- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hoson

-

Voltage:

-

220/380/415/420/440V

-

Power:

-

5.5KW

-

Dimension(L*W*H):

-

20m x 1.1m x 1.4m

-

Weight:

-

5000 kg

-

Product name:

-

Welded Steel Pipe Making Machine

-

Pipe shape:

-

Round Square Rectangle Pipe

-

Keyword:

-

Stainless Steel Pipe Moulding Machine

-

Welding type:

-

High Frequency Welding

-

Thickness:

-

1-4MM

-

Color:

-

Blue

-

Usage:

-

Produce Industrial Steel Pipe

-

Diameter:

-

150-350

-

Capacity:

-

6-50m/min

Quick Details

-

Pipe Material:

-

Stainless steel

-

Marketing Type:

-

New Product

-

Production Capacity:

-

1-1.2Tons/ 8 hours

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hoson

-

Voltage:

-

220/380/415/420/440V

-

Power:

-

5.5KW

-

Dimension(L*W*H):

-

20m x 1.1m x 1.4m

-

Weight:

-

5000 kg

-

Product name:

-

Welded Steel Pipe Making Machine

-

Pipe shape:

-

Round Square Rectangle Pipe

-

Keyword:

-

Stainless Steel Pipe Moulding Machine

-

Welding type:

-

High Frequency Welding

-

Thickness:

-

1-4MM

-

Color:

-

Blue

-

Usage:

-

Produce Industrial Steel Pipe

-

Diameter:

-

150-350

-

Capacity:

-

6-50m/min

Products Description

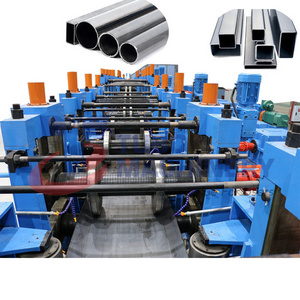

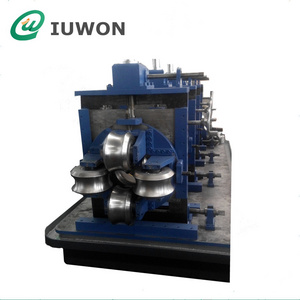

New Style Stainless Steel Welding Pipe Making Machinery Metal Welded Tube Pipe Production Line

Stainless steel pipe mills are mainly used for the production of industrial stainless steel pipes. Due to the maturity of stainless steel welding pipeline technology, seamless pipelines have been replaced in many fields. Widely used in various fields such as chemical, pharmaceutical, brewing, petroleum, food, automotive, papermaking, etc., this pipe rolling machine is newly designed based on actual production and draws on the advantages of domestic and foreign equipment, making it easy to operate and maintain.

DETAIL 1

DETAIL 2

DETAIL 3

Working Process Of Pipe Making Machine :

Raw material (strip steel coil) → uncoiling → shearing and butt welding → material storage → leveling → forming and rolling →high-frequency welding → removing internal and external burrs → zinc supplement → spraying and cooling → sizing and shaping →rough straightening → water removal → sizing and cutting → pipe collection and binding. Fine Structure, Easy Operation,Professional Manufacturing, High Quality.

Raw material (strip steel coil) → uncoiling → shearing and butt welding → material storage → leveling → forming and rolling →high-frequency welding → removing internal and external burrs → zinc supplement → spraying and cooling → sizing and shaping →rough straightening → water removal → sizing and cutting → pipe collection and binding. Fine Structure, Easy Operation,Professional Manufacturing, High Quality.

Product Paramenters

|

Model

|

Pipe Diameter

|

Pipe Thickness

|

Drive Motor

|

Dimension

|

Horizontal shaft diameter

|

Vertical shaft diameter

|

|

HS-40

|

φ8-51mm

|

0.3-2.2mm

|

7.5kw+5.5kw

|

29m*1.5m

|

40mm

|

30mm

|

|

HS-50

|

φ25-76mm

|

0.4-2.5mm

|

7.5kw+5.5kw

|

32m*1.5m

|

50mm

|

30mm

|

|

HS-60

|

φ50-114mm

|

0.5-3.0mm

|

15kw+15kw

|

35m*1.8m

|

60mm

|

30mm

|

|

HS-80

|

φ89-168mm

|

φ89-168mm

|

18.5kw+18.5kw

|

40m*2.5m

|

80mm

|

50mm

|

|

HS-100

|

φ114-219mm

|

φ114-219mm

|

22kw+22kw

|

43m*3.0m

|

100mm

|

60mm

|

|

HS-120

|

φ168-325mm

|

φ168-325mm

|

37kw+37kw

|

48m*3.0m

|

120mm

|

80mm

|

Details Images

Stainless Steel Metal Tube Pipe Making Machine

1. CNC equipment parts processing, high product accuracy;

1. CNC equipment parts processing, high product accuracy;

2. The machine is sturdy and durable, with little chance of maintenance;

3. Adopt Siemens motor and other brand accessories, with high performance;

4. Fully automatic, simple operation, continuous production and high efficiency;

5. The pipe making speed is 15% faster than that of peers, and the output is high;

6. The production cost is low, the material waste is small, and the finished product rate of pipe can reach more than 98%;

7. We have professional designers and planners to customize different solutions for our customers with different requirements, and help them make more reasonable suggestions on production line layout and production management.

8. Provide technical documents and support for mechanical installation, maintenance, operation, etc.

9. Provide machinery related transportation information, be responsible for loading goods and handling transportation related procedures, and pay attention to cargo safety and logistics information at all times.

3. Adopt Siemens motor and other brand accessories, with high performance;

4. Fully automatic, simple operation, continuous production and high efficiency;

5. The pipe making speed is 15% faster than that of peers, and the output is high;

6. The production cost is low, the material waste is small, and the finished product rate of pipe can reach more than 98%;

7. We have professional designers and planners to customize different solutions for our customers with different requirements, and help them make more reasonable suggestions on production line layout and production management.

8. Provide technical documents and support for mechanical installation, maintenance, operation, etc.

9. Provide machinery related transportation information, be responsible for loading goods and handling transportation related procedures, and pay attention to cargo safety and logistics information at all times.

Application Of

New Style Stainless Steel Welding Pipe Making Machinery Metal Welded Tube Pipe Production Line

Pipe making machine is Widely used in various fields such as chemical, pharmaceutical, brewing, petroleum, food, automotive, papermaking, etc., this pipe rolling machine is newly designed based on actual production and draws on the advantages of domestic and foreign equipment, making it easy to operate and maintain.

Packaging & Shipping

Hot Searches