- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Y81

-

Power (kW):

-

30

-

Weight (KG):

-

5000

-

name:

-

hydraulic scrap metal baler compactors aluminum pressing machine

-

Keyword:

-

aluminum pressing machine

-

Application:

-

Scarp metal baler

-

operational method:

-

PLC or manual operational

-

Dimension of compressed room:

-

1600x1200x800mm

-

Nominal push force:

-

1600KN

-

Production Efficiency:

-

2000-4000kg/h

-

bag coming out:

-

side push

-

Color:

-

Requirement

-

Single Cycle Time:

-

150s

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AUPU

-

Marketing Type:

-

New Product

-

Model Number:

-

Y81

-

Power (kW):

-

30

-

Weight (KG):

-

5000

-

name:

-

hydraulic scrap metal baler compactors aluminum pressing machine

-

Keyword:

-

aluminum pressing machine

-

Application:

-

Scarp metal baler

-

operational method:

-

PLC or manual operational

-

Dimension of compressed room:

-

1600x1200x800mm

-

Nominal push force:

-

1600KN

-

Production Efficiency:

-

2000-4000kg/h

-

bag coming out:

-

side push

-

Color:

-

Requirement

-

Single Cycle Time:

-

150s

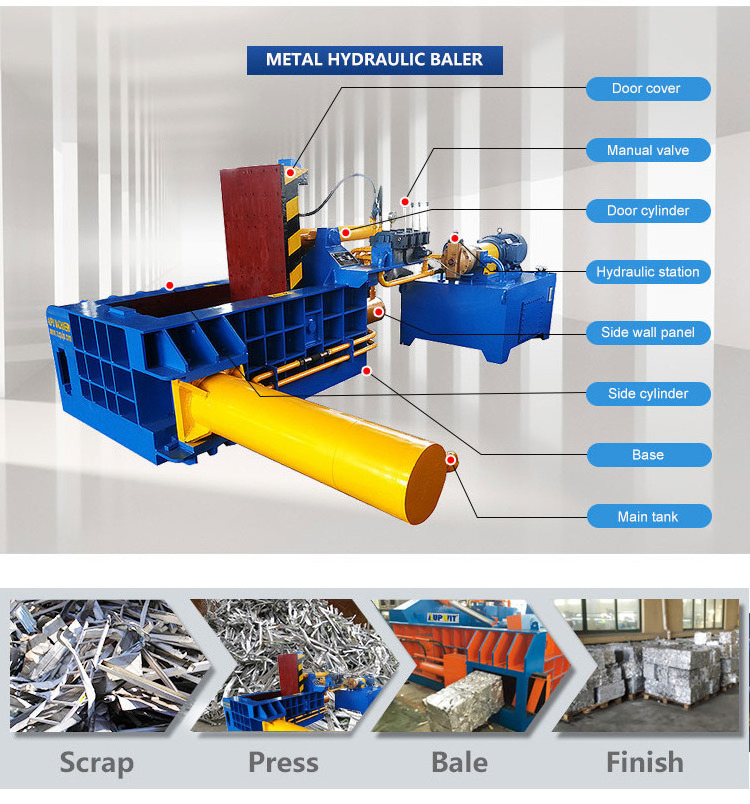

Hydraulic Horizontal Scrap Metal Baler Press Machine

| Type | Nominal push force | Dimension of compressed room | Package block dimension | Production efficiency | Single cycle time | Matched capacity | Bag coming out/ operational method |

| (kn) | (L×W×H)mm | (L×W)mm | (Kg/h) | (s) | (KW) | ||

| Y81T-100 | 1000 | 1000×700×550 | 500×220 | 1200~1500 | ≤85 | 11 | Side push,Manual operation |

| Y81T-125A | 1250 | 1200×700×600 | 600×220 | 1200~1800 | ≤110 | 15 | Side push,Manual operation |

| Y81T-125Y | 1250 | 1200×700×600 | 600×240 | 1200~1700 | ≤115 | 15 | Side push,Manual operation |

| Y81T-135 | 1350 | 1400×900×700 | 600×240 | 1800~2200 | ≤120 | 22 | Side push,Manual operation |

| Y81T-160 | 1600 | 1400×900×800 | 600×300 | 2000~3000 | ≤150 | 22 | Side push,Manual operation |

| Y81T-160A | 1600 | 1600×1000×800 | 700×300 | 2000~3500 | ≤150 | 22 | Side push,Manual operation |

| Y81T-160B | 1600 | 1600×1200×800 | 900×350 | 2000~4000 | ≤150 | 30 | Side push,Manual operation |

| Y81T-200A | 2000 | 1600×1200×800 | 2500~4500 | 2500~4500 | ≤160 | 30,37 | Side push,Manual operation |

| Y81T-200B | 2000 | 1800×1200×900 | 2500~4500 | 3000~5000 | ≤160 | 37,44 | Side push,Manual operation |

| Y81T -- Bale is pushed out of side | |||||||

|

Can be customized for you |

|||||||

Y81 series metal scrap baler is capable of extruding various metal leftover,steel paring,waste copper,aluminum,stainless steel and scrapped car into regular charging as square, column,cylinder etc. different shapes. The costs of transportation and refining can be reduced. It also make the transportation easier and faster.

At AUPWIT Metal Balers, we strive to make scrap metal recycling as effective and efficient as possible. Our balers play an essential role in this and have helped many of our commercial and industrial customers to reduce scrap metal storage and transportation costs. If you would like any information about hiring our mobile baler or our work within scrap metal recycling, please contact us today.

Industrial metal balers are used to improve scrap metal handling, compressing metal into a dense, manageable bale that is easily stackable for better storage. Scrap metal balers are often far more rugged than their plastic or paper counterparts since they need to compress and process tough metal effectively. In addition, many scrap metal baler models are capable of not only baling the metal but also cutting and crushing.

Metal balers can be portable or stationary. Stationary balers are suitable for applications in which the metal that needs baling is already at the site of the baler. However, since the point of metal balers is to compress and make the scrap metal easier to transport, it is often more beneficial to bring the baler to the site where metal is, rather than vice versa.

Non-ferrous metal processing can also take advantage of metal balers. A fantastic example of a non-ferrous metal that benefits immensely from baling is aluminium, a lightweight metal that can take up a lot of space before being compressed.