- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

3H,OEM

-

Product name:

-

D Type Rubber Silicone Rubber Profiles Door Rubber Aluminum Seal

-

Material:

-

PVC/EPDM/SILICONE/TPE

-

Certificate:

-

ASTM

-

Business Type:

-

Manufacturer

-

Be suitable for:

-

Window and door seal

-

Production time:

-

3-10 Days

-

MOQ:

-

50kg

-

Payment:

-

T/T or L/C

-

Package:

-

10kg/roll

-

Hardness:

-

50~90 ShoreA

Quick Details

-

Project Solution Capability:

-

graphic design, Cross Categories Consolidation

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

3H,OEM

-

Product name:

-

D Type Rubber Silicone Rubber Profiles Door Rubber Aluminum Seal

-

Material:

-

PVC/EPDM/SILICONE/TPE

-

Certificate:

-

ASTM

-

Business Type:

-

Manufacturer

-

Be suitable for:

-

Window and door seal

-

Production time:

-

3-10 Days

-

MOQ:

-

50kg

-

Payment:

-

T/T or L/C

-

Package:

-

10kg/roll

-

Hardness:

-

50~90 ShoreA

Factory Intoduction

Meirun Rubber & Plastic co., Ltd. was established in Foshan city in 1981. As a wholly-owned subsidiary of Guangdong 3H Group, Meirun rubber & Plastic Co., Ltd. has been developing rubber & plastic business for more than 40 years and has accumulated rich experience in rubber & plastic products production and technology research and development, and is committed to becoming the most competitive and influential rubber & plastic enterprise in China. At present, rubber and plastic products mainly covers the doors and Windows rubber seal products, automotive sealing parts, electrical rubber products in three fields, here only show the application of our gasket products in doors and Windows curtain wall. Special styles and requirements can be customized.

Products and Applications

(1).F

or Out-Swing Casement Windows

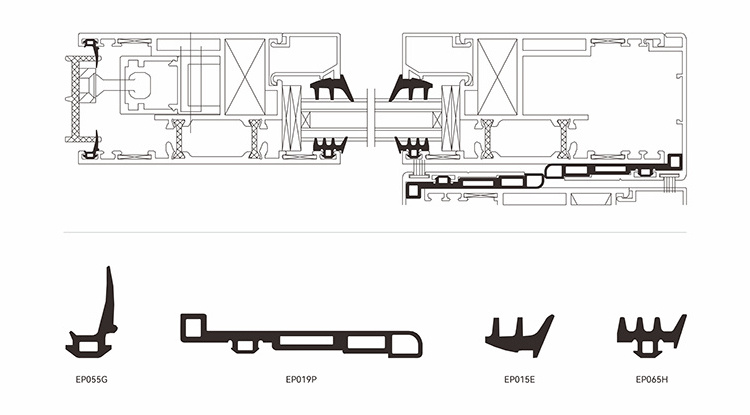

(2).For Lift and Sliding Doors

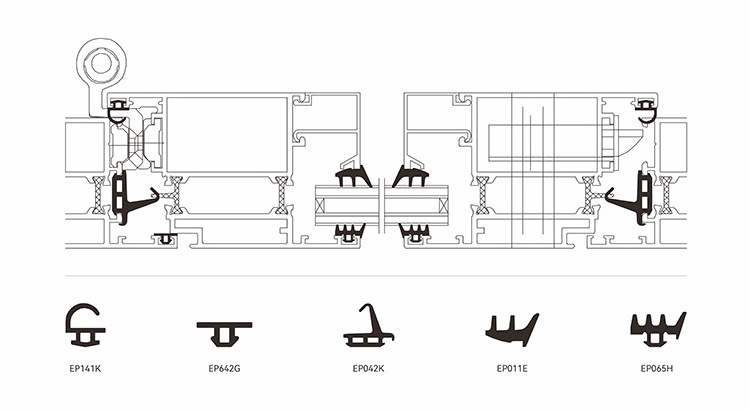

(3).For Double Glazing Doors

(4).for Curtain Wall Windows

(5).

Other Applications

Whole Frame Seal

Corner Seal

Door Window Sealant

Optional Materials and Its Performance Characteristics

Silicone EPDM TPV PVC

|

Applicable temperature range is -100℃~+300℃. It can be used in areas with high temperature, cold, strong ultraviolet radiation and

middle and high-rise buildings.

|

Applicable temperature range is -60℃~+150℃. It can be used in high temperature, cold, coastal areas, areas with strong ultraviolet

radiation, and medium and high-rise buildings. With its wide application range and excellent comprehensive performance, it has

been recognized by the door and window industry at home and abroad.

|

The temperature range of TPV is -40℃~+120℃. It can be applied to cold, as well as medium and high-rise buildings.Its hardness is

about 55-85A,which fully meet customers' demands.Moreover,it has an excellent resilience and compression morphotropy,its environmental resistance nad aging resistance are the same with EPDM. |

The temperature range of PVC is -30℃~+90℃. The shock resistance and elongation at break are both better,and the cost performance

is very good. |

|

Sealing Rubber Strip Specification

|

|

|

|

|

|

|

||||||

|

|

|

SLICONE RUBBER

|

EPDM

|

EPDM Sponge

|

TPV (Thermoplastic Elastomer)

|

PVC

|

||||||

|

B

a

s

i

c

C

h

a

r

a

c

t

e

r

i

s

t

i

c

s

|

Shore A Hardness

|

60±5,65±5

|

70±5,60±5

|

20±5,30±5

|

55±5,70±5,80±5

|

65±5,70±5,75±5,80±5

|

||||||

|

|

Tensile-strength (Mpa)

|

≥5.0

|

≥5.0

|

≥5.0

|

≥5.0

|

≥5.0

|

||||||

|

|

Tensile elongation (%)

|

≥250

|

≥250

|

≥250

|

≥250

|

≥250

|

||||||

|

|

Compression Set (100℃*22h)(%)

|

≤35

|

≤35

|

≤35

|

——

|

——

|

||||||

|

|

Heat Aging(100℃*72h) (Tensile-strength and Tensile Elongation Variation (%))

|

——

|

——

|

——

|

<15,<30

|

<15,<30

|

||||||

|

|

Heat Aging(100℃*168h) (Tensile-strength and Tensile Elongation Variation(%) )

|

<25,<40

|

<25,<40

|

<25,<40

|

——

|

——

|

||||||

|

|

Weight Loss on Heating(%)

|

≤3.0

|

≤3.0

|

≤3.0

|

≤3.0

|

≤3.0

|

||||||

|

|

Low Temperature Brittleness(-20℃)

|

——

|

——

|

——

|

Pass

|

Pass

|

||||||

|

|

Low Temperature Brittleness(-40℃)

|

Pass

|

Pass

|

Pass

|

——

|

——

|

||||||

|

P

e

r

f

o

r

m

a

n

c

e

|

Usage Temperature(℃)

|

-60℃~200℃

|

-50℃~120℃

|

-50℃~120℃

|

-50℃~120℃

|

-20℃~100℃

|

||||||

|

|

Flame Retardant

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

||||||

|

|

Ozone Proof

|

Excellant

|

Excellant

|

Excellant

|

Good

|

Normal

|

||||||

|

|

Storage Life(Year)

|

10-15

|

10-15

|

10-15

|

10-15

|

5-7

|

||||||

|

T

e

c

h

n

i

c

s

|

Forming Method

|

Microwave Vulcanization

|

Microwave Vulcanization

|

Microwave Vulcanization

|

Extrusion Molding

|

Extrusion Molding

|

||||||

|

|

Corner Joint Menthods

|

Vulcanized

|

Vulcanized

|

Vulcanized

|

Heat Weld

|

Heat Weld

|

||||||

|

|

Color

|

Multi-color

|

Black

|

Black

|

Multi-color

|

Multi-color

|

||||||

Certificates

Our company has passed the TUV IATF 16949:2016 and ISO 9001:2015 certification,and the rubber seal products are also passed the European standards and American standards,thus,the quality can be guaranteed.With the good performance of good elasticity and tactility,non-toxic,low carbon,which fully meet customers' requirements.

Other Countries Popular Shapes

Sample Projects

Our network covers more than 30 provinces and regions across the country, and is exported to more than 100 countries and regions such as Southeast Asia, the Middle East, Russia, Australia and Africa.Thus,we have local landmark buidlings applied the EPDM,silicone rubber seals.

FAQ

1.

Does the engineering order have a warranty period? Warranty quantity?

Yes,the rubber strip is divided into different materials, PVC is about 2-3 years, EPDM, TPV, and silicone are more than 10 years.

2. How long does the rubber seal take to open the mold?

About seven days,sample can be provided.

3. Is the rubber seal fire-resistant?

Yes,we can provide the flame resistance test report.

4. What’s the production time for door rubber seal?

The production time of rubber strip is 10 days.

5. How can you guarantee the quality?

Experienced team of engineers and strict quality control. If you meet with quality problem, we promise to replace goods or return your funds.

Yes,the rubber strip is divided into different materials, PVC is about 2-3 years, EPDM, TPV, and silicone are more than 10 years.

2. How long does the rubber seal take to open the mold?

About seven days,sample can be provided.

3. Is the rubber seal fire-resistant?

Yes,we can provide the flame resistance test report.

4. What’s the production time for door rubber seal?

The production time of rubber strip is 10 days.

5. How can you guarantee the quality?

Experienced team of engineers and strict quality control. If you meet with quality problem, we promise to replace goods or return your funds.

Hot Searches