- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According to the capacity

-

Weight:

-

45000 KG

-

Product name:

-

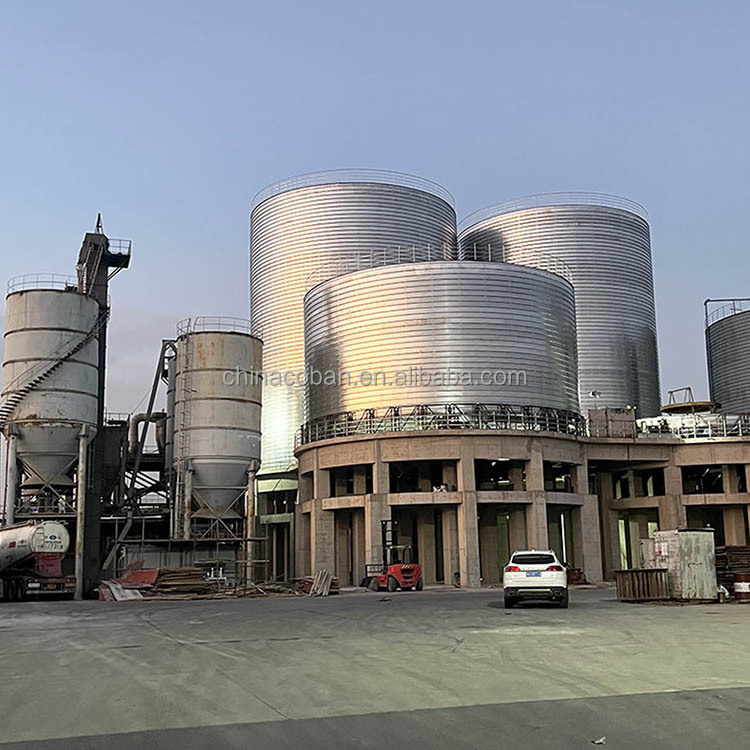

5000-15000 Tons Spiral Steel Silos

-

Application:

-

Cement Fly ash Bulk Powder Storage

-

Capacity:

-

5000-15000 T

-

Coating:

-

Galvanized 275g/m2

-

Safety inspection device:

-

Temperature and moisture monitoring systems

-

Handling equipment:

-

Bucket elevator, drag conveyor, belt conveyor, screw auger.

-

Bottom Type:

-

Flat bottom

-

Discount:

-

Contact to get more discount

-

WhatsApp:

-

+86 19139962050

-

Silo type:

-

Lipp Spiral Storage Silo

Quick Details

-

Core Components:

-

Steel Plate

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

COB

-

Dimension(L*W*H):

-

According to the capacity

-

Weight:

-

45000 KG

-

Product name:

-

5000-15000 Tons Spiral Steel Silos

-

Application:

-

Cement Fly ash Bulk Powder Storage

-

Capacity:

-

5000-15000 T

-

Coating:

-

Galvanized 275g/m2

-

Safety inspection device:

-

Temperature and moisture monitoring systems

-

Handling equipment:

-

Bucket elevator, drag conveyor, belt conveyor, screw auger.

-

Bottom Type:

-

Flat bottom

-

Discount:

-

Contact to get more discount

-

WhatsApp:

-

+86 19139962050

-

Silo type:

-

Lipp Spiral Storage Silo

Product Description

Steel spiral silo with spiral rolled edge process, referred to as spiral steel silo. The spiral steel silo is made by spiraling the steel plate with a certain width into the rolling equipment during construction. Has been widely used in the storage field of grain, food, brewing, feed and other industries.

We mainly provide customized grain steel silo system, Spiral Silo Price/lipp Silo For Bulk Powder Storage, fly ash silo system, grain terminal projects, grain dryer system, rapid & quantitative loading system, grain handling equipment, feed production line etc for customers.

Specification

|

Flat Bottom Steel Silo Technical Specifications

|

|

|

|

|

|

|

|

|

||||||||

|

Capacity(T)

|

1000

|

1500

|

2000

|

2500

|

3000

|

5000

|

8000

|

10000

|

||||||||

|

Φ(m)

|

10.084

|

11.918

|

13.750

|

15.584

|

15.584

|

18.334

|

24.751

|

25.668

|

||||||||

|

Total H.(m)

|

18.69

|

20.34

|

20.87

|

20.3

|

24.78

|

28.6

|

26.99

|

30.6

|

||||||||

|

V(m3)

Density:0.75ton/m³

|

1335

|

2009

|

2701

|

2467

|

4145

|

6693

|

10879

|

13484

|

||||||||

Details Images

Spiral silo construction technology is an advanced steel plate silo construction technology in the world today. Its construction method is unique: during construction, a 495mm wide coil is fed into a forming machine by an uncoiler to form the required geometric shape, and then bent and bitten by a bending machine to form a 30mm-40mm wide, continuous spiral convex strip around the outer side of the silo, which plays a role in strengthening the strength of the silo in structure. For two materials with different materials, the spiral silo construction equipment can also achieve double-layer bending construction.

Unwinding machine:

The material to be processed is placed on the unwinding machine, which unfolds the coil plate.

Forming machine:

Bends the material and preliminarily processes it into shape, while bending the material into the required curvature of the silo diameter.

Bending machine:

Roll the preliminarily formed and matched materials together to form a cylindrical body with a spiral bite.

Support bracket:

A silo that is arranged to support spiral ascent according to the required diameter and circumference of the silo.

High frequency stud welding machine:

The reinforcing ribs are connected to the warehouse wall through studs, changing the destructive effect of ordinary arc welding on the warehouse material.

Roll up:

Lift the silo side sheet to the required height

Recommend Products

Henan Coban Machinery Equipment Co., Ltd. specializes in the production of 100-10,000 ton hopper bottom and flat bottom corrugated galvanized steel silos. According to various factors such as site, weather, and geology, we provide professional silo design, equipped with elevators, unloading pits, pre-cleaner, conveyors, sweeping auger, and other accessories to meet the diverse needs of customers.

Packing & Delivery

Coban’s own installation engineers team plays a respectable role in the success high-performance whole silo system. Our motivated team has rich installation experience for various types of silos, work under a strict and standardized installation management system, has thorough installation cross-checking rules, and promise one-time project acceptance.

Customer site

Coban Grain Feed Silos have passed ISO, CE, and other certifications, attracting customers from all over the world with an efficient sales team and competitive price advantage, we have exported to more than 50 countries, including the United States, Russia, South Korea, Nigeria, Tanzania, Uganda, Colombia, Thailand, Philippines, Zimbabwe, Kenya, and other countries and regions.

Hot Searches