- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Daswell

-

Weight:

-

3500 kg

-

Capacity::

-

35 m3/h

-

Mixer::

-

JS500 or Sicoma mixer

-

Total power:

-

55kw

-

Control mode::

-

computer controlled

-

Electric Control System::

-

Schneider electrical components

-

Installation::

-

under our engineer's guidance

-

Color::

-

according to your requirement

-

Certification:

-

ISO9001-2008,CE

Quick Details

-

Machine Type:

-

Production line

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Daswell

-

Weight:

-

3500 kg

-

Capacity::

-

35 m3/h

-

Mixer::

-

JS500 or Sicoma mixer

-

Total power:

-

55kw

-

Control mode::

-

computer controlled

-

Electric Control System::

-

Schneider electrical components

-

Installation::

-

under our engineer's guidance

-

Color::

-

according to your requirement

-

Certification:

-

ISO9001-2008,CE

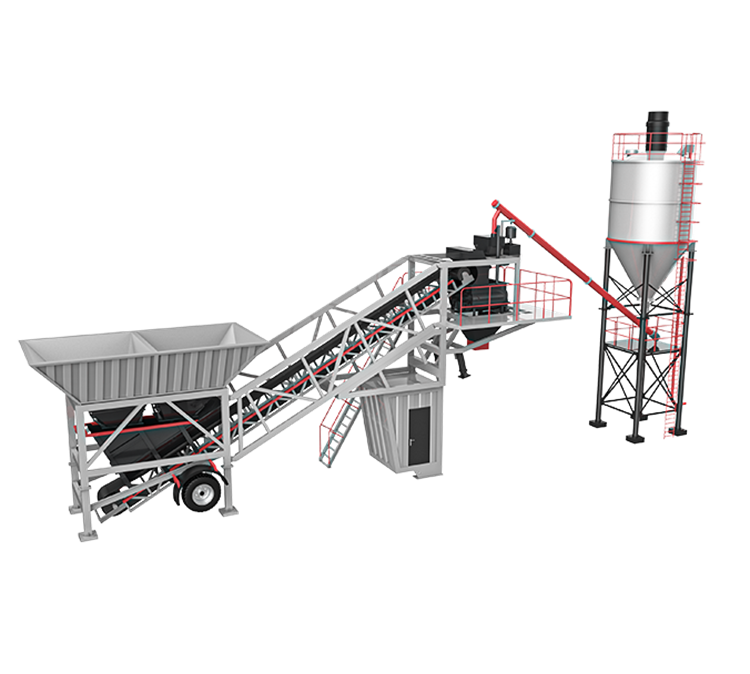

portable mobile concrete batching plant for sale

Introduction of

mobile concrete batching plant:

Introduction of

mobile concrete batching plant:

The concrete mobile batching plant is easy to move and occupies a small area, which is favored by many overseas customers. Daswell Machinery provides mobile batching plants ranging from 25m3/h to 100m3/h. Among them, 25m3/h to 75m3/h need a trailer for transportation. The 100m3/h mobile batching plant requires two trailers for transportation.

|

Model |

MCBP35 |

|

Capacity (m3/h) |

35 |

|

Concrete mixer model |

TCM750 |

|

Mixing power (kw) |

30 |

|

Output per batch of mixer (m3) |

0.75 |

|

Max. Aggregate Size |

≤ 60/80 |

|

Aggregate bin (m3) |

2×8 |

|

Walking speed (km/h) |

20 |

|

Discharge height (m) |

3.8 |

|

Total power (kw) |

55 |

Advantages of mobile concrete batching plant;

Advantages of mobile concrete batching plant;

1. It is easy to move, and the transition is convenient, only one or two trailer heads can be towed away.

2. Compact structure, easy installation and disassembly. Save installation time.

3. Free foundation. No special foundation is required. Customers only need to harden the ground or hit a layer of concrete. Save on foundation costs.

1.Does the mobile batching plant need a foundation?

The mobile batching plant does not need to lay a foundation, only need to harden the ground (except for the cement silo). It is recommended to lay a layer of concrete floor on the ground.

2.There is no bulk cement on site, only bagged cement, what should I do?

Don't worry, we can provide a bag breaking bucket, the bagged cement passes through the bag breaking bucket, and then is transported by a screw conveyor to the cement weighing. If the large-scale mixing plant has a high demand for cement, we can provide a bag breaking bucket + horizontal feeder to send the cement into the cement silo for storage for the mixing plant.

3.How many years can the mixing station last?

A mixing station is not a consumable product. Its main components are the steel frame and some other accessories. With regular maintenance and replacement of wearing parts, it can be used all the time. If the customer's project is only one or two years old, after use, it can be used as a second-hand mixing plant and sold to other customers in need.

4.What should I do if there is a failure during use?

Our after-sales personnel are online 24 hours a day to solve customer's after-sales problems. If it is a software failure, we can solve it by remotely assisting customers. If it is a hardware problem, we usually bring some consumables when shipping. After finding the problem, you can replace the consumables. If there are no spare parts at the fault site, we will arrange the parts immediately during the warranty period and ship them to the customer by air, so as to avoid delaying the use of the customer as much as possible.