- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380v 12kw

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Wylong

-

Dimension(L*W*H):

-

9*1.9*2.2m

-

Weight:

-

7000 KG

-

model:

-

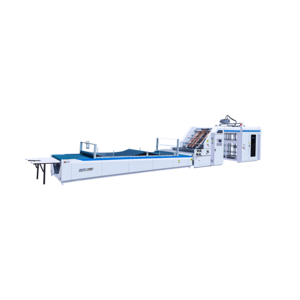

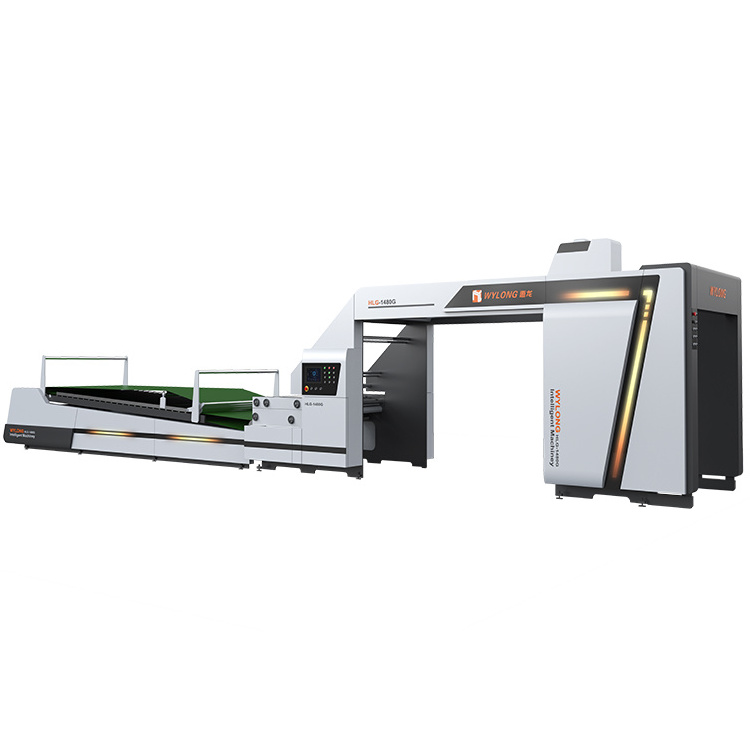

Automatic cardboard laminating machine

-

power:

-

220/380v 12kw

-

thickness of upper paper:

-

120-1000g/㎡

-

thickness of bottom paper:

-

200-1500g/㎡

-

laminate error:

-

±0.5mm

-

operation space:

-

3*12m

-

max speed:

-

100-150pcs/min

-

weight:

-

7000kg

-

dimension:

-

9*1.9*2.2m

-

Brand:

-

Wylong machinery

Quick Details

-

Packaging Type:

-

Cartons, CANS, Bottles, Bags

-

Packaging Material:

-

Paper

-

Driven Type:

-

Electric

-

Voltage:

-

220/380v 12kw

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Wylong

-

Dimension(L*W*H):

-

9*1.9*2.2m

-

Weight:

-

7000 KG

-

model:

-

Automatic cardboard laminating machine

-

power:

-

220/380v 12kw

-

thickness of upper paper:

-

120-1000g/㎡

-

thickness of bottom paper:

-

200-1500g/㎡

-

laminate error:

-

±0.5mm

-

operation space:

-

3*12m

-

max speed:

-

100-150pcs/min

-

weight:

-

7000kg

-

dimension:

-

9*1.9*2.2m

-

Brand:

-

Wylong machinery

Features

1,UP TO 12000 per hour

2,Fully realize intelligent automation

3,Change paper size automatic adjustment machine

4,curve speed positioning ensure accuracy

5,intermittent positioning accuracy of the latest techniligy

6,Automatic tracking system of base paper and surface paper.

7,Correction of the while process of the left and right positioning of the surface paper.

8,interlligent detection of paper length

9,intelligent fault display and ararm system

10,intelligent glue supply and recover system

11,intelligent cleanuing water circulation system

12,base paper bending pressure device

13,bottom paper suction size adjustment device

14,U.S.MAC components open close suction

15,the most advanced electrical control system

16,Servo feeding system for face paper

17,I-shaped pre-pushing system

18,Anti rejection device

19,Surface paper adopts shaftless feida paper paper feeding device

Specification

|

model

|

HLG-1480G

|

HLG-1680G

|

|

|

Max.sheet size

|

1450*1450mm

|

1650*1650mm

|

|

|

Min.sheet size

|

450*350mm

|

450*350mm

|

|

|

Thickness of upper paper

|

150-600g/㎡

|

150-60g/㎡

|

|

|

Thicness of bottom paper

|

Thickness≤10mmA-F corrugated paper,over 300g paper jam

|

|

|

|

Laminate Error

|

±1mm

|

±1mm

|

|

|

Max speed

|

12000pcs/h

|

12000pcs/H

|

|

|

Weight

|

7000kg

|

7000kg

|

|

|

Dimension

|

157000*2200*2600mm

|

161000*2400*2600mm

|

|

|

power

|

22kw/380v

|

26kw/380v

|

|

Electric system brand

|

Name

|

Original

|

Brand

|

|

main motor

|

Taiwan

|

Fukuda

|

|

paper feed motor

|

Taiwan

|

Li Ming

|

|

paper feed motor

|

Taiwan

|

Sanya

|

|

reducer motor

|

Taiwan

|

Fukuda

|

|

red light circle

|

Israel

|

VOLTA

|

|

belt

|

Japan

|

UNIENTI

|

|

reducer

|

shanghai

|

Xinyangda

|

|

vacuum pump

|

Germany

|

Baker

|

|

photoelectric

|

Japan

|

Omron

|

|

relay

|

Germany

|

Schneider

|

|

Touch screen

|

Taiwan

|

Delta

|

|

Inverter

|

Taiwan

|

Delta

|

|

bearing

|

Japan

|

NSK

|

|

drive chain

|

Germany

|

IWIS

|

|

belt tensioner

|

Taiwan

|

Taicang Feiting Transmission

|

|

The electromagnetic valve

|

Japan

|

SMC

|

|

Press button

|

Germany

|

Schneider

|

|

AC contactor

|

Germany

|

Schneider

|

|

PLC

|

Taiwan

|

Delta

|

|

Expansion module

|

Taiwan

|

Delta

|

Machine Structure

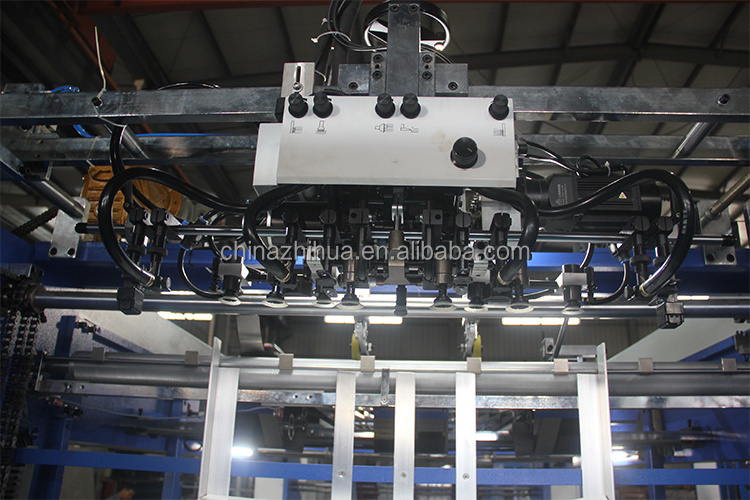

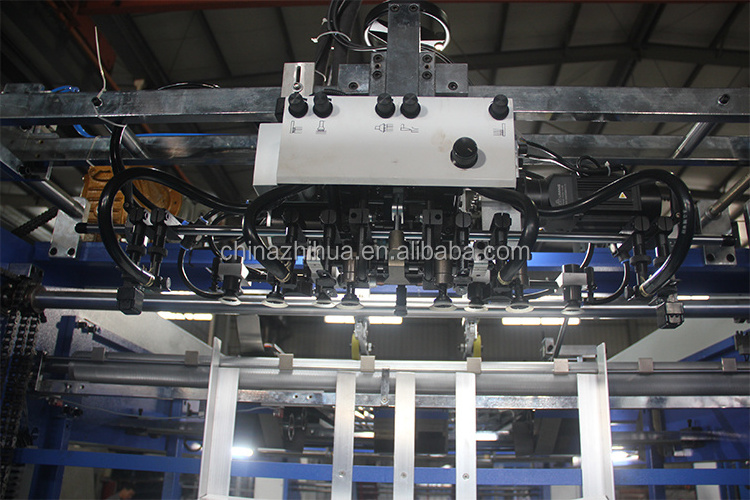

1,Top feeder part

4 suckers for picking up paper and 4 suckers for conveying paper to ensure stable and fast paper feeding.

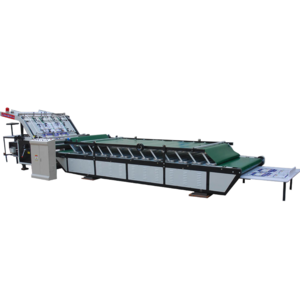

2,Bottom feeding and laminating part

3,Stainless steel material roller ,never rust ,guarentee the amount of glue ies enven

4,Electrical part

Famous brand electridal component ensure machine stability ,high efficiency and low failure.display interface and PLC

combination,display all the information, such as warning, error detect, failures,and operating speed, etc

4. Sheet pressing part

Slope type of the pressing convoyer, humanized design to save effort for the operator collecting the sheets.

Slope type of the pressing convoyer, humanized design to save effort for the operator collecting the sheets.

Certifications

Packing and Delivery

Hot Searches