- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

≥0.05

-

Density (kg/m³ ):

-

128

-

Length:

-

3000/6000

-

Working Temperature:

-

1050C, 1100C/1260C/1360C/1430C (2012F/2300F/2480F/2600F)

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

(1800 ℉, 3h): -3(24h)

-

Thermal Conductivity:

-

0.12-0.20w/m.k(600-800C)

-

Model Number:

-

IK-CF

-

Brand Name:

-

KINGWOOL

-

Place of Origin:

-

Hebei, China

-

Color:

-

White

-

Package:

-

PE and PP bag

-

Application of ceramic fiber blanket:

-

Industrial furnace, electricity boilers, gas turbine and nuclear power

-

Raw material:

-

Ceramic Fibre

-

Package of ceramic fiber blanket:

-

Woven bag or carton

Quick Details

-

Thickness:

-

10-50mm

-

Width:

-

610

-

Chemical Composition:

-

AL2O3, SiO2

-

Ultimate Strength (≥ MPa):

-

≥0.05

-

Density (kg/m³ ):

-

128

-

Length:

-

3000/6000

-

Working Temperature:

-

1050C, 1100C/1260C/1360C/1430C (2012F/2300F/2480F/2600F)

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

(1800 ℉, 3h): -3(24h)

-

Thermal Conductivity:

-

0.12-0.20w/m.k(600-800C)

-

Model Number:

-

IK-CF

-

Brand Name:

-

KINGWOOL

-

Place of Origin:

-

Hebei, China

-

Color:

-

White

-

Package:

-

PE and PP bag

-

Application of ceramic fiber blanket:

-

Industrial furnace, electricity boilers, gas turbine and nuclear power

-

Raw material:

-

Ceramic Fibre

-

Package of ceramic fiber blanket:

-

Woven bag or carton

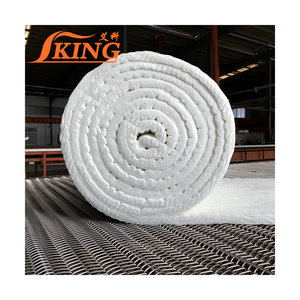

Aluminium silicate heat resistant insulation wool

Product Description:

Ceramic Fiber Blanket is an ideal thermal insulation , fire-proof an d sound-absorbing material. The Ceramic Fiber Blanket is composed of long, flexible, interwoven fibers manufactured by the blown and the spun process yielding a strong, light weight, durable blanket for applications in a temperature range from 1100° C (2012° F ) to 1430° C (2600° F).The ceramic fiber blanket is completely inorganic and is needled to provide exceptional handling strength, u sed in a variety of heat processing applications .

Standard Dimension

Density: 80-128Kg/m3

Length: 3600-14000mm

Width:610mm

Thickness:6-50mm

Product Application:

Ceramic Fiber Blanket is widely used for i ndustrial furnace heat treatment, direct exposure to heat as furnace hot face lining, high temperature filter material, heat treatment insulation, and expansion joints.

Technical Parameters:

| Description | Common | Standard | High Purity | High Alumina | Zirconia | |

| Maximum temperature (°C) | 1000 | 1260 | 1260 | 1360 | 1430 | |

| Working Temperature (°C) | < 1000 | 1050 | 1100 | 1200 | 1350 | |

| Color | white | white | white | white | white | |

| Density (kg/m3) | 96-128 | 96-128 | 96-128 | 128-160 | 128-160 | |

| Shrinkage(%)of heating 24 hours | -4 | -3 | -3 | -3 | -3 | |

| (as density 128 kg/m3) | (1000°C) | (1000°C) | (1100°C) | (1250°C) | (1350°C) | |

| Thermal conductivity (w/m.k)(Density 128 kgs/ m3) | 0.09(400°C) | 0.09(400°C) | 0.09(400°C) | 0.12(600°C) | 0.16(800°C) | |

| 0.16(800°C) | 0.16(800°C) | 0.16(800°C) | 0.20(1000°C) | 0.20(1000°C) | ||

| Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

| (density as 128kg/m3) | ||||||

| Chemical composition(%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

| AL2O3 & SIO2 | 96 | 97 | 99 | - | - | |

| AL2O3 & SIO2 & ZrO2 | - | - | - | 99 | 99 | |

| ZrO2 | - | - | - | 15-17 | 15-17 | |

| Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O & K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

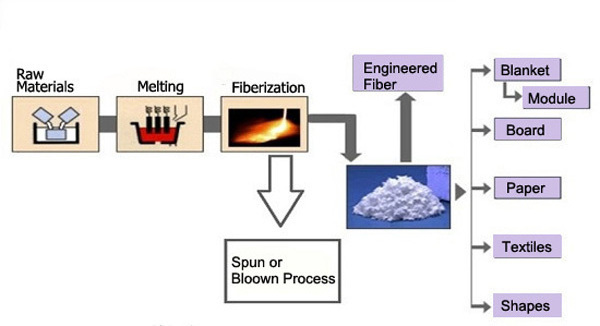

Manufacturing Process:

IKING Ceramic Fiber Blanket Laboratory:

Certifications :

Packing and Shipping:

Welcome to visit our factory any time.