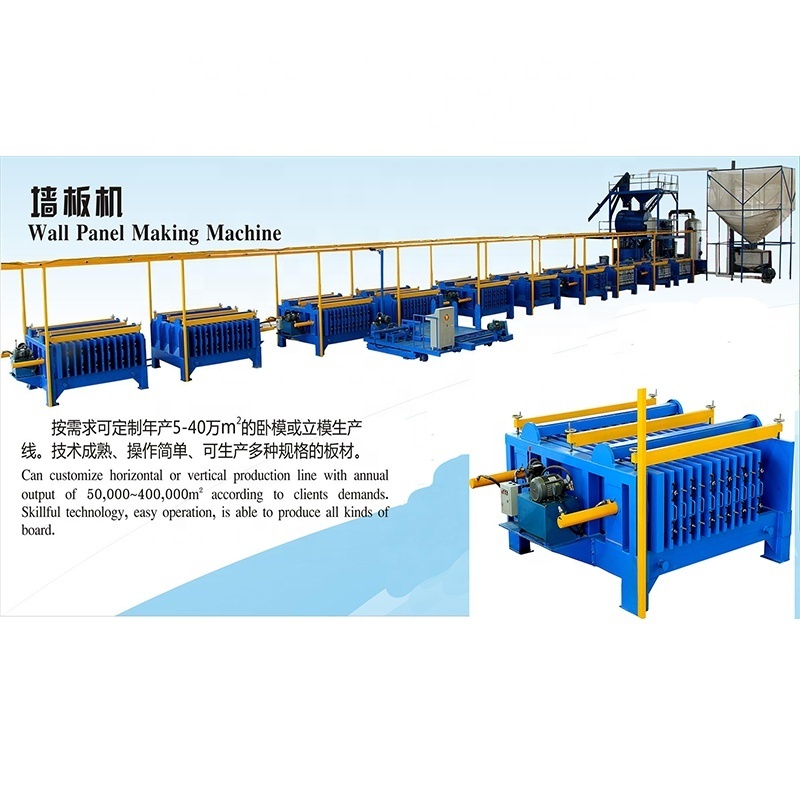

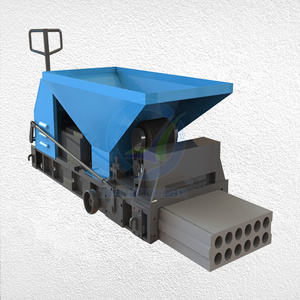

HFP512A EPS automatic lightweight concrete sandwich wall panel making machine lightweight concrete wall panel forming machine

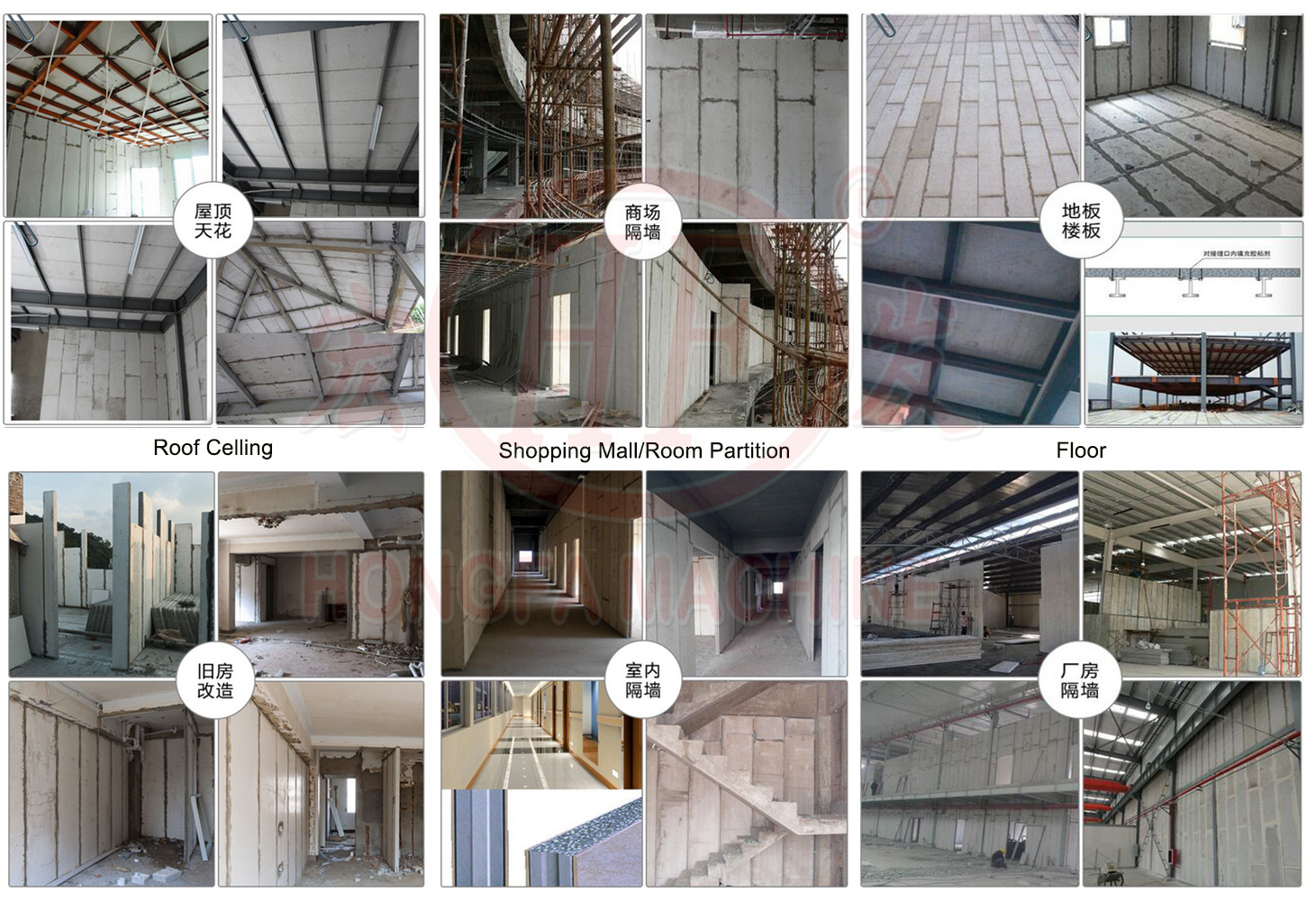

Wall panel application

Precast calsium silicate board eps sandwich wall panel cement concrete fence wall machine

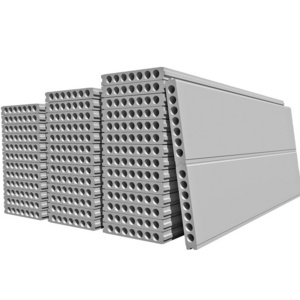

EPS sandwich lightweight wall panel is widely used for various buildings, such us residential building, hospital, school, hotel etc. Precast concrete sandwich wall panel has many advantages compared to traditional concrete blocks, such as fire-proof, sound-insulation, anti-bending, water-proof, heat-insulation etc., also it can be arbitrary cut according to different sizes demand.

Because of its so many features, it can reduce total cost of engineering and achieve fast construction. For example, 75mm thickness sandwich panel can replace 120mm concrete block, so as a partition building material, it can bring much more room space than thicker concrete blocks.

1.Main Feasture:

(1) The machine adopts PLC and touch screen control, automatic filling, electronic weighing, temperature control, material level control to realize automatic production.

(2) With the same machine, it can adjust the panel size and thickness. The thickness will be from 60 to 180mm.

(3) The closed constant pressure foamng barrel features of high heating efficiency and saves stem.

(4) High precise guiding pressure reducing valve controls the temperature and steam pressure of the

closed barrel, ensuring the outcome pressure of the valve constant and the inner temperature controlled

wihin ±1%, which keeps the foamed material equal and prevents the bead agglomerate because of the

bad temperature control.

(5) With photoelectric or vibration sensor to control material level, ensuring density tolerance within ±3%.

(6) The machine is equipped with fluidized bed dryer, including drying, automatic sieving, depluming and

material conveying to silos.

(7) Most components are of world-famous brands, with reliable performance, stable quality, long service

life and low maintenance cost.

(8) The machine can realize the primary and second expansion

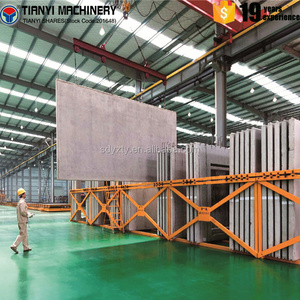

Introduction of Hongfa EPS light weight wall panel production line

1. Materials of Hongfa Brand EPS Wall Panel

Core Material: EPS( Foam polystyrene, Cement and fly ash.)

Board materials: Calcium Silicate Board.

2. Common Specifications of EPS cement wall sandwich panel

L*W*T: 2440mm*610mm*50mm/60mm/75mm/90mm/100mm/120mm/150mm.

2270mm* 610mm*50mm/60mm/75mm/90mm/100mm/120mm/150mm/180mm.

3. Applied range of light weight EPS wall panel

For interior and exterior wall partition on steel or concrete structure building, new construction or renovations. It can be widely applied to wall materials of various high and low buildings such as bank, office building, hospital, school, hotel, shopping mall, amusement, old house reconstruction, residence and workshop.

4. Advantages of Hongfa wall sandwich panel

A:Light weight

B:Excellent sound insulation

C:Heat Insulation

D:Waterproof Fire proof

E:Energy Efficient Environmental

F:Convenient construction

G:High Intensity without deformation.

Raw Materials Proportion:

| Cement | Sand | Mineral admixtures | Water | Addictive | Eps (M3) |

| 1 | 1.0 - 2.0 | 0.5 - 1.2 | 0.55 - 0.65 | 0.04 - 0.06 | 0.5 - 0.85m3 |

| weight ratio | Volume per M3 | ||||

Reference Workers needed:

(

take capacity 200,000/yearly as example

)

Raw materials, boiler and EPS expending

:

1

Mixing

:

1

Pouring

:

1

Pre insert silica panel

:

1

Demoulding

:

1

Total:

5

Delivery time: Within 40 days after receipt of deposit and moulds confirmation from buyer

1.Guarantee for one year and after sale service for whole life.To offer free design,free technology support and free machine maintenance trainning.

2.We will provide you with a set of spare parts for free!