- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM

-

Model Number:

-

JHG

-

Material:

-

Diamond + Metal Powder

-

Tool body:

-

Steel

-

Application:

-

Accuracy single stroke honing

-

Total length:

-

240+

-

Sleeve length:

-

80+

-

Craftmanship:

-

Electroplated or MAS

-

Stone amount:

-

Single pass

-

Certification:

-

ISO9000

-

Mandrel type:

-

Vertical

Quick Details

-

Type:

-

Sharpening Stones

-

Warranty:

-

6 months

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

OEM

-

Model Number:

-

JHG

-

Material:

-

Diamond + Metal Powder

-

Tool body:

-

Steel

-

Application:

-

Accuracy single stroke honing

-

Total length:

-

240+

-

Sleeve length:

-

80+

-

Craftmanship:

-

Electroplated or MAS

-

Stone amount:

-

Single pass

-

Certification:

-

ISO9000

-

Mandrel type:

-

Vertical

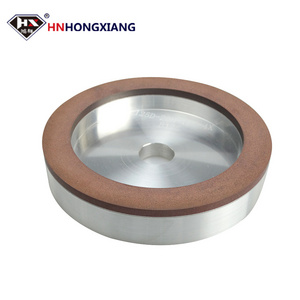

Single pass honing tools with sleeve

The single stroke honing tool is also known as a single pass honing tool that incorporates a super abrasive sleeve mounted on atapered mandrel for precision bore sizing and finishing. Each individual piece of this diamond tool is designed to be matched with corresponding honing machines. According to differences in the bore diameter, customers can choose from our existing models of honing tools, or customize a new honing tool.

The single stroke honing tool works for finishing bores at a minimum of Φ2mm, and is all equipped with thrust pads. In addition,depending on honing and finishing processes, this bore finishing tool come in four types: vertical honing tool, horizontal honing tool, vertical cylinder honing tool, and horizontal cylinder honing tool.

Specific product descriptions are as follows.

We recommend tool:

Mandrel: JHG-6/30.12-160/180

6 pass progress:

The single stroke honing tool works for finishing bores at a minimum of Φ2mm, and is all equipped with thrust pads. In addition,depending on honing and finishing processes, this bore finishing tool come in four types: vertical honing tool, horizontal honing tool, vertical cylinder honing tool, and horizontal cylinder honing tool.

Specific product descriptions are as follows.

Workpiece information:

Final dia after honing 30.12 + 0.01

Before honing dia 30.06

Ra0.4

Through bore

Cast iron

Bore length 180 mm

Hydraulic housing

Vertical machining centre

Low volume production

Final dia after honing 30.12 + 0.01

Before honing dia 30.06

Ra0.4

Through bore

Cast iron

Bore length 180 mm

Hydraulic housing

Vertical machining centre

Low volume production

We recommend tool:

Mandrel: JHG-6/30.12-160/180

6 pass progress:

P1-30.12-D181

P2-30.12-D181

P3-30.12-D151

P4-30.12-D76

P5-30.12-D46

P6-30.12-D25

P2-30.12-D181

P3-30.12-D151

P4-30.12-D76

P5-30.12-D46

P6-30.12-D25

Hot Searches