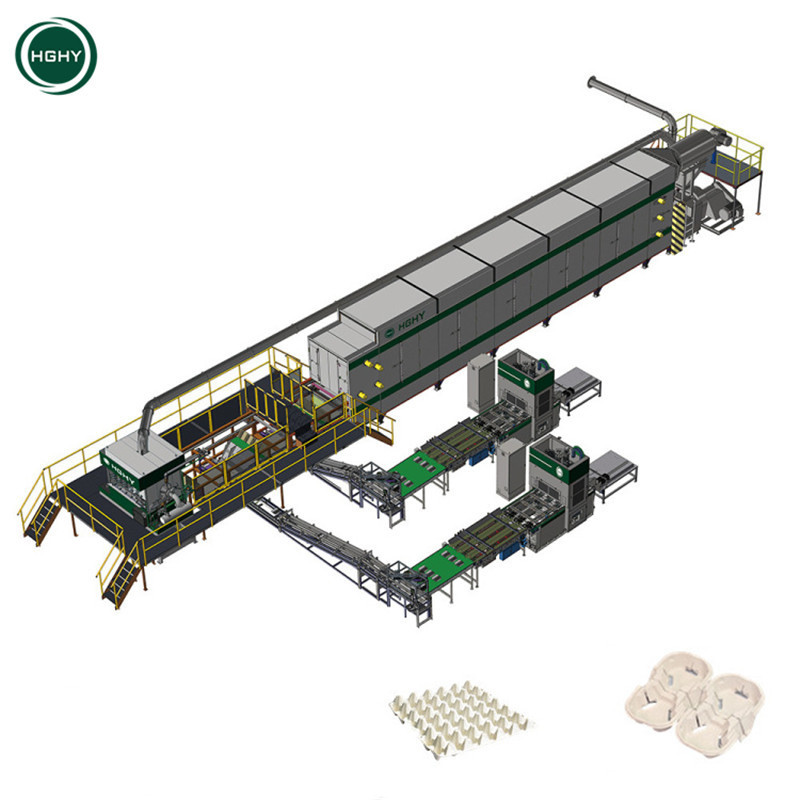

---High performance rotary forming machine, installed over 150 lines.

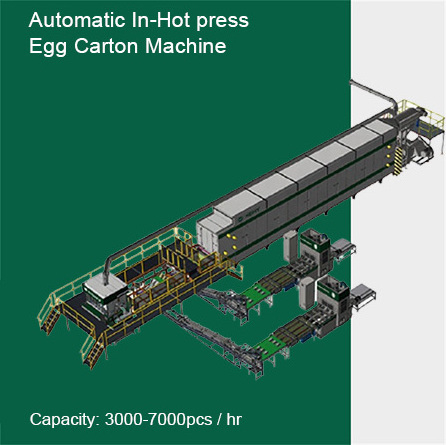

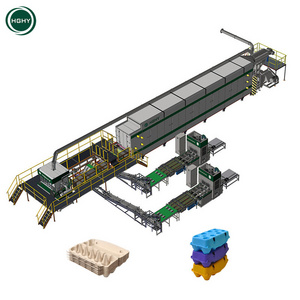

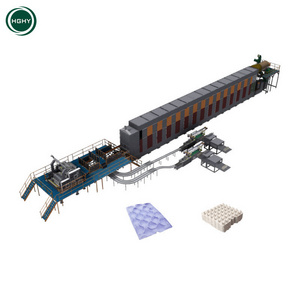

---High efficient 6 layer dryer; Automatic conveying and automatic hot pressing system;

---3rd generation of mature and classical after press.

---High efficient 6 layer dryer; Automatic conveying and automatic hot pressing system;

---3rd generation of mature and classical after press.