Large bronze shaft casting self lubricating brass graphite bush rubber bushing oiled bronze bushing 90*104*10 mm

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

SUNBEARING

-

Model Number:

-

90*104*10 mm

-

Outer diameter:

-

90.00mm

-

Inner diameter:

-

104.00mm

-

Length:

-

10.00mm

-

Base Material:

-

Brass

-

Coating Material:

-

Graphite/SL4+PTFE+MOS2

-

Name:

-

JDB oilless bearing

-

Standard:

-

DIN1494

-

Feature:

-

Maintenance

-

Application:

-

Machinery

-

Samples:

-

Avaliable

Quick Details

-

Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

-

Type:

-

sleeve

-

Material:

-

Graphite

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

SUNBEARING

-

Model Number:

-

90*104*10 mm

-

Outer diameter:

-

90.00mm

-

Inner diameter:

-

104.00mm

-

Length:

-

10.00mm

-

Base Material:

-

Brass

-

Coating Material:

-

Graphite/SL4+PTFE+MOS2

-

Name:

-

JDB oilless bearing

-

Standard:

-

DIN1494

-

Feature:

-

Maintenance

-

Application:

-

Machinery

-

Samples:

-

Avaliable

Products Description

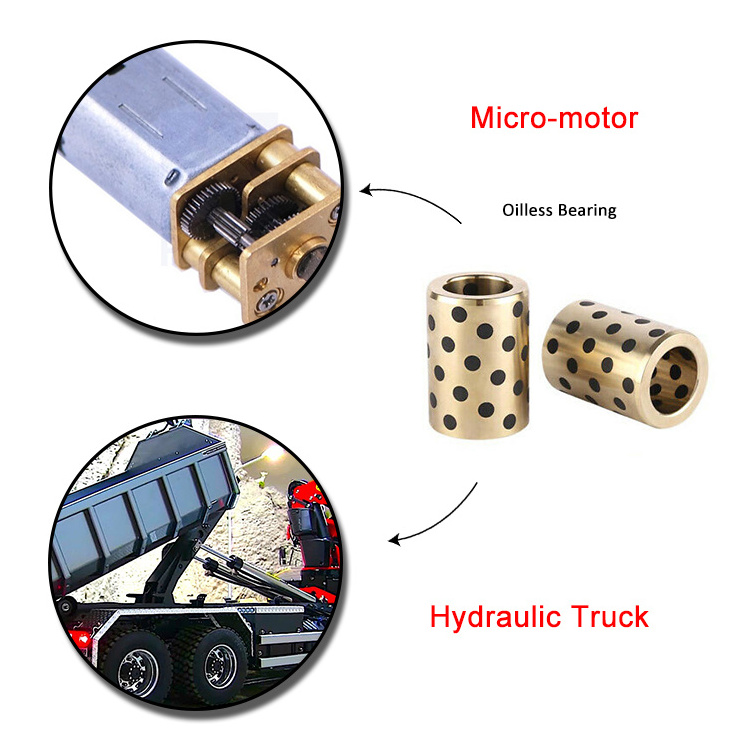

Graphite bearing definition

Oil-free sliding bearings can be self-lubricated by design, work smoothly, reliably and without noise. Under the condition of liquid lubrication, the sliding surface is separated by lubricating oil without direct contact, and the friction loss and surface wear can be greatly reduced. The oil film also has a certain vibration absorption capacity. But the starting friction resistance is large. The part of the shaft supported by the bearing is called the shaft diameter, and the part matching the shaft diameter is called the bearing pad. In order to improve the frictional properties of the bearing pad surface, the layer of anti-friction material cast on its inner surface is called a bearing bush.

|

product name

|

Large bronze shaft casting self lubricating brass graphite bush rubber bushing oiled bronze bushing 90*104*10 mm

|

|

MOQ

|

1

|

|

Sample

|

Avaliable

|

|

number of row

|

single row

|

|

Service

|

OEM Customized Services

|

|

Uses of self-aligning ball bearings

|

Shaft sleeve and pin sleeve for joint parts of construction machinery (excavator, bulldozer, loader)

Water turbine turbine of water conservancy machinery

|

Porous metal material

Porous metal is a powder material that has a porous structure. If it is immersed in lubricating oil, the pores are filled with lubricating oil, and it becomes an oil-bearing bearing with self-lubricating properties. The porous metal material has a low toughness and is only suitable for stable, non-impact loads and medium and small speeds. Bearing plastics: Commonly used bearing plastics include phenolic plastics, nylon, PTFE, etc. Plastic bearings have greater compressive strength and wear resistance, can be lubricated with oil and water, and have self-lubricating properties, but poor thermal conductivity.

Characteristics of graphite bearings

The sliding bearing has the advantages of simple structure, convenient manufacturing, small radial size, strong vibration absorption capacity of the essential oil film, etc. It can withstand a large impact load, so the work is smooth and no noise, and the shaft can be high-speed for a long time under the condition of ensuring liquid friction Operation, suitable for precise, high-speed and heavy-load rotation occasions. Since the required clearance should be obtained between the journal and the bearing to work properly, which affects the improvement of the rotation accuracy; even in the state of liquid lubrication, the sliding resistance friction factor of the lubricating oil is generally still present. Between 0.08-0.12, so its temperature rise is higher, and lubrication and maintenance are more difficult.

Application fields of graphite bearings

1. Shaft sleeve and pin sleeve for joint parts of construction machinery (excavator, bulldozer, loader).

2. Heavy-duty automobile balance shaft bushings.

3. Shock absorber bushes for cars and motorcycles.

4. Hydraulic industry, hydraulic gear pump bushings, oil cylinders, cylinder bushings, etc.

5. Injection molding machine, vulcanizing machine.

6. Mold industry, plastic mold, automobile mold guide sleeve

7. Water turbine turbine of water conservancy machinery.

8. Forging industry, punching machine, etc.

9. Metallurgical industry.

Recommend Products

Details Images

Production processes

During the customer's order production process, we carry out processing inspection, the purpose is to do better quality control

Selection of graphite bearing grease

Oil-free sliding bearings can also be lubricated with grease for better performance. The following points should be considered when choosing grease:

(1) When the bearing load is large and the rotation speed is low, grease with a small cone penetration should be selected, and vice versa. High-speed bearings are selected. Greases with less cone penetration and good mechanical stability are used for oil-free and oil-free sliding bearings. Pay special attention to the lower viscosity of the base oil of the grease.

(2) The dropping point of the selected grease is generally 20-30 ℃ higher than the working temperature. In the case of continuous operation at high temperature, be careful not to exceed the allowable temperature range of the grease.

(3) When oil-free and oil-free sliding bearings work in water or wet environment, calcium-based, aluminum-based or lithium-based grease with good water resistance should be selected.

(4) Use grease with good adhesion

Product packaging

Company Introduction

Sheng Yao Wang (Dalian) International Trade Co., LTD. has been focusing business of bearing production and trade for 17 years, has rich experiences in bearing processing and trade, to provide clients with professional bearing application solutions. The companyprovides the customized products and OEM service. Various new collections and design are coming out each month with the currentstyles and fabrics. The factory own the proficient skill and updated machine

Certifications

our team

Our team attends the exhibition together, meets customers and

our employees took part in the hiking meeting and climbed the mountain to do volunteer photos.

Customer Photos

After customers visited our factory, we invited foreign friends to eat Chinese food, everyone was very happy

Why Choose Us

Diversified advantages of our products and our high quality services

Real comments from customers, we will also listen to suggestions to do better

We are online 24 hours to give you timely responses to solve your needs

Hot Searches