- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Ho Chi Minh City, Vietnam

-

Brand Name:

-

Viet Mechanical

-

Model Number:

-

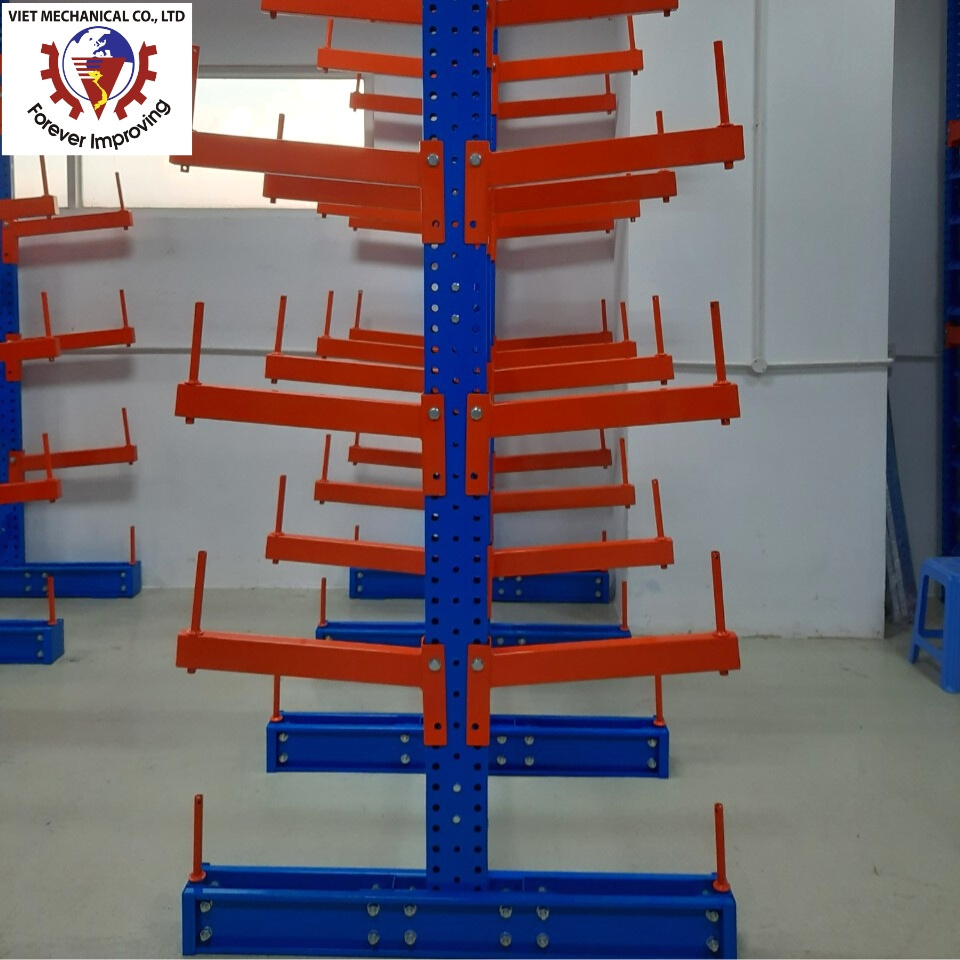

Heavy Duty Roll-Formed Cantilever Rack

-

Depth:

-

3.0-4.5mm or customized

-

Weight Capacity:

-

1500Kg/Arm Max

-

Width:

-

Customized

-

Height:

-

Customize

-

Finish:

-

Hot Dip Gavanized; Powder Coating

-

Package:

-

Standard Exported Package

-

Payment Terms:

-

50% Deposit 50% Balanced

-

Warranty:

-

24 Months

-

Color:

-

Customized Color

-

Delivery time:

-

30 days or more depending on quantity

-

Service:

-

Customer Designs

-

Certification:

-

CE

Quick Details

-

Type:

-

Multi-Level

-

Material:

-

G450, G550, SS400, SS490 High Class Carbon Steel

-

Feature:

-

Corrosion Protection

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Ho Chi Minh City, Vietnam

-

Brand Name:

-

Viet Mechanical

-

Model Number:

-

Heavy Duty Roll-Formed Cantilever Rack

-

Depth:

-

3.0-4.5mm or customized

-

Weight Capacity:

-

1500Kg/Arm Max

-

Width:

-

Customized

-

Height:

-

Customize

-

Finish:

-

Hot Dip Gavanized; Powder Coating

-

Package:

-

Standard Exported Package

-

Payment Terms:

-

50% Deposit 50% Balanced

-

Warranty:

-

24 Months

-

Color:

-

Customized Color

-

Delivery time:

-

30 days or more depending on quantity

-

Service:

-

Customer Designs

-

Certification:

-

CE

Specification

|

Item

|

Value

|

|

Product Name

|

Cantilever Racking

|

|

Model Number

|

Heavy Duty Roll-Formed Cantilever Rack

|

|

Material

|

G450, G550, SS400, SS490 High Class Carbon Steel

|

|

Use

|

Warehouse Rack

|

|

Weight Capacity

|

1500Kg/Arm Max

|

|

Height

|

Customized

|

|

Color

|

Customized Color

|

|

MOQ

|

1 Set

|

|

Delivery time

|

15-30days depending on quantity

|

|

Brand Name

|

Viet Mechanical

|

|

Feature

|

Corrosion Protection

|

|

Warranty

|

24 Months

|

|

Usage

|

Warehouse Storage System

|

|

Packing

|

Standard Exported Package

|

|

Service

|

Customer Designs

|

|

Finish

|

Hot Dip Gavanized; Powder Coating

|

|

Certification

|

CE

|

Product Description

Advantages of using Cantilever Racking

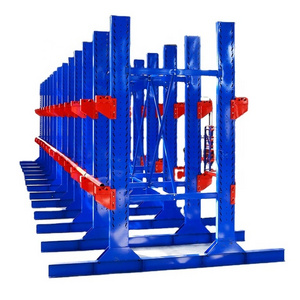

Space saving:

Compared to leaving goods scattered on the warehouse floor, which takes up a lot of space and is difficult to load and unload, using a Cantilever racking will help your goods be neatly stored in a scientific way, saving many space for your warehouse.

Flexibility in installation:

With the ability to easily disassemble, the installation can flexibly adjust the number of support arms, the height distance to fit different types of goods.

Satisfy your storage needs:

Storing goods on cantilever rack will increase the density of goods, neatly arranged goods help to choose the correct type of goods to be imported and exported, help operate more efficiently and quickly.

Outstanding load:

Exceptional storage capacity with loads up to 5000kg - 6000kg/floor. This type of rack is produced depending on the needs of the customer and the type of goods to be stored.

High Quality storage racking:

With high-quality steel material, Cantilever rack has outstanding quality and has the strength to withstand deformations due to impact. With flexible adaptability to all types of warehouses and stored goods. Cantilever racking is always a safety measure for both stored goods and operators.

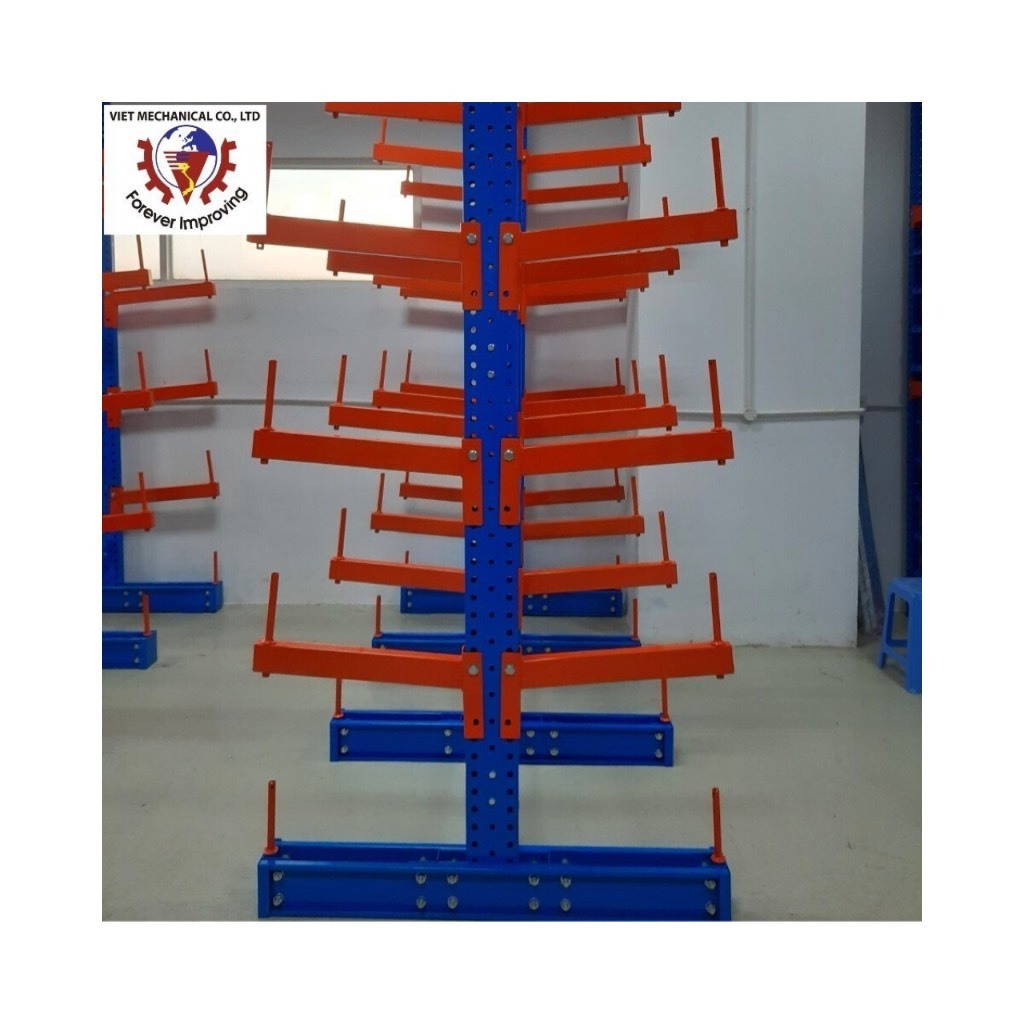

Cantilever racks installed in viet mechanical’s customer which carried long products

Technical components of the Cantilever racking system

Basically, the Cantilever racking has two main parts: Uprights and support arms. And other components such as: base plate, arm stop, cross bracing, bracing set, base pat, foot pads, switch mill...

Uprights:

Uprights are made of profiled steel with modern machines, the thickness of the column depends on the desired load of the customer. Uprights can be made from one to two columns to match the load capacity of the goods.

There are holes on each uprights for mounting brackets with hooks or bolts for height adjustment. The distance between the pillars is 2 to 7.5m or other sizes based on customer's requirements.

Support arms:

As one of the main parts of the racking system, it is manufactured from profiled steel with different sizes. The supporting arms are attached to uprights using a pat or bolt.

The Support arms are designed depending on the type of cargo, cargo load, loading and unloading method and the unique needs of the customer.

The support arms are placed at a certain inclination and the top of the support arm is equipped with a latch to prevent the goods from falling during storage. On the support arm can be marked for easy management by the operator.

Annotation of the main components in the cantilever racking system

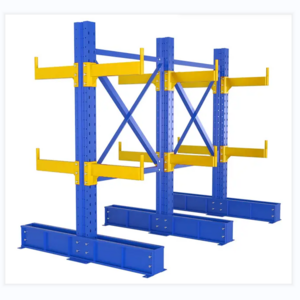

Other ingredients:

-

Base plate

: This is the part that is in direct connect with the floor of the warehouse and the base is fixed by foot pads, helping the system to be firm and fixed.

-

Bracing set

: The part that connects all the uprights together, forming a solid and stable block for the racking system.

-

Signage

: This is a sign to list the technical characteristics of the racking system. They are placed in visible areas.

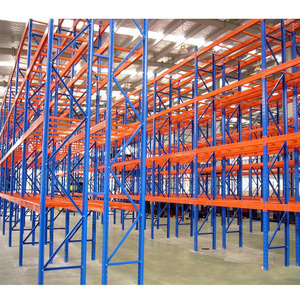

Building the racking house:

This is a form of installation based on the original ideas to make the most of the surface area and height, used as a shelf to store specialized support. The construction will need to calculate the building load, external impacts such as environment, weather,... and the load of stored goods. However, this has the advantage of being easier to install, flexible and specialized.

Cantilever racking house system

Hot Searches