- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Fote

-

Dimension(L*W*H):

-

400x300mm

-

Weight:

-

8000 KG

-

Product name:

-

glass crusher machine

-

Max feeding size:

-

350mm

-

Output size:

-

0-25mm

-

Material:

-

Carbon Steel

-

Color:

-

Customer Requirement

-

Wearing parts:

-

Plate Hammer

-

Crusher type:

-

Coal Hammer Crusher

-

Advantage:

-

High Efficiency Low Energy

-

Online Service Time:

-

7*24h

-

Guarantee:

-

one year

Quick Details

-

Application:

-

Stone crushing plant

-

Capacity(t/h):

-

3-95

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fote

-

Dimension(L*W*H):

-

400x300mm

-

Weight:

-

8000 KG

-

Product name:

-

glass crusher machine

-

Max feeding size:

-

350mm

-

Output size:

-

0-25mm

-

Material:

-

Carbon Steel

-

Color:

-

Customer Requirement

-

Wearing parts:

-

Plate Hammer

-

Crusher type:

-

Coal Hammer Crusher

-

Advantage:

-

High Efficiency Low Energy

-

Online Service Time:

-

7*24h

-

Guarantee:

-

one year

Hammer Mill Crusher Excellent choice for crushing and forming

Our hammer mill crusher is commonly known as the PC series. Its simple structure and unique rotary hammer make it easy to operate, handling crushing and forming tasks in a single operation.

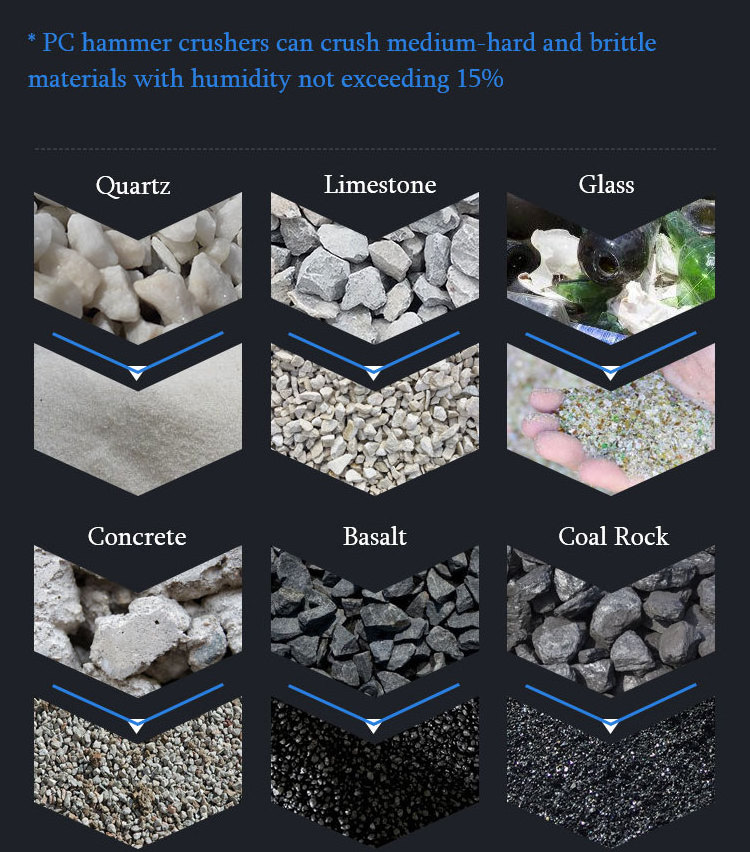

PC hammer crushers can crush medium-hard and brittle materials with humidity not exceeding 15%, such as coal rock, coal gangue, glass, concrete, road rocks, limestone, etc.

Feed size: 600-1,800 mm

Capacity: 3-95 tons/hour

Output size: 25 mm or less

Applications: The final product has complete specifications and is suitable for highway, building and large-scale engineering construction

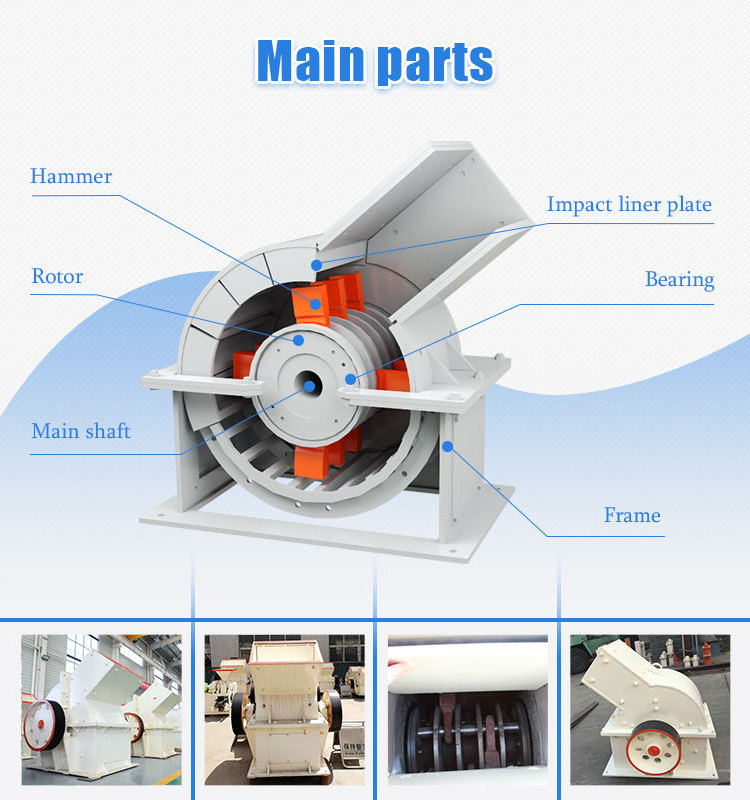

The structure of the hammer crusher

A hammer crusher is mainly composed of frame, rotor, hammer, impact liner plate, bearing, main shaft, and other components. Its main working part is the rotor with hammer.

The unique design and advantages of hammer crushers:

- Large feed size, large crushing ratio (10-50) and high capacity.

- Coarse and medium crushing are completed in one step, simplifying the process.

- Use high chromium iron hammers to extend service life.

- Reasonably designed bearing seat and automatic lubrication enable uninterrupted work.

- The output size is small, uniform, cubic, and less over-crushed.

- The output size is adjustable, with complete specifications of coarse, medium and fine particles.

- Easy to operate and maintain, few wearing parts, low maintenance cost.

- Low power, low energy consumption and good sealing effect.

- Our machine price is 10% lower than the market price.

Working Principle

Hammer mills use impact energy to crush materials. When material enters the crushing cavity, rotating hammers, powered by a motor, strike it and propel it towards an impact plate. The material is hammered repeatedly until it reaches the desired size, then it is discharged through a bottom screen plate. The gap between the impact plate and rotor can be adjusted for specific shape and size requirements.

Check out the video on how hammer mills work

| Specification | Capacity(t/h) | Power (kw) |

| PC 400×300 | 3-10 | 4P 11 |

| PC 600×400 | 6-22 | 4P 22 |

| PC 800×600 | 10-40 | 4P 55 |

| PC 1000×800 | 15-50 | 4P 75 |

| PC 1000×1000 | 18-75 | 4P 90 |

| PC 1200×1200 | 22-95 | 4P 132 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Henan Fote Heavy Machinery Co., Ltd was founded in 1982 in Zhengzhou, Henan, the capital of Chinese machinery manufacturing. The company is large in scale and has four major production bases with a total area of 500,000 square meters, of which standardized heavy industry plants cover an area of 360,000 square meters, providing advanced and reliable infrastructure for production.

Our company focuses on the development and production of mining machinery, including crushers, mills, beneficiation equipment, briquette machines, rotary kilns and other products, which are widely used in mining, chemical industry, construction, coal, ceramics, and other industries. With excellent quality and professional solutions, it has won the trust of customers around the world.

1. We provide customers with a full range of services, including solution design, technical process planning, and the design and manufacturing of standard and non-standard equipment.

2. We dispatch professional technicians to the customer site to assist with shell welding, equipment installation, adjustment, and training of operators.

3. We visit customers regularly to provide lifelong service and technical support.

4. Except for wearing parts, we provide one-year warranty, long-term supply of spare parts, and two-year maintenance of major parts if used correctly.

1. Our equipment holds ISO 9001, CE, and GOST certifications and all equipment undergoes pre-wiring, assembled, and factory tested at our manufacturing facility.

2. We take a test on each machine before delivery.

1. How to get the best price for equipment?

- We are the direct manfacturer, so we can offer you the lowest price than the market price.

- The price of the machine can be given the largest discount based on quantity.

2. Our payment term

- Paypal, T/T, L/C, and Western Union are all available.

- 30% deposit in T/T advance, 70% balance before shipment.

- We take photos of finished products before delivery.

3. Delivery time

- Streamlined production allows for prompt delivery of most products within 6-8 weeks.

- The delivery time will be based on the machine type, selected shipping method, and parts availability.

4. Packaging

- The equipment is wrapped in plastic film before packaging to avoid moisture at sea.

- Bare machines are packed in export containers.

- The motors and small parts are packed in waterproof, sealed, and sturdy wooden cases.

5. Transportation

- Standard container or bulk cargo transportation.

- Sea transportation, air transportation, land transportation, according to customer requirements.

- Complete shipping options and best services at lowest prices are provided: MSC, APL, COSCO, OOCL, CSCL, MSC, MSK, KLINE, etc.

- Seaports in normal use: Qingdao, Tianjin, Shanghai.

- We promise that your goods will be delivered to the destination promptly and safely, and will remind you before the ship arrives.

If you need quality machinery with the latest technology, best prices and fastest delivery, our company is your answer. You are welcome to visit our company and workshop, we sincerely look forward to cooperating with you.