Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hanhai

-

Voltage:

-

380V50HZ

-

Dimension(L*W*H):

-

20M*2M*2.5M

-

Power (kW):

-

110

-

Weight:

-

9000 KG

-

Name:

-

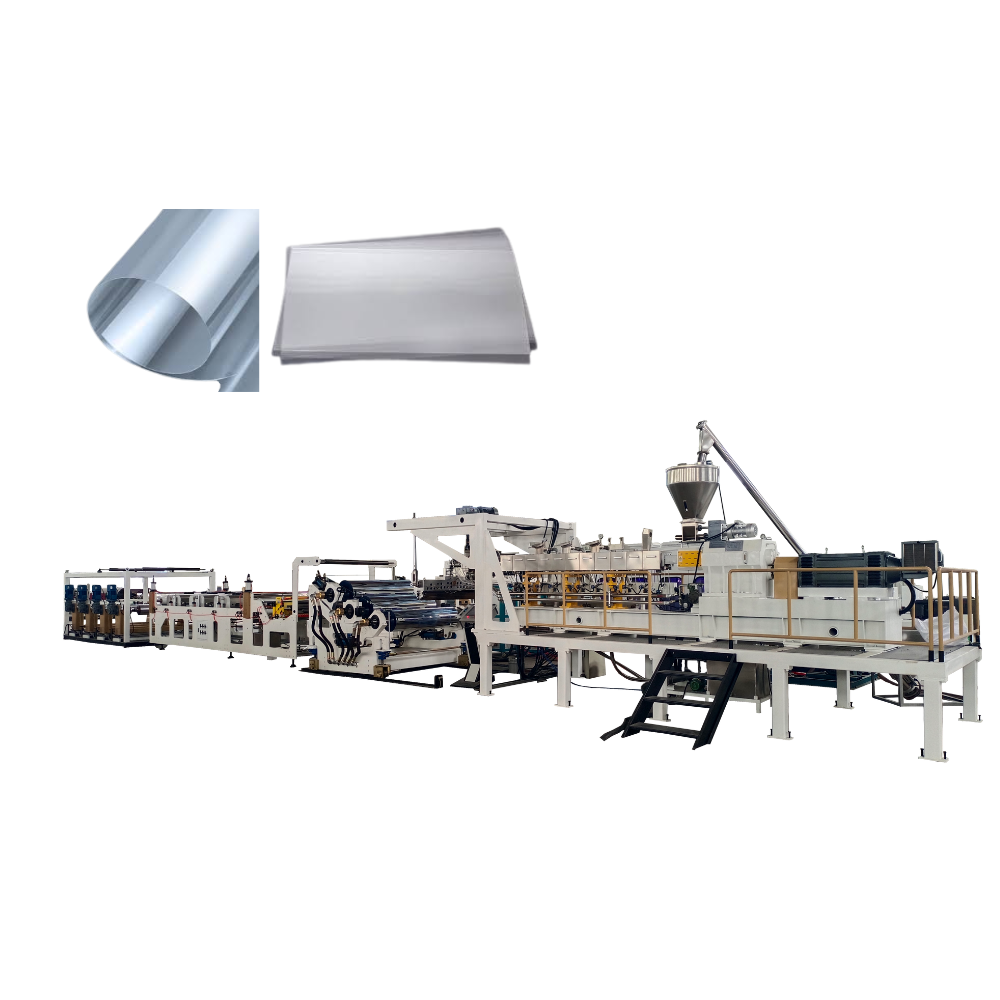

PET Sheet Extruder Making Machine

-

Raw material:

-

PET PP Pellet

-

Inverter:

-

ABB or Delta Brand

-

Feature:

-

Competitive price/Long service life/High-accuracy

-

Cooling way:

-

Recycling Water Cooling

-

Motor:

-

SIEMENS Brand

-

PLC:

-

Siemens

-

Temperature Control:

-

Omron

-

Max output:

-

200-600kg/h

Quick Details

-

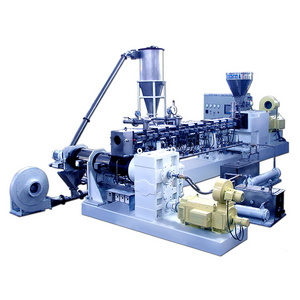

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

39 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hanhai

-

Voltage:

-

380V50HZ

-

Dimension(L*W*H):

-

20M*2M*2.5M

-

Power (kW):

-

110

-

Weight:

-

9000 KG

-

Name:

-

PET Sheet Extruder Making Machine

-

Raw material:

-

PET PP Pellet

-

Inverter:

-

ABB or Delta Brand

-

Feature:

-

Competitive price/Long service life/High-accuracy

-

Cooling way:

-

Recycling Water Cooling

-

Motor:

-

SIEMENS Brand

-

PLC:

-

Siemens

-

Temperature Control:

-

Omron

-

Max output:

-

200-600kg/h

Product Description

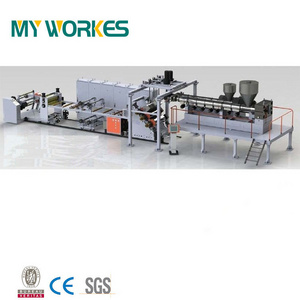

Single Twin Screw Dry Free Vented Clear Thermoforming PET Plastic Sheet Film Extrusion Making Machine Line

1.Characteristic:

highstrength, good heat resistance, good toughness, high surface finish, and easy secondary processing.

2. Main usage:

It is widely used in electric appliance shell,car interior decoration,dinner plate,packing box,cleaning tool,toy,entertainment

facility,instrument,medical appliance and other fields.

facility,instrument,medical appliance and other fields.

3.Process Flow:

Feeder→ Extruder → Mould →three roller calender → Haul-off → Cutter →auto winder

(Note: Other Auxiliary Machine, such as Crystallizer,dryer,crusher, mixer, etc. will be provided according to client's

requirements)

Feeder→ Extruder → Mould →three roller calender → Haul-off → Cutter →auto winder

(Note: Other Auxiliary Machine, such as Crystallizer,dryer,crusher, mixer, etc. will be provided according to client's

requirements)

4.Main List:

|

NO.

|

Name

|

Quantity

|

|

1

|

Parallel screw extruder (with automatic feeding system)

|

1set

|

|

2

|

Hydraulic Screen Changer

|

1 set

|

|

3

|

Die head (Mould)

|

1set

|

|

4

|

Calibrating and cooling tank

|

1set

|

|

5

|

Edge cutting unit

|

1 set

|

|

6

|

Haul-off machine

|

1set

|

|

7

|

Double Station Winding machine

|

1set

|

|

8

|

Bracket

|

1set

|

|

Extruder Modle

|

MAX Products Width

(mm) |

Products Thickness (mm)

|

Production Capacity

(kg/h) |

Total Power

(kw/h) |

|

SJ65

|

600

|

0.3~1.2

|

200

|

120

|

|

SJ90

|

900

|

0.3~1.2

|

250

|

150

|

|

SJ100

|

1200

|

0.3~1.2

|

300

|

180

|

|

SJ120

|

1500

|

0.3~1.2

|

400

|

250

|

Hot Searches