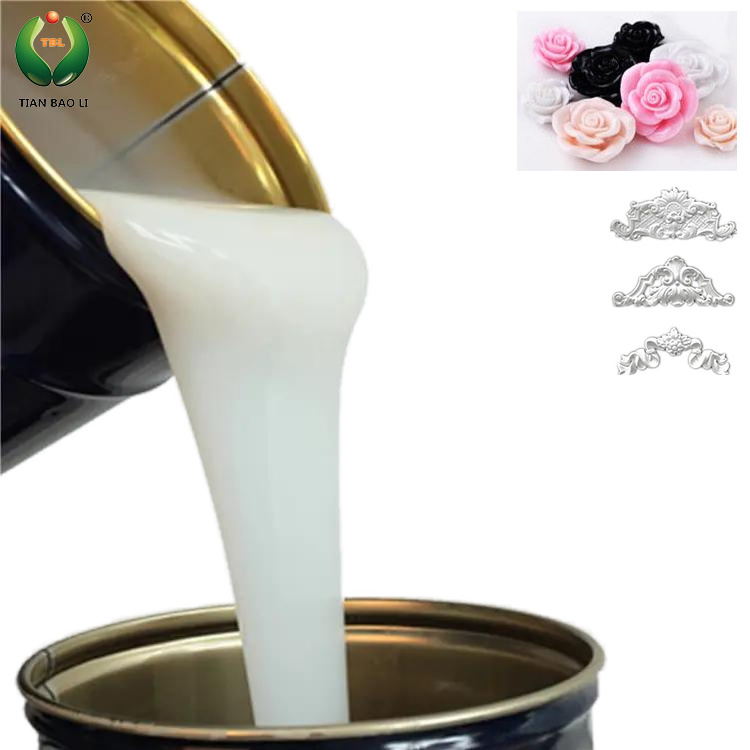

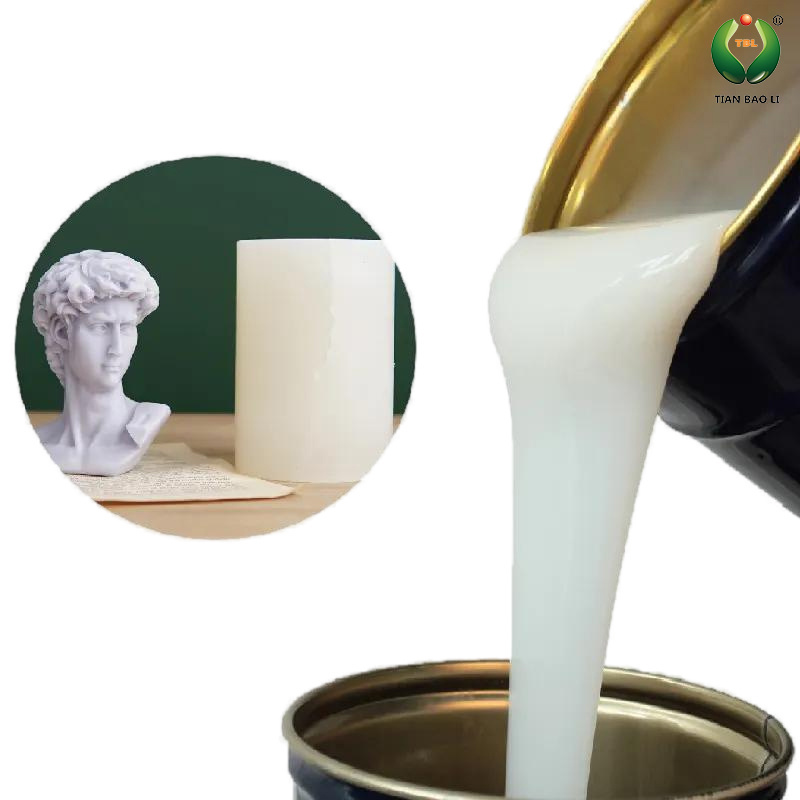

The main products include

HTV silicone rubber (HCR), Liquid silicone rubber (LSR) and RTV silicone sealant.

TBL owns the first and only fully automatic production line for HTV silicone rubber, which is designed and made by the parent company-GMK.

TBL silicone rubber are widely used in various industries such as food contact, medical grade appliance, eclectic & electronic appliance, new energy and automotive, home appliance, industrial filling, LED lighting, etc.

Our products comply with the ISO9001, ISO14001 and IATF 16949:2016 certificates,

formulates to meet requirements of

America food grade, Germany LFGB, EU certificate, UL safety test certificate, ROHS directive and REACH certificate.