- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 380V 440V or Customized

-

Dimension(L*W*H):

-

according to model

-

Power (kW):

-

55

-

Weight:

-

500

-

Screw Speed (rpm):

-

20 - 120 rpm

-

Product name:

-

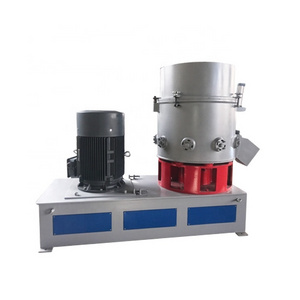

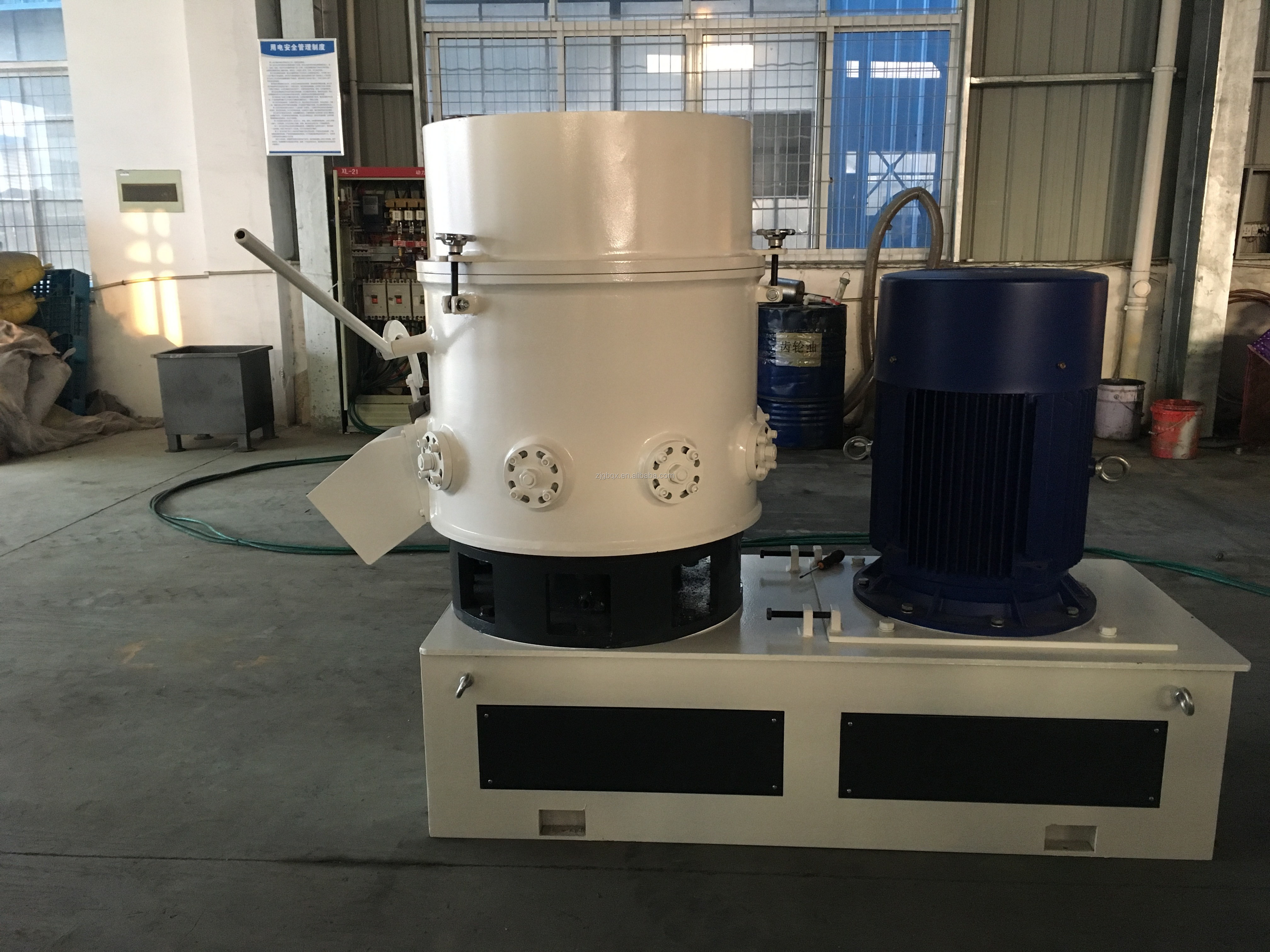

plastic agglomerator machine

-

raw material:

-

PP/PE/PET

-

Motor brand:

-

SIEMENS or customized

-

Bearing brand:

-

HRB or customized

-

Inverter:

-

ABB

-

Temperature:

-

Omron/RKC

-

Contactor:

-

Schneider Brand

-

Heating Method:

-

By self friction

-

Discharge Method:

-

Manually or Pneumatic

-

Rotary blades:

-

2-4pcs

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Output (kg/h):

-

70 - 550 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Polestar

-

Voltage:

-

220V 380V 440V or Customized

-

Dimension(L*W*H):

-

according to model

-

Power (kW):

-

55

-

Weight:

-

500

-

Screw Speed (rpm):

-

20 - 120 rpm

-

Product name:

-

plastic agglomerator machine

-

raw material:

-

PP/PE/PET

-

Motor brand:

-

SIEMENS or customized

-

Bearing brand:

-

HRB or customized

-

Inverter:

-

ABB

-

Temperature:

-

Omron/RKC

-

Contactor:

-

Schneider Brand

-

Heating Method:

-

By self friction

-

Discharge Method:

-

Manually or Pneumatic

-

Rotary blades:

-

2-4pcs

-

Marketing Type:

-

Ordinary Product

Product details:

The plastic agglomerator/densifier machine is used to granulate the thermal plastic films, PET fibers, whose thickness is less than 2 mm into small granules & pellets directly. The soft PVC, LDPE, HDPE, PS, PP, foam PS, PET fibers and other thermoplastics are suitable for it.

Description:

When the waste plastic is supplied into the chamber, it will be cut into smaller chips due to the crushing function of the rotating knife and fixed knife. During the crushing processing, the material that soaked up lots heat from the frictional movement of material being crushing and the wall of container will be going to become semi-plasticizing state. The particles will stick with each other due to the function of plasticization. Before it sticks each other completely, the cold water pre-prepared is sprayed into the material being crushed. The water will be evaporated off quickly and the surface temperature of material being crushed drop down quickly also. So the material being crushed will become small particles or granules. It is easy to recognize the particles by different size and can be colored by using of color agent being putted into the container during the crushing processing.

Main feature:

-Its working theory is different from ordinary extrusion pelletizer, no need electric heating, and can work whenever and wherever possible. It is jointly intelligent controlled by PLC& Computer, easy and stable for operations, and can save more electric power and manpower than common extrusion pelletizer.

2- strong design of double bearing for holding the main shaft,High performance blades,Water flushing automatically.

3-Used for changing PE, PP film/bags into agglomeration granules.Plastic Agglomerator will be recycling a waste of the plastic film and wall thickness of less than 2 millimeters products direct granulation equipment.

|

GSL Series mainly used for PE/PP film, woven bag, non-woven bag, etc.

|

|

|

|

|

|

|

||||||

|

Model

|

GSL100

|

GSL200

|

GSL300

|

GSL500

|

GSL600

|

GSL800

|

||||||

|

Volume (L)

|

100

|

200

|

300

|

500

|

600

|

800

|

||||||

|

Effective volume (L)

|

75

|

150

|

225

|

375

|

450

|

600

|

||||||

|

Rotary blades (Qty)

|

2

|

2

|

2

|

4

|

4

|

4

|

||||||

|

Fixed blades (Qty)

|

6

|

6

|

8

|

8

|

8

|

8

|

||||||

|

Capacity (KG/H)

|

100

|

150

|

200

|

300

|

400

|

550

|

||||||

|

Power (KW)

|

37

|

55

|

75

|

90

|

90-110

|

110

|

||||||

|

GHX Series used for PET fiber to produce popcorn material

|

|

|

|

|

||||

|

Model

|

GHX100

|

GHX300

|

GHX400

|

GHX500

|

||||

|

Volume (L)

|

100

|

300

|

400

|

500

|

||||

|

Effective volume (L)

|

75

|

225

|

340

|

375

|

||||

|

Rotary blades (Qty)

|

2

|

2

|

4

|

4

|

||||

|

Fixed blades (Qty)

|

6

|

8

|

8

|

8

|

||||

|

Capacity (KG/H)

|

100

|

200

|

350

|

500

|

||||

|

Power (KW)

|

37

|

45

|

90

|

110

|

||||

Zhangjiagang Polestar Machinery Co., Ltd. is a hi-tech company, professional in research, developement, production and sales of plastic machines. Polestar is located in Economy Development Zone, Zhangjiagang city, Jiangsu Province(only 120km from Shanghai,60km from Suzhou, and 50km from Wuxi).

For 15 years, Polestar devoted its mind to manufacturing plastic pipe extrusion lines, profile extrusion lines, washing recycling lines, pelletizing production lines, shredders, crushers, mixing units and some other auxiliary equipment. Until now more than 1000 lines are sold to domestic and many customers in the world.

With business principle of 'Quality is foundation and honesty is our first priority', we not only produce high quality machines, but also provide all-round technical support and service.

Polestar looks foward to cooperationg with you and will create a better furture for you!

Packing

:

Wood pallet and cover by plastic film

Service

:

Our Warranty is 1 year for whole machinery.

We will provide the technical advice and find the solution immediately for you when the machine is in trouble.For those wear parts, we guarantee the high quality parts for long-term supply.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Zhangjiagang city, Jiangsu province, When you confirm flight No. and time, please feel free to contact us, then we will pick up you on time.

Q: Why you choose our company?

A:1,Our company have mademachine forabout 20 years with strong experience and advanced technology.

2,we are factory direct sale ,provide you Best Quality and Service with Reasonable price.

Q: What's the trade term and payement term?

A: 30% or 50% T/T before production; Paid in full before shipment.

Q: Will you send the equipment to us directly after completion?

A: After the completion of the equipment,you must first come to the acceptance,confirm that there is no problem before delivery

Q: What price terms you offer?

A: FOB, CIF, EXW and other price terms based on your kind request.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.