- Product Details

- {{item.text}}

Quick Details

-

Power:

-

75kw

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

22m*2m*4m

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

High Quality Pet Food Production Line

-

Capacity:

-

100---3500kg/h

-

Raw material:

-

Corn powder, rice powder, fish powder etc.

-

Screw material:

-

38#CrMoAl

-

After Warranty Service:

-

Video Technical Support Online

-

Type:

-

Double Screw Extruder Machine

-

Name:

-

Hot Selling Dry Pet Food Production Line

-

Function:

-

Multifunctional

-

Material:

-

Stainless Steel201/304

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHENGRUN

-

Voltage:

-

380V/400V/415V 220V

-

Power:

-

75kw

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

22m*2m*4m

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

High Quality Pet Food Production Line

-

Capacity:

-

100---3500kg/h

-

Raw material:

-

Corn powder, rice powder, fish powder etc.

-

Screw material:

-

38#CrMoAl

-

After Warranty Service:

-

Video Technical Support Online

-

Type:

-

Double Screw Extruder Machine

-

Name:

-

Hot Selling Dry Pet Food Production Line

-

Function:

-

Multifunctional

-

Material:

-

Stainless Steel201/304

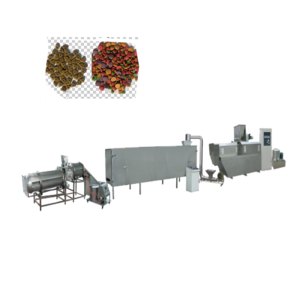

High Quality Pet Food Production Line

Introduction of High Quality Pet Food Production Line

Introduction of High Quality Pet Food Production Line

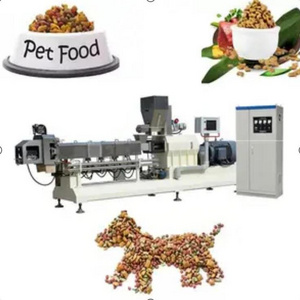

This processing line is specially designed to produce healthy pet food, such as dog food, cat food, ,also fish feed for these animals. Normally using grains powder as main material, mixing with meat, bones powder, fish powder as a flavoring. Pet food machine through adopting pre-conditioning system for raw material, it can increase capacity and reduce power consumption. This line would satisfy different demands for capacity and quality. Producing the many kinds of shape by changing the mould. For this pet food line, we have small capacity and large capacity for your choice.

Samples show

The basic formula of sample

corn meal, wheat flour, wheat bran,rice flour, corn starch, de-oil soya flour, meat, bone, animal oil, vitamins, minerals, food color etc.

Humidity: the moisture is no more than 15%.

Sizes: (1) diameter: from 1.5mm-25mm. (2) length: user-defined.

Process flow: mixing--extruding & puffing-Conveying --Drying--flavoring--Cooling(Packing)

TSE65 Pet Food Production Line( capacity 150kg/h) flow chart

mixer → screw conveyer → TSE65/70 twin-screw extruder → hoister(air conveyer) → 5-layer 5 meter drying oven → single drum flavoring line → cooling machine → packing machine(optional)

TSE90/95 Pet Food Production Line( capacity 800kg/h, 1200kg/h) flow chart

mixer → screw conveyer → TSE85/90/95 twin-screw extruder → hoister(air conveyer) → drying oven → double-drum flavoring line → cooling machine → packing machine(optional)

TSE120/140 Pet Food Production Line( capacity 3000kg/h, 5000kg/h) flow chart

raw materials mixing system → screw conveyer(bucket elevator) → Storage hopper → steam pre-conditioner → TSE9120/TSE140 twin-screw extruder → hoister(air conveyer) → 9-layer 11 meter drying oven (bigger ovens) → double-drum flavoring line → cooling machine → Storage bin → packing machine(optional)

The extruder machinery

The dryer machinery

Technical parameter

| Model | TSE65 | TSE70 | TSE85 | TSE90 | TSE95 | TSE120 | TSE140 |

| Installed power | 74kw | 105kw | 110kw | 132kw | 165kw | 245kw | 290kw |

| Power consumption | 52kw | 75kw | 55kw | 75kw | 90kw | 170kw | 230kw |

| Capacity | 100-150kg/h | 200-250kg/h | 300-500kg/h | 800-1300kg/h | 800-1500kg/h | 2000-4000kg/h | 4000-6000kg/h |

| Dimension | 17*1.3*2.2m | 20*1.5*2.2m | 32*2.0*3.5m | 35*2.5*3.8m |

40*3.5*4.5m |

60*3.0*3.5m |

78*3.0*4.2m |

Features of High Quality Pet Food Production Line

E. For the pet food capacity, we have a small capacity and a large capacity for your reference. You can choose the capacity according to your budget.

F. Customized voltage, we can produce the machines according to your country's voltage, such as 220V, 415V, 400V, etc.

In order to ensure the quality of the machine, the accessories used by the company are mostly domestic or international well-known brands.

Now there are 100 countries people using our equipment including our agents' clients. Not only can our after-sales engineers provide on-site service, but our agents in India, Nigeria, and Peru can also help our customers quickly solve their problems. You can receive professional service.

(1) Free consultation service for all processes;

(2) Free project planning and design services;

(3) Free debugging till every machine running well;

(4) Free delivery management for loading, shipment and transportation;

(5) Free workers training of equipment maintenance and operating;

(6) Free new production techniques and formulas after sales;

(7) 1-year complete warrantee and lifetime maintenance service and cost-price spare parts.