- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZYZG

-

Voltage:

-

440V

-

Dimension(L*W*H):

-

machine size

-

Weight (T):

-

15 T

-

Motor Power (kw):

-

22 kw

-

Warranty:

-

12month

-

Power Source:

-

Hydraulic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

1000 ton hydraulic press

-

Function:

-

meta deep drawing punching stamping

-

Color:

-

Customer

-

Usage:

-

seal head cap making forming

-

Application:

-

Metal Sheet Stamping

-

Keyword:

-

1000 ton Hydryalic Press

-

Material:

-

Steel Material 45#

-

advatage:

-

PLC control

-

Nominal Force (kN):

-

10000 kN

-

Certification:

-

ISO9001 CE

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

900

-

Return Force (kN):

-

2000 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZYZG

-

Voltage:

-

440V

-

Dimension(L*W*H):

-

machine size

-

Weight (T):

-

15 T

-

Motor Power (kw):

-

22 kw

-

Warranty:

-

12month

-

Power Source:

-

Hydraulic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

1000 ton hydraulic press

-

Function:

-

meta deep drawing punching stamping

-

Color:

-

Customer

-

Usage:

-

seal head cap making forming

-

Application:

-

Metal Sheet Stamping

-

Keyword:

-

1000 ton Hydryalic Press

-

Material:

-

Steel Material 45#

-

advatage:

-

PLC control

-

Nominal Force (kN):

-

10000 kN

-

Certification:

-

ISO9001 CE

1000 ton four column hydraulic deep drawing press for metal sheet

1000ton four-column hydraulic press machine is a general-purpose hydraulic press, also known as universal hydraulic press. This series of products is mainly suitable for various stamping processes such as stretching, bending, flanging, punching and cold extrusion of metal materials, and is also suitable for calibration. Press-fit, powder products, press-forming of abrasive products, and press forming of plastic products and insulating materials.

Product features

1.The three-beam four-column structure is economical and practical.

2. The hydraulic control adopts an integrated cartridge valve integrated system, which reduces leakage points, ensures reliable operation and long service life.

3. The machine can realize two molding processes of constant pressure and fixed stroke, and has the function of holding pressure delay, and the delay time is adjustable.

4. The working pressure and stroke can be adjusted within the specified range.

5. It adopts button centralized control and has three operation modes: adjustment, manual and semi-automatic

1000 ton hydraulic press optional accessories

1. Mobile workbench

2. Blanking buffer device;

3 photoelectric protection device;

4. Travel, pressure, speed digital display, numerical control device;

5. Touch industrial display;

6. Hydraulic system heating and cooling device;

7. The feeding device;

8. Slide safety plugs;

9. mold heating and temperature control device;

10. PLC programmable controller.

Product parameters

|

Specification |

Unit |

YQ32-630 |

YQ32-800 |

YQ32-1000 |

YQ32-1250 |

YQ32-1600 |

YQ32-2000 |

|

Nominal force |

Kn |

6300 |

8000 |

10000 |

12500 |

16000 |

20000 |

|

Max pressure of hydraulic system |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max. Opening height |

mm |

1500 |

1800 |

1600 |

1600 |

1800 |

1800 |

|

Slider effective stroke |

mm |

900 |

1000 |

900 |

900 |

1000 |

1000 |

|

Working table size |

mm |

1600*1600 |

1500*1500 |

1500*1500 |

1800*1600 |

1600*1600 |

2000*1800 |

|

Nominal force of Ejection cylinder |

Kn |

1000 |

1000 |

1000 |

1000 |

1600 |

2000 |

|

Ejection stroke |

mm |

300 |

350 |

350 |

350 |

350 |

350 |

|

Slider working speed (empty travel) |

Mm/s |

150 |

150 |

160 |

160 |

160 |

200 |

|

Slider working speed (press) |

Mm/s |

10-22 |

10-20 |

10-20 |

10-20 |

10-20 |

10-20 |

|

Slider working speed (Return stroke) |

Mm/s |

120 |

120 |

140 |

140 |

140 |

180 |

1000tons hydraulic press machine used for:

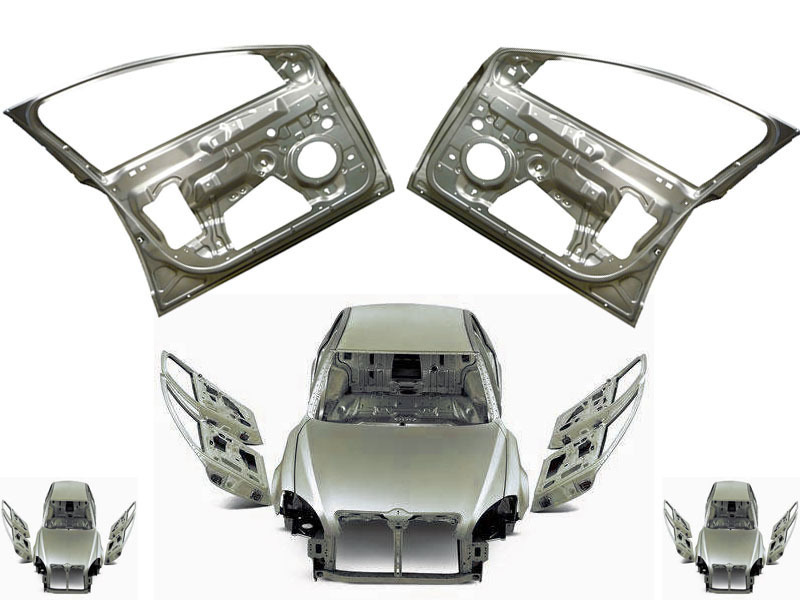

1. Metal Sheet Deep Drawing

Water tank, wheelbarrow, kitchen sink, stainless steel pot, etc

2. Metal/Carton package Stamping

Metal roof tile,washer etc

3. Sheet metal /Aluminum Embossing

Car body, door skin etc

4. Sheet bending and cutting

Packaging Details

Internal plastic moisture-proof anti-rust packaging,

External wooden packaging,

Exclusive container transport.

Delivery Time for High Speed Four Column Hydraulic Press Machine for Oil Filter:

Shipped in 30 days after payment

Pre-sales Service

1. Inquiry and consulting support

2. Sample testing support

3. Recommend the most suitable machine according to customer's purpose

4. Factory visiting welcomed

After-sales Service

1. Training how to install the machine

2. Training how to use the machine

3. Warranty 1 year

4. Engineers available to service machinery oversea