- Product Details

- {{item.text}}

Quick Details

-

Structure:

-

bucket elevator

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

king machine

-

Voltage:

-

Local Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

1000 kg

-

Product name:

-

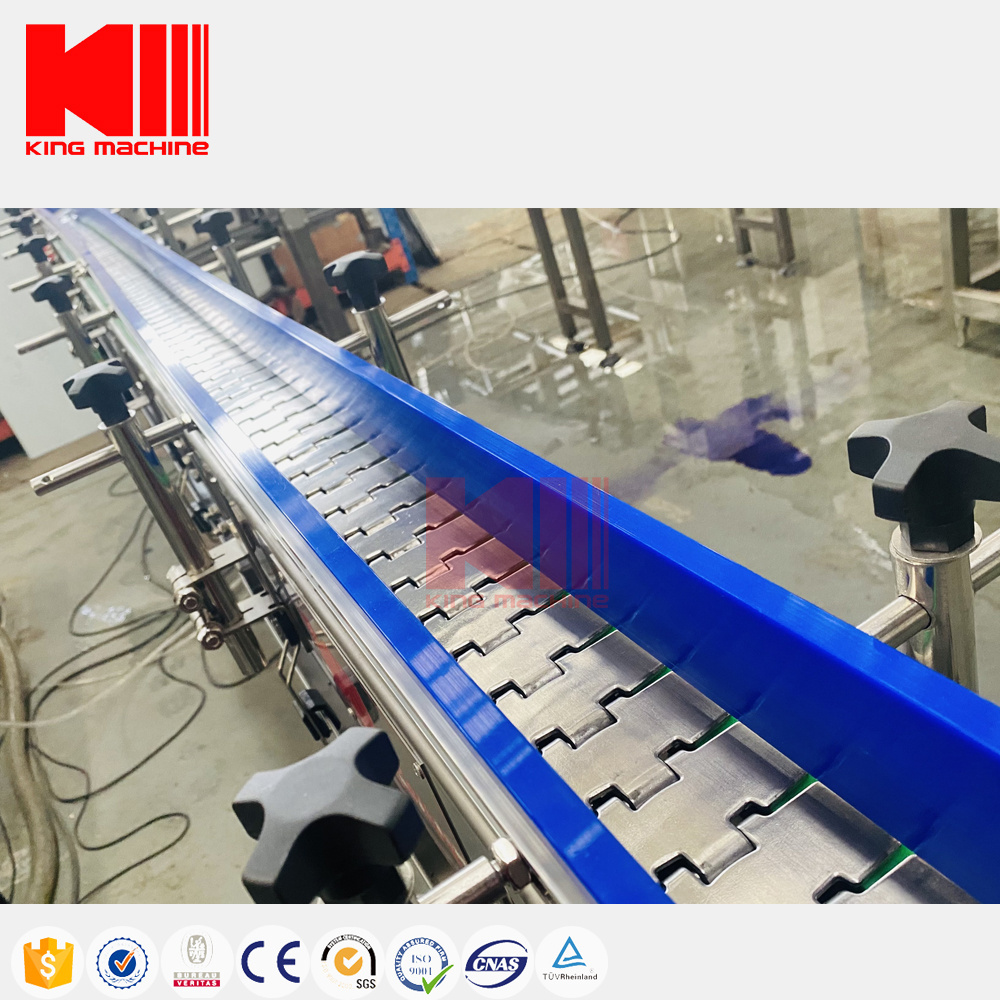

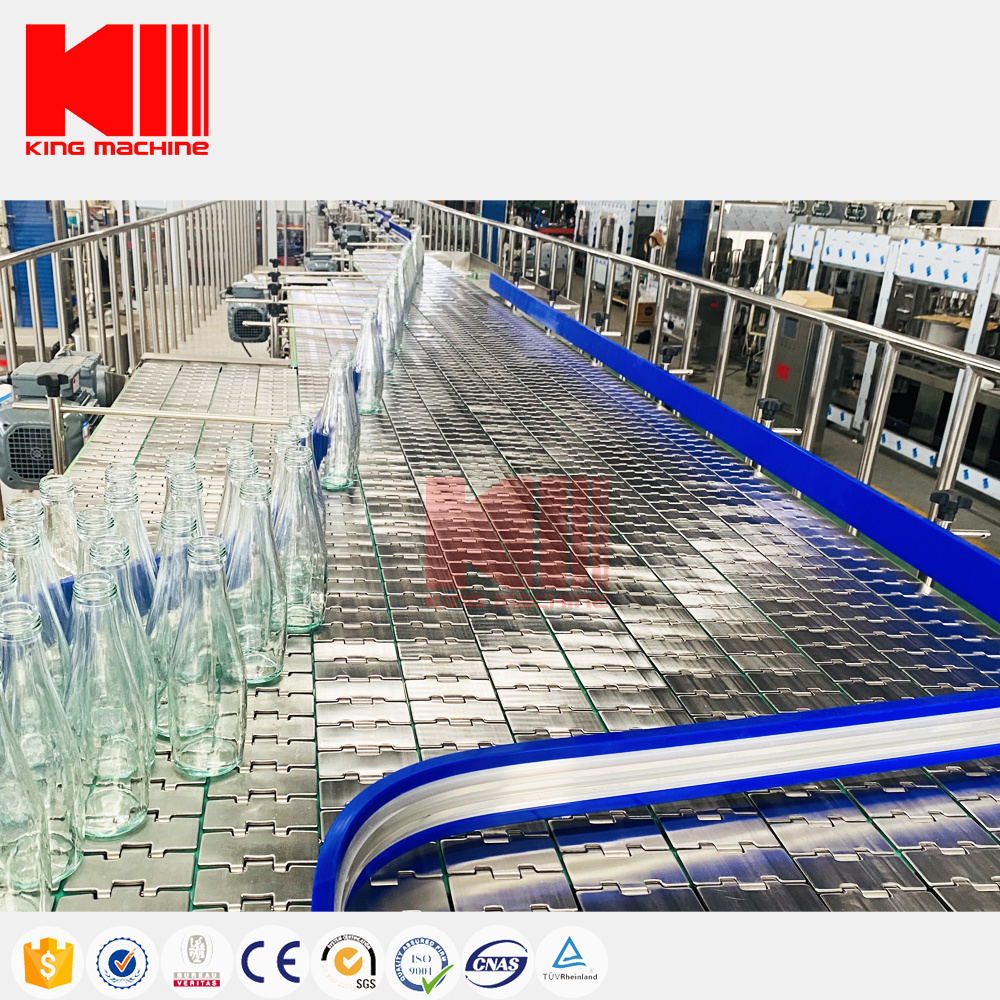

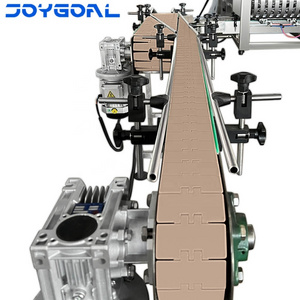

Flat conveyor Stainless Steel Conveyor

-

Color:

-

Request

-

Feature:

-

Variable adjustable speed

-

Application:

-

sugar,beverage

-

Rotating speed:

-

Customer Request

-

Installation:

-

Engineer's Guide

-

Commodity:

-

inclined spiral conveyor

-

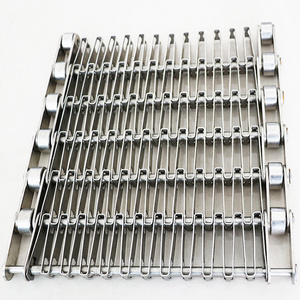

Belt material:

-

PVC PU Rubber/Stainless steel

-

Belt Types:

-

Flat Steel Belts

-

Keywords:

-

Conveyor Belt

Quick Details

-

Power:

-

Customized

-

Warranty:

-

1 Year

-

Width or Diameter:

-

40mm

-

Structure:

-

bucket elevator

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

king machine

-

Voltage:

-

Local Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

1000 kg

-

Product name:

-

Flat conveyor Stainless Steel Conveyor

-

Color:

-

Request

-

Feature:

-

Variable adjustable speed

-

Application:

-

sugar,beverage

-

Rotating speed:

-

Customer Request

-

Installation:

-

Engineer's Guide

-

Commodity:

-

inclined spiral conveyor

-

Belt material:

-

PVC PU Rubber/Stainless steel

-

Belt Types:

-

Flat Steel Belts

-

Keywords:

-

Conveyor Belt

Zhangjiagang King Machine Co.,Ltd

Zhangjiagang King Machine Co., Ltd. is a professional manufacturer of beverage machinery in China.Our main products have: Water filling production line, juice filling production line, carbonated drinks production line, and also aerosol filling machine, 5 Gallon bottle filling production line, and all other auxiliary equipment.

Our engineers are located all over the world and can provide safe and fast service to your beverage production solutions in your country.

Products Description

Stainless Steel Screw Conveyor

The vertical screw conveyor is suitable for conveying powdery, granular, non-viscous dry materials with a bulk density of ≤1.3t/m3, such as grain, oil bran, feed, chemical raw materials, cement, etc., at a vertical or large angle of inclination.The temperature of the material generally cannot exceed 80°C. The vertical screw conveyor is not suitable for conveying blocky and viscous materials.

Stainless Steel

Roller Conveyor

The roller conveyor has a simple structure, high reliability, and convenient use and maintenance. The roller conveyor is suitable for the conveyance of articles with a flat bottom, which is mainly composed of a driving drum, a frame, a bracket, a driving part and the like. It has the characteristics of large transport volume, high speed, light operation, and the ability to realize the transmission of multiple lines at the same time.

Stainless Steel Conveyor

The conveyor belt has good corrosion and abrasion resistance, it can be used both in high and low temperature resistance.

Using high grade stainless steel or carbon steel as raw material, conveyor belt has a long service life span, it's easy to use and maintance.

Flat Conveyor.

- Energy saving. High efficient. Adapt to customer factory layout

- Special lubrication system, keep products clean, health, safety

- Extended service life

- Electric eyes design keep whole line running safety and quickly

- Overload protection mechanism to effectively ensure the safety of the machine

- Special lubrication system, keep products clean, health, safety

- Extended service life

- Electric eyes design keep whole line running safety and quickly

- Overload protection mechanism to effectively ensure the safety of the machine

ABOUT KING MACHINE

About King Machine

1 / Standardized workshop of total 20,000 square meters.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

King Machine Factory

<1> Standardized workshop of total 20000 square meters.

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier&Korea Daewoo, ensure the precision of parts.<2>The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechanical stability.

<3>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<4>Engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier&Korea Daewoo, ensure the precision of parts.<2>The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechanical stability.

<3>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<4>Engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

Certificate &Patent

International certification, National Certificate of equipment verification, and more than 30 invention patents are done in King machine .

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

King Machine Serivce

*7/24 Online Service::Machine running video / Watch our factory online / More service contact us

*Sucessful Beverage Plant::Supply a running beverage line in your country , you can see machine runing directly.

*Installation / Debug / Training:

1 - We will arrange seasoned technician for equipments installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

*After-sales Service:

1 - After checking, we offer 12 months as a quality guarantee, free offer wearing parts and offer other parts at the lowest price.

2 - If you could not solve the problems, we will arrange a technician to your factory solving the problems.

3 - After quality guarantee, we offer technical support and after-sales service.

*Sucessful Beverage Plant::Supply a running beverage line in your country , you can see machine runing directly.

*Installation / Debug / Training:

1 - We will arrange seasoned technician for equipments installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

*After-sales Service:

1 - After checking, we offer 12 months as a quality guarantee, free offer wearing parts and offer other parts at the lowest price.

2 - If you could not solve the problems, we will arrange a technician to your factory solving the problems.

3 - After quality guarantee, we offer technical support and after-sales service.

Customers Feedback

King Machine is a professional manufacturer of beverage machinery in China.With the scientific progressive conception of rapid introduction, we make our machinery cover all over the overseas market. We have been producing our goods with mature techniques and first-class quality. We warmly welcome customers all over the world to visit our manufacture.

Cooperative Customer Brands

FAQ

HOW TO FIND KING MACHINE?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

● Visit exhibition in different countries

● Send King Machine an request and tell your basic inquiry

● King Machine sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to King Machine site

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed& research team,we

can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE KING MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to

ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF KING MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or

instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

● Visit exhibition in different countries

● Send King Machine an request and tell your basic inquiry

● King Machine sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to King Machine site

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed& research team,we

can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE KING MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to

ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF KING MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or

instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

Hot Searches