- Product Details

- {{item.text}}

Quick Details

-

Cutting Capacity (mm):

-

330

-

Blade Speed (m/min):

-

80

-

Weight (KG):

-

1000

-

Motor Power (kw):

-

2.2

-

Hydraulic Motor Power (kW):

-

0.42

-

Product name:

-

Horizontal Band Saw Machine

-

Application:

-

Industrial Metal Cutting

-

Keyword:

-

Saw Cutting

-

Cutting material:

-

Metal .alloy Metal .aluminum

-

Function:

-

Cutting Metal Bar

-

Cutting mode:

-

Saw Blade Cutting

-

Model:

-

GZ4230 G330

-

Type:

-

Horizontal Bandsaw

-

Color:

-

Customer`s Requirement

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

REBOUND CNC

-

Marketing Type:

-

Hot Product

-

Cutting Capacity (mm):

-

330

-

Blade Speed (m/min):

-

80

-

Weight (KG):

-

1000

-

Motor Power (kw):

-

2.2

-

Hydraulic Motor Power (kW):

-

0.42

-

Product name:

-

Horizontal Band Saw Machine

-

Application:

-

Industrial Metal Cutting

-

Keyword:

-

Saw Cutting

-

Cutting material:

-

Metal .alloy Metal .aluminum

-

Function:

-

Cutting Metal Bar

-

Cutting mode:

-

Saw Blade Cutting

-

Model:

-

GZ4230 G330

-

Type:

-

Horizontal Bandsaw

-

Color:

-

Customer`s Requirement

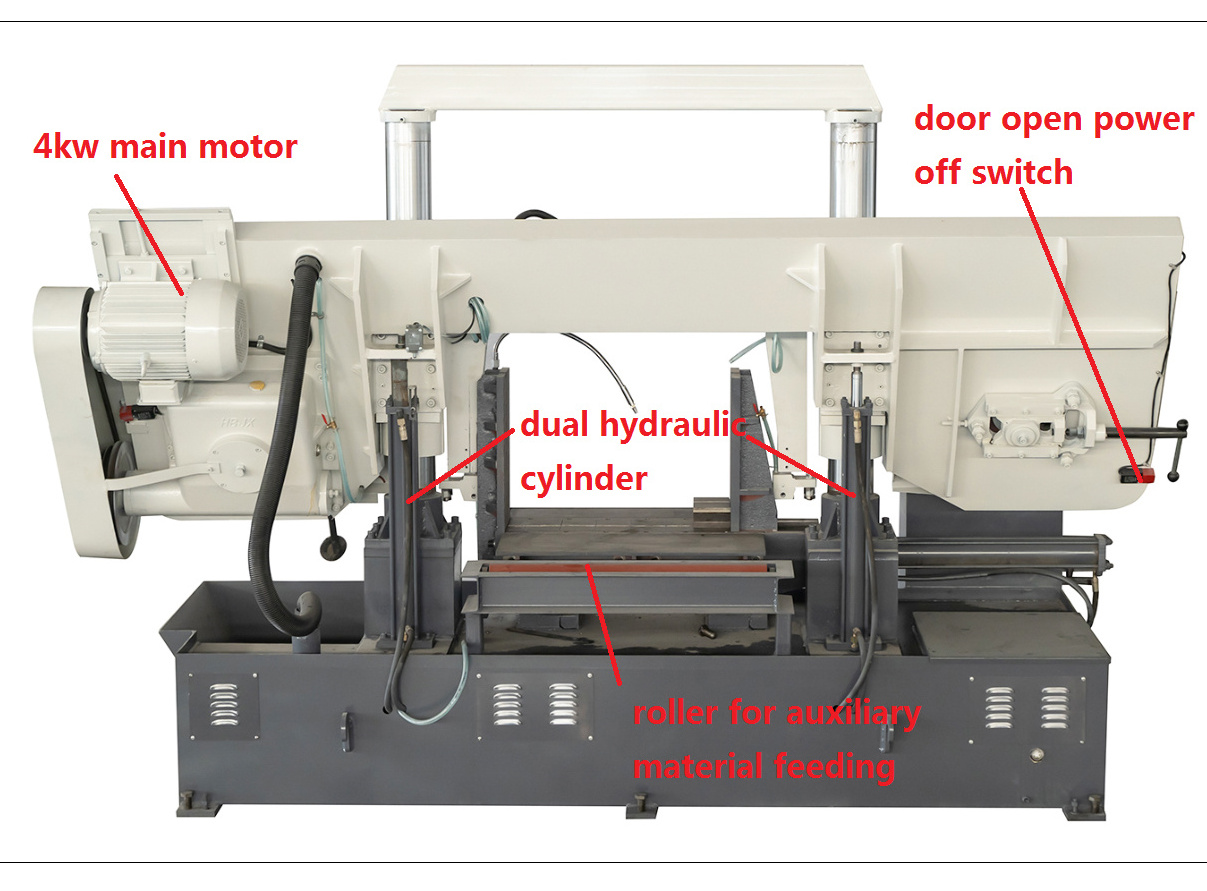

METAL BAND SAW MACHINING

Metal band saw machines are mainly used for low alloy steel, high alloy steel, special alloy steel and stainless steel. According to the structure, it is divided into horizontal metal band sawing machine and vertical metal band sawing machine. The horizontal type is divided into scissor type, double column and single column type band sawing machine; according to the usage, it is divided into manual type (economical manual feeding and manual cutting of materials), Automatic type; According to the automation program using the controller, it can be divided into manual type (semi-automatic manual feeding) and fully automatic type (automatic feeding and automatic cutting); according to the cutting angle requirements, it can be divided into angle sawing machine (can cut angles of 90 degrees and 45 degrees) without angle That is a 90 degree vertical cut.

FEATURES

1. Double column structure ensures the stability and accuracy of cutting.

2. Hydraulic and manual clamping, the cut work piece is firmly fixed, to avoid the breakage of band saw.

3. Hydraulic step less feeding speed, and saw blade speed controlled by cone pulley.

4. Specially designed for mass cutting, adopting 27 widths, band saw blade with high cutting accuracy and fast speed.

5. Angle rotation is regulated by manual, and angle read by scale.

6. The main drive adopts worm gear reducer, which has strong power and reliable performance. After precise balance correction, the operation is stable and reliable.

7. Narrow saw mouth, material saving and energy saving.

8. The reasonable saw band guide device can effectively prolong the service life of the saw band, and the movable saw blade guide device has stable structure and flexible movement. The transmission parts are accurately balanced and corrected to reduce vibration and the falling speed is stable. This precision system can prevent abnormal damage of the saw blade and achieve the ideal sawing effect.

9. The high-efficiency and energy-saving circuit with simple design and excellent space of the electrical box not only ensure the low failure rate of the machine, but also facilitate maintenance and save time;

10. Working light for working area

11. Steel wire brush for cleaning and removing the cut chips of blade to prolong the blade’s service life.

PRODUCT CONFIGURATION

Button interfance

Sample operation.

High efficiency.

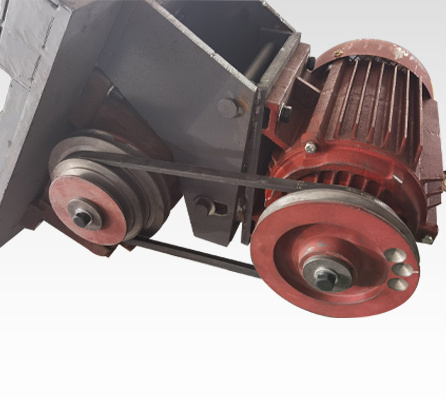

Motor

1.Using copper core motors.Increase turbine reducer.

2.Ensure long-term and efficient work

Supporter

Standard pallet support which can support the pieces.

Saw wheel

Reducing torque and prolonging theservice life of saw blade

Saw blade

Band saw blades have high hardness and good wear resistance. It can cut stainless steel, mold steel, titanium steel, copper, aluminum and ordinary steel, etc.

Electrical cabinet

Standard with Famous Electrical.Schneider $ DELIXI available.

Parameters

|

Model

|

G-280(Pivot miter)

|

|

G-330(Pivot miter)

|

G-350(Pivot miter)

|

|||

|

Maximum cutting capacity (mm)

|

0 °

|

P280mm 350mm( W) x 280mm( H)

|

D330mm 450mm( W)x 305mm( H)

|

D350mm 480mm( W) x 350mm( H)

|

|||

|

|

士45°

|

Pmm 280mm(W)x 280mm( H)

|

P300mm 305mm (W)x 305mm(H)

|

P320mm 320mm (W)x 320mm( H)

|

|||

|

|

-60°

|

P200mm 200mm (W)x 200mm(H)

|

P200mm 220mm(W)x 305mm(H)

|

P220mm 220mm (W)x 300mm(H)

|

|||

|

Sawing angle

|

士45°~-60°

|

|

|

|

|||

|

Main motor power

|

2.2KW

|

2.2KW

|

2.2KW

|

2.2KW

|

|||

|

Oil pump power

|

0.42KW

|

|

0.42KW

|

0.42KW

|

|||

|

Water pump power

|

0.04KW

|

|

0.04KW

|

0.04KW

|

|||

|

Saw blade speed (m/min )

|

40/60/80 regulating by cone pulley

|

|

|

|

|||

|

Saw blade size (mm)

|

4115x27x0.9mm

|

|

|

34x1.1mm

|

|||

|

Work piece clamping

|

Manual and Hydraulic

|

|

|

Manual and Hydraulic

|

|||

|

Saw blade tension

|

Manual

|

|

|

Manual

|

|||

|

Main drive

|

Worm gear

|

|

|

Worm gear

|

|||

|

Material feeding type

|

Roller auxiliary feeding

|

|

|

Roller auxiliary feeding

|

|||

|

Work table height (mm)

|

750mm

|

|

|

750mm

|

|||

|

Over size(LxWxH)

|

1800x900x1450mm

|

|

1900x900x1450mm

|

2100x900x1450mm

|

|||

|

Net weight(kg) (approximate)

|

800

|

850

|

850

|

900

|

|||

Samples

Machine working show

Recommend Products

Hot Searches