- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

HENGAN

-

Voltage:

-

0

-

Dimension(L*W*H):

-

133*2200mm

-

Marketing Type:

-

New Product 2023, Hot Product 2023

-

Weight (KG):

-

4 kg

-

Product name:

-

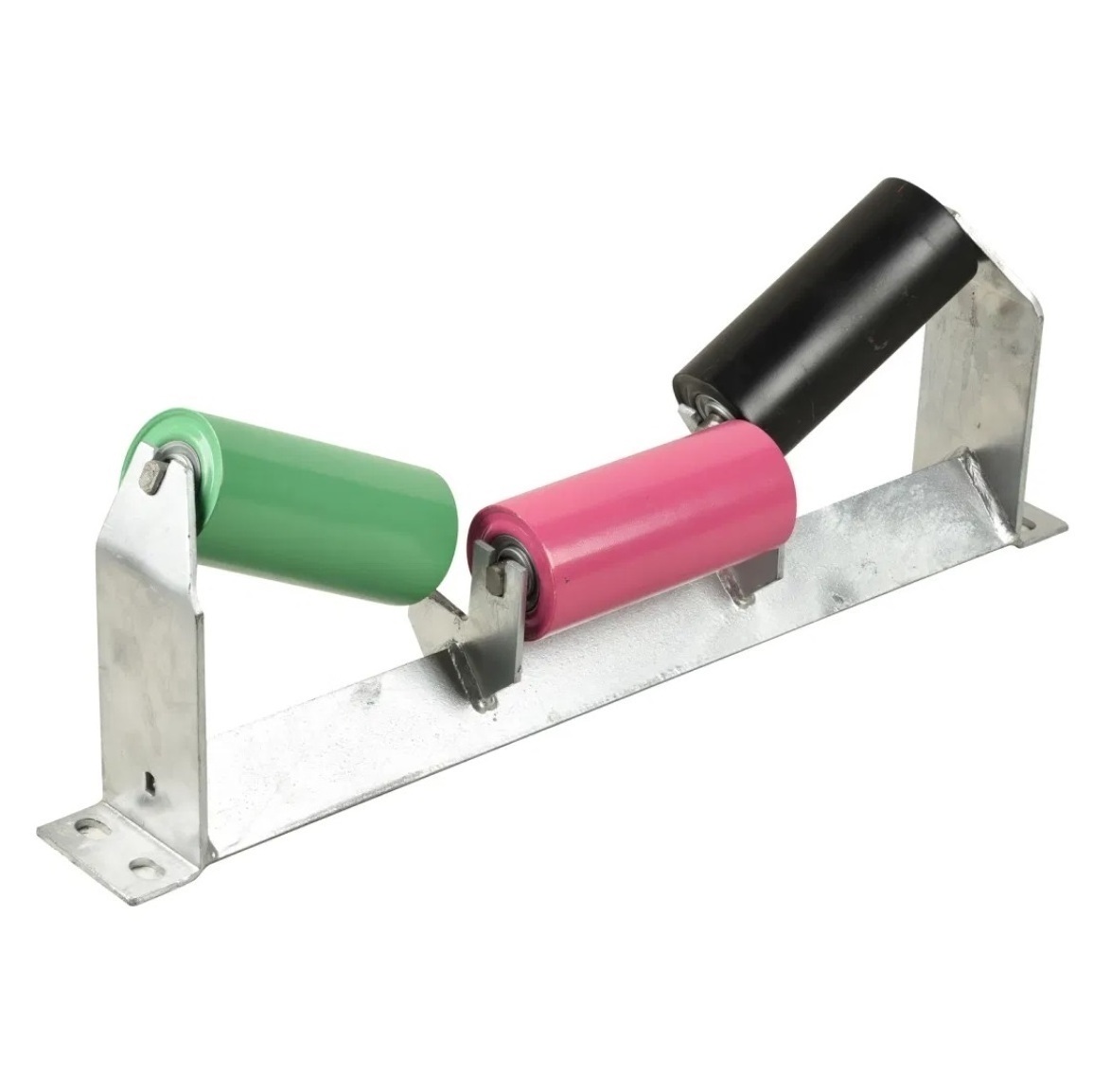

Industrial steel Conveyor rollerSet

-

Application:

-

mining industry

-

Advantage:

-

High Quality Low Cost

-

Function:

-

conveying

-

Certification:

-

CE.ISO,CEMA,ASTM

-

After-sales Service Provided:

-

Overseas Service Provided

-

Color:

-

Customized Color

-

Usage:

-

Industrial Production

Quick Details

-

Power:

-

0

-

Warranty:

-

1 Year

-

Width or Diameter:

-

133mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

HENGAN

-

Voltage:

-

0

-

Dimension(L*W*H):

-

133*2200mm

-

Marketing Type:

-

New Product 2023, Hot Product 2023

-

Weight (KG):

-

4 kg

-

Product name:

-

Industrial steel Conveyor rollerSet

-

Application:

-

mining industry

-

Advantage:

-

High Quality Low Cost

-

Function:

-

conveying

-

Certification:

-

CE.ISO,CEMA,ASTM

-

After-sales Service Provided:

-

Overseas Service Provided

-

Color:

-

Customized Color

-

Usage:

-

Industrial Production

FEATURES AT A GLANCE

The pipe we choose is the high quality welding pipe,the roundness is lower 0.6mm,the straightnesss is 0.15%, the wall thickness tolerance is ±0.1mm, the thickness from 2.5~6.0mm, diameter is from50~219mm0.8,±0.1mm,the thickness from 2.5~6.0mm, diameter is from 50~219mm. The pipe is rust removal to increase paint adhesion.

The shaft we choose is high-precsion rond cold steel,the roundness is 0.8, and the tolerance is only ±0.0065mm, make sure the bearing shaft match closely, the bearing move safely.

This bearing is the joint ventures, it is the roller special double seal, the bearing inner race have V-groove, grease is also the imported grease (Inject the grease into the both sides of the ball bearing).

Bearing housing is punched by the superipr steel sheet(SPHC), After that, we will use the housing circle machine to cut the outside of the housing, to make sure the high Concentricity of the roller and the small runout.

This seal is the national standard double labyrinth seal, 4 pieces pom and 3 pieces stell seal.Injected the high quality No.2 lithium grease. it is water proof and dustproof,anti-corrosion,wear-resisting,ect...

Product Overview

Steel Conveyor Roller

When it comes to material handling, belt conveyors play a crucial role in various industries, enabling efficient and reliable transportation of goods and bulk materials. Different types of belt conveyors are designed to meet specific needs and challenges, offering a range of features and benefits tailored to diverse applications.

HA rollers are designed and manufactured with high quality SPHC tube, bright bar shafts, a choice of fire or water resistant seal arrangements and quality bearings. All rollers are designed and manufactured based on the “sealed-for-life” principle.

HAconveyor are recognized as an eminent manufacturer of quality assured range of steel conveyor roller. Working in close

coordination with our skilled employees, we have been successful in delivering quality assured range of products that are in compliance with the set quality standards. Our quality controllers ensure that only top grade basic components are used in the manufacturing process.

Steel tube rollers are the most common types of idlers that you’ll find on conveyors in the mining industry. All of HAconveyor idlers are designed to meet or exceed the load limits established by CEMA.

If your conveyor is working in demanding applications and needs to conform to CEMA standards, HAconveyor can provide:

Industry leading idler brands with HAconveyor frame workmanship

Idlers and structure that are ideal for harsh mining environments

Idlers that are best for underground conveyor applications

Idlers that utilize the best ball bearing technology

Idlers that have low Total Indicated Runout (TIR)

Idlers that have superior sealing systems

|

Item

|

part

|

statement

|

|

1

|

diameter

|

Φ76, Φ89, Φ102, Φφ108, Φ114, Φ127, Φ133, Φ139, Φ152, Φ159, Φ165, Φ194

|

|

2

|

length

|

145mm-2800mm

|

|

3

|

pipe

|

carbon steel

|

|

4

|

shell

|

Q235(GB), Q345(GB), welded with DIN2394 standed

|

|

5

|

shaft

|

A3 and 45# steel

|

|

6

|

bearing housing

|

SPCC, SPHC

|

|

7

|

bearing

|

6204/6205/6305/6206/6306/6307/6308/6309/6310

|

|

8

|

working hours

|

more than 30000hours

|

Conveyor Roller IDLERS features:

Conveyor Rollers Production Process

Notes:

1. The roller parts, roller skin and bearing seat should be cleaned before welding, and the inside of the roller skin should be

brushed with anti-rust paint, and there is no undercut during welding.

2. When installing, fill up grease in the oil chambers before and after the bearing, and add 1/2 space of lithium-based grease in the sealing groove and the bearing.

3. After the idler roller is installed, under the action of 500N axial pressure, the axial displacement of the roller is not more

than 0.7mm, and when the belt speed is less than 3.15m/s, the beating between the outer diameters of the roller is less than 0.7m.

4. The idler is at 1 After the horizontal and vertical drop test at a height of meters, the roller parts should meet the following requirements: (1) The spoke parts and welds should not be damaged or cracked, and the corresponding joints should not be loosened; (2) The axial displacement of the roller should not exceed 1.5 mm

5. After the installation is completed, it should be ensured that the rotation is dexterous, and the size of the installation is

within the scope of the drawings.

6. Derusting and painting : Remove the rolling oxide rust and foreign matter The processing mating surface should be painted to prevent the oil from being exposed. The non mating surface should be painted with topcoat or primer, and the dry film thickness should be at least 350m.

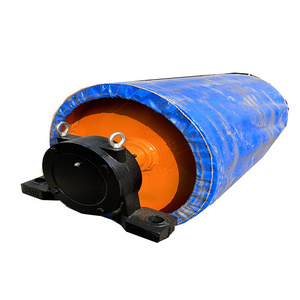

Impact Roller Idlers:

Impact rollers are used as carrying rollers instead of normal steel rollers at a loading point. On steel roller there are rubber rings assembled, side by side, to absorb the weight and impact of material falling onto the belt. At the same time impact rollers reduce the shock and vibration through the steel structure.

Specification of Impact Conveyor Roller Idlers:

|

diameter/mm

|

shaft diameter/mm

|

bearing type

|

Min Bearing Dynamic Loading Pating(N)

|

|

127

|

|

|

|

|

133

|

|

|

|

|

152

|

|

|

|

|

159

|

|

|

|

|

127

|

|

|

|

|

133

|

|

|

|

|

152

|

|

|

|

|

159

|

|

|

|

|

152

|

|

6306

|

28100N

|

|

178

|

|

|

|

|

178

|

35

|

6307

|

33200N

|

|

203

|

|

|

|

|

178

|

|

6308

|

41000N

|

|

203

|

|

|

|

|

203

|

45

|

6309

|

52700N

|

|

203

|

50

|

6310

|

61800N

|

|

250

|

60

|

6312

|

81900N

|

Steel Spiral Return Roller Idler

The steel spiral return idler are used as support for the return side of belt. Used where sticky, corrosive, or abrasive materials are present. Not only cleans itself, but keeps the belt cleans and double spiral configuration minimizes belt training problems such as misalignment.

Specification of steel spiral roller idler:

|

diameter/mm

|

length/mm

|

bearing type

|

shaft diameter/mm

|

|

89

|

950

|

6204

|

20

|

|

108

|

950

|

6205

|

25

|

|

108

|

1150

|

|

|

|

108

|

1400

|

|

|

|

108

|

1600

|

|

|

|

133

|

950

|

6305

|

|

|

133

|

1150

|

|

|

|

133

|

1400

|

|

|

|

133

|

1600

|

|

|

|

159

|

1150

|

6306

|

30

|

|

159

|

1400

|

|

|

|

159

|

1600

|

|

|

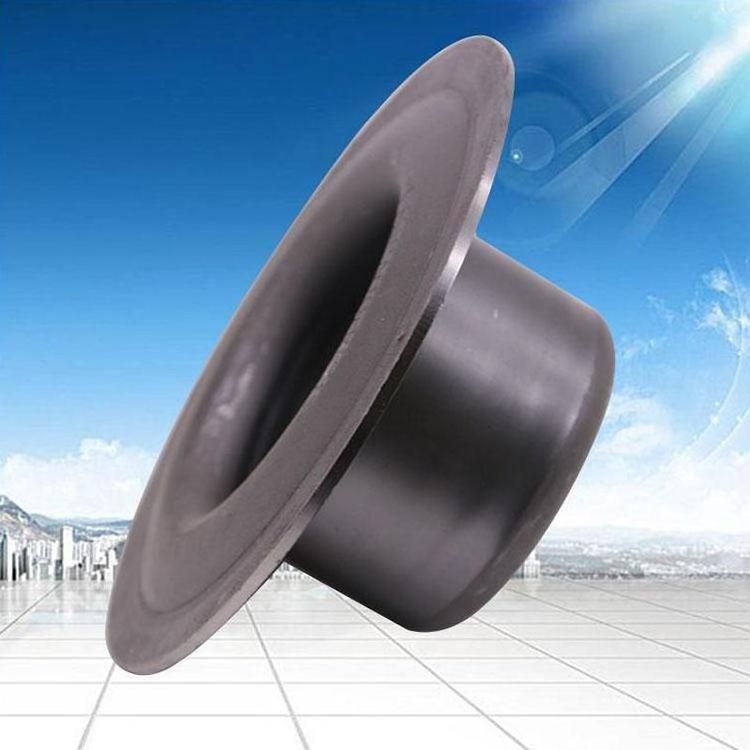

Rubber Disc Return Roller Idler

Disc Return Rollers are used where the material has the potential to collect on the surface of the rollers which could ultimatelylead to premature failure. The Ring minimises material build up on the roller shell. To maximise longevity, routine cleaning should still be observed. Rings come in rubber as standard.

|

pipe/mm

|

ring size/mm

|

|

|

|

|||

|

63.5

|

9mm,108mm,133mm,150mm,180mm,210mm,250mm

|

|

|

|

|||

|

76.1

|

108mm,133mm,159mm

|

|

|

|

|||

|

88.9

|

133mm,150mm,159mm,180mm,270mm,330mm

|

|

|

|

|||

|

108

|

159mm,180mm,195mm,219mm

|

|

|

|

|||

HDPE roller for mining and aggressive applications.

HDPE contains carbon black increasing ultra violet resistance. Steel and HDPE tube combination provides significantly reduced weight. The bearing housing effectively locks the HDPE tube in position preventing movement along the steel tube.

SALES AND SERVICE NETWORK

|

diameter/mm

|

shell wall/mm

|

Nominal Shaft Diameter/mm

|

bearing type

|

Min Bearing Dynamic Load Rating(N)

|

|

127

|

3.5+6.5

|

20

|

6204

|

12700N

|

|

127

|

3.5+6.5

|

|

6205

|

24000N

|

|

152

|

4+6.5

|

|

|

22500N

|

|

159

|

4+10

|

|

|

|

|

127

|

3.5+6.5

|

|

6305

|

|

|

133

|

3.5+9.5

|

|

|

|

|

152

|

4+6.5

|

|

|

|

|

159

|

4+10

|

|

|

|

|

127

|

3.5+6.5

|

|

6306

|

28100N

|

|

133

|

3.5+9.5

|

|

|

|

|

152

|

4+6.5

|

|

|

|

|

159

|

4+10

|

|

|

|

|

178

|

4+6.5

|

|

|

|

|

152

|

6+6.5

|

35

|

6307

|

33200N

|

|

159

|

6+10

|

|

|

|

|

178

|

6+6.5

|

|

|

|

|

152

|

6+6.5

|

|

6308

|

41000N

|

|

159

|

6+10

|

|

|

|

|

178

|

6+6.5

|

|

|

|

|

193

|

6+7.5

|

40

|

|

|

|

219

|

6+13

|

|

|

|

|

178

|

6+7.5

|

|

6309

|

52700N

|

|

193

|

6+7.5

|

|

|

|

|

193

|

6+7.5

|

|

|

|

|

193

|

6+7.5

|

50

|

6310

|

61800N

|

Self Aligning Training Roller Idelers:

The Friction self aligning conveyor roller is used to adjust the belt deviation. Friction friction self-adjusting conveyor roller

has great ability to protect conveyor belt from damage and running offline.

Friction self -aligning conveyor rollers specifications:

|

Diameter(mm)

|

89.7-193.7mm

|

|

|

|

|||

|

Length(mm)

|

500-1400(Total Length:674-1630)

|

|

|

|

|||

|

Shell Thickness(mm)

|

3.2-4.5

|

|

|

|

|||

|

Standard

|

DIN,CEMA,JIS,AS,SANS-SABS,GOST,AFNOR etc.

|

|

|

|

|||

Nylon Rollers and Idlers:

The Nylon Roller Idler is light in weight and easy to install in the air. The nylon wheel has been widely used as a tower crane accessory in various lifting equipment, and gradually replaces the normal metal pulley with its great advantages.

|

shell diameter/mm

|

shaft diameter/mm

|

bearing type

|

material

|

|

89

|

17mm/20mm

|

6204

|

|

|

102

|

20mm/25mm

|

6204/6205

|

|

|

108

|

20mm/25mm

|

6204/6205

|

|

|

114

|

20mm/25mm

|

6204/6205

|

|

|

127

|

20mm/25mm/30mm

|

6204/6025/6206

|

|

|

133

|

20mm/25mm/30mm

|

6204/6025/6206

|

|

|

140

|

20mm/25mm/30mm

|

6205/6305/6206

|

|

|

152

|

25mm/30mm/35mm

|

6305/6206/6306/6207

|

|

|

159

|

30mm/35mm/40mm

|

6306/6207/6308

|

|

|

165

|

35mm/40mm/45mm

|

6206/6306/6207/6308

|

|

All kinds of rollers, idlers, pulleys, rubber belts,belt conveyors can be provided:

FAQ

Q1:How can I know conveyor roller

type and size

is that I need?

A1:Contact our sales, add whatsapp 008618226192162 or email haconveyor@gmail.com for roller detail and your requirement.

Q2 : Can you send samples for checking quality firstly?

A2 : Yes, we can send free samples to you.

Q3 : What trade terms do you support?

A3 : We accept FOB China port, CIF, EXW.

Q4 : What payment terms do you accept?

A4 : We accept transfer by T/T, L/C at sight.

Q5 : What about your delivery time?

A5 : 100 pcs is 10 nature days, more quantity needs discuss in detail.

Hot Searches