- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

High vacuum stainless steel chamber:

-

Approx.dia.300mm*300mm

-

Inspection window and flanges:

-

RF100

-

Rotating substrate frock:

-

dia.4 inches substrate stage

-

Substrate stage heating system:

-

Room temperature to 500℃, controllable and adjustable

-

Chamber barking:

-

Barking temperature: 100℃

-

Molecular pump:

-

600L/s

-

Mechanical Pump:

-

4L/S

-

High quality flow controller:

-

Rang 0-100SCCM Range 0-20SCCM

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

Certification:

-

CE ISO9001

Quick Details

-

Machine Type:

-

vacuum Coating System

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

DX

-

Voltage:

-

380V

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

High vacuum stainless steel chamber:

-

Approx.dia.300mm*300mm

-

Inspection window and flanges:

-

RF100

-

Rotating substrate frock:

-

dia.4 inches substrate stage

-

Substrate stage heating system:

-

Room temperature to 500℃, controllable and adjustable

-

Chamber barking:

-

Barking temperature: 100℃

-

Molecular pump:

-

600L/s

-

Mechanical Pump:

-

4L/S

-

High quality flow controller:

-

Rang 0-100SCCM Range 0-20SCCM

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

Certification:

-

CE ISO9001

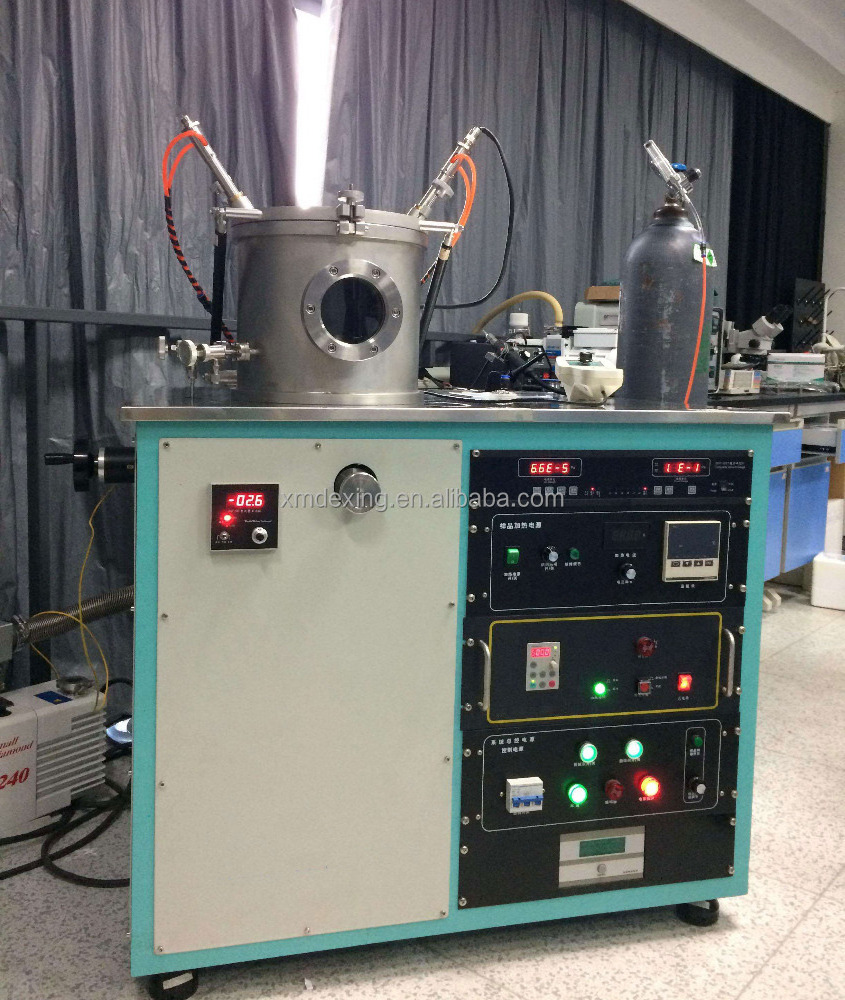

DXV-300 Magnetron Sputtering Machine

Introduction

The system is a high vacuum multifunctional three target magnetron sputtering machine. It is apply for the preparation of nanoscale monolayer and multilayer functional film and composite membrane, which could coat metal film, alloy membrane, compound membrane, semiconductor membrane, ceramic membrane (need radio-frequency power supply), dielectric composite membrane and other chemical reaction film. System mainly consist of sputtering chamber, permanent magnet magnetron sputtering targets ( three targets), full-automatically matching RF power supply, DC power supply, sample stage, sample heating furnace, pump exhausting, vacuum measuring system, gas system, electrically control system and so on.

- Ultimate Vacuum of Sputtering Chamber: ≤ 6.67*10 -5 Pa ( after continuously baking and degassing)

Vacuum acquisition adopts molecular pump (600L/S), high quality mechanical pump (4L/S) and CF manual gate valve, which has the characteristics of quick speed to gain high vacuum environment and offer cleanliness of film.

Leak Detection Rate of System ≤ 5.0*10 -7 Pa.l/S

System begins air exhausting from atmosphere and sputtering could reach 6.6*10 -4 Pa in 25 minutes.

Vacuum Degree ≤ 5Pa after stopping pumping 12 hours

- Sputtering chamber is equipped with 2 set 2 inches high performance permanent magnet confocal magnetron sputtering target. Each target could independently or in order or together works. Magnetron target is cooled by water and adopts target upward and sputtering downward into film. RF, DC and MF of magnetron target could be compatible, which could sputter magnetic materials. The magnetron target has the structure of manual baffle.

- The sample stage is in the bottom of vacuum chamber, where could put one pieces 4 inches sample at MAX. The sample has the function of continuously rotating, rotating 0-30r/m. which is continuous and adjustable.

- The heating device heats on the imported resistance wire. The heating temperature: -500℃. It is controlled by thermocouple closed and feedback, which is adjustable and controllable.

- Vacuum measurement adopts compound vacuum gauge.

- System is equipped with two-way input red-y compact series MFC control air intake system (Ar 02). The flow is 100SCCM and 20SCCM.

- The pressure control of coating technology adopts manual gate valve and imported MFC control.

- System is equipped with one set 500W full-automatic matching RF power supply.

- System is equipped with one set imported 500W power supply.

- System is equipped with film thickness monitor.

Function and Composition of System

This system is single chamber structure, mainly consist of sputtering chamber, magnetron sputtering target, rotation substrate stage, heating system, imported DC power supply, automatic RF power supply, working air channel, vacuum acquisition system, installation cabinet, vacuum measuring system, water cooling, alarm system and control system, which could apply for metal film and dielectric film.

Main components and Technical Index of Equipment

Ultimate Vacuum of Sputtering Chamber: 6.6*10 -5 Pa ( after continuously baking and degassing)

Leak Detection Rate of System < 5.0*10 -7 Pa.l/S

System begins air exhausting from atmosphere and sputtering could reach 6.6*10 -4 Pa in 25 minutes.

Vacuum Degree ≤ 5Pa after stopping pumping 12 hours

1. Sputtering Vacuum System 1 set

Vacuum chamber is upright and up cover structure, size: φ 300mm*300mm, made of stainless steel, argon arc welding, surface after electrochemical polishing passivating treatment. Connections adopt metal washer or fluoro-rubber to seal. The chamber is opened by air cylinder which make easily for change of targets. Various of flanges of chamber as following:

|

Name |

Model |

Qty |

Application |

|

flange connector |

RF100 |

1 |

connect to viewing port |

|

flange connector |

CF16 |

2 |

1 channel intake-tube, deflation valve |

|

flange connector |

CF100 |

1 |

connect to molecular pump |

|

flange connector |

RF300 |

1 |

For installing magnetron target and target baffle |

|

sample stage flange connector |

|

1 |

To install sample stage |

|

flange connector |

CF35 |

1 |

connect to side pump |

2. Magnetron Sputtering System 3 sets

2.1 Target size: 2 inches

2.2 Offer targets: 3 stainless steel testing targets

2.3 Permanent magnet target (it is compatible with magnetic materials), RF sputtering and DC sputtering are compatible. Water cooling in target.

2.4 Assembly of manual control baffle: 3 sets

2.5 Target on the above, sputtering downwards, confocal magnetron sputtering target. Each targets could independently or in order work.

2.6 500W full-automatic matching RF power supply 1 set

2.7 500W DC power supply one set.

3. Rotating substrate stage 1 set

3.1 The size and quantity of substrate: 4 inches sample, one piece for each

3.2 The substrate is heated by imported heater strip. The heating temperature: room temperature-500℃,which is controlled by thermocouple closed loop feedback, and adjustable and continuous.

3.3 The rotation of substrate is driven by motor, 0-30 r/m, continuously adjustable.

4. Window and components of flange interfaces 1 set

4.1 RF100 glass window: 1 piece

4.2 CF35 ceramics sealing-in feedthrough flange (lighting and inside baking lead): 1 piece

4.3 Blank flange: CF35 one piece

5. Heating device 1 set

The heating device is on the flange on the bottom of vacuum chamber, which achieve closed-loop-control by thermocouple to control temperature control power supply.

6. Working gas circuit 1 set

6.1 100SCCM, 20sccm mass flow controller, CF16 manual globe valve, pipeline, connectors and so on, together 2 channels

6.2 DN16 manual inflation valve, pipeline, connectors and so on: 2 channels

7. Air bleed set, valve and pipeline 1 set

7.1 compound molecular pump and frequency conversion control power supply: 1 set

7.2 Mechanical pump: 4L/S 1 set

7.3 DN40 electric check valve: 1 set

7.4 Side pipe channel of molecular pump and mechanical pump: 1 set

7.5 CC100 manual gate valve: 1 set (used for separating compound molecular pump and mechanical pump).

7.6 Differential pressure inflation valve: 1 set

8. Installation machine assembly 1 set

It is made by welding of excellent square steel. The surface is spraying process. The surface of machine is decorated by stainless steel skin. It has four trundles which could be moved or fixed.

Cable bearer: 1 set

9. Vacuum Measurement 1 set

The sputtering vacuum adopts ZDF5227 compound meter to measure.

10. Spare parts 1 set

11. Control model: manual operation control 1 set

12. Film thickness detector 1 set

Configuration

|

NO. |

Name |

Parameters |

Quantity |

|

1 |

High vacuum stainless steel chamber |

Approx.φ300mm*300mm |

1 set |

|

2 |

Antifouling lining of Chamber |

|

1 set |

|

3 |

Inspection window and flanges |

RF100 |

1 set |

|

4 |

Chamber illumination |

|

1 piece |

|

5 |

Rotating substrate frock |

Φ4 inches substrate stage |

1 set |

|

6 |

Rotating motor and power supply |

|

1 set |

|

7 |

Substrate stage heating system |

Room temperature to 500℃, controllable and adjustable |

1 set |

|

8 |

Chamber barking |

Barking temperature: 100℃ |

1 set |

|

9 |

Temperature measuring, control system |

Temperature controller, PID temperature control, adjustable and controllable |

1 set |

|

10 |

Electrode |

CF35 four cores |

1 set |

|

11 |

Molecular pump |

600L/s |

1 set |

|

12 |

Mechanical Pump |

4L/S |

1 set |

|

13 |

Manual gate valve |

CC-100 |

1 set |

|

14 |

Electric check valve |

DF40 |

1 piece |

|

15 |

Side pump angle valve |

CF35 |

1 piece |

|

16 |

CF16check valve |

Manual |

1 set |

|

17 |

CF16 check valve |

Manual |

1 set |

|

18 |

Vacuum pump line |

Stainless steel three direct links and corrugated pipe |

1 set |

|

19 |

Vacuum Gauge |

ZDF5227 |

1 piece |

|

20 |

Permanent magnet target |

Normal target ( compatible with strong magnetic target) |

3 pieces |

|

21 |

Magnetron target connecting pipes assembly |

|

3 pieces |

|

22 |

Baffle of target |

Manual |

3 pieces |

|

23 |

500W RF sputtering power supply |

Full automatic matching |

1 set |

|

24 |

500W DC power supply |

Digital |

1 set |

|

25 |

High quality flow controller |

Rang 0-100SCCM Range 0-20SCCM |

1 channel |

|

26 |

Temperature control power supply system |

|

1 set |

|

27 |

Master control power supply |

Molecular pump, mechanical pump, solenoid valve, hydraulic pressure alarm, illumination barking, substrate rotating, matrix heationg, interlocking control system and so on. |

|

|

28 |

Gas pipe, gas connector pipes |

Mental pipes |

1 set |

|

29 |

Installing rack |

Surface spraying, equipped with trundles and door |

1 set |

|

30 |

Targets |

Test targets |

3 pieces |

The condition of field installation

1. Power supply: 380V 50Hz, 16A air switch

2. Ground: below 3 Ω, diameter of line: 14mm 2 *1

3. The dimension: 700*1040*1400 (width*length*height)

4. Cooling water:

Pressure: 1.5-2kg/cm 2 . The pressure difference between inlet and outlet is above 1kg/cm 2

Flow speed: 25-30L/M filtration soft water

Temperature: 20-22℃

Water quality: filtration soft water

Specification of connectors: 1”PT female end*2

Technical service and Quantity guarantee

1. According ISO9001 to design, manufacture, adjust, test, pack and ship.

2. Offer the manual and direction of outsourcing accessories.

3. Freely maintain the problems caused by normal usage. As for the problems caused by improper, just charge cost of production. Charge cost of production for life maintenance.

Training

1. Training time: one week

People: 2-3

2. Training and requirements

1) Understanding the working principle, constitute and each part’s module of equipment, control system’s

working principle and using method.

2) Familiar with the operation of the whole set

3) Could diagnose general malfunction and maintain. Could change the quick wear part

4) Could maintain the equipment everyday