- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Accord to the country

-

Power:

-

Accord to the country

-

Dimension(L*W*H):

-

Accord to the product

-

Application:

-

Industries

-

Heating method:

-

Electricity

-

Usage:

-

Powder Coating Workpieces

-

Technology:

-

Automatic

-

Coating color:

-

Multi Color

-

Coating Technology:

-

Low Temperature Deposition

-

Install location:

-

Spraying Room

-

Item:

-

Powder Coating Pump

-

Product name:

-

Powder Coating System

-

Keywords:

-

Painting Production Line

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Viet Nam, Mexico

-

Weight:

-

Accord to the product

-

Certification:

-

ISO 9001

Quick Details

-

Machine Type:

-

Coating

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Guanjie

-

Voltage:

-

Accord to the country

-

Power:

-

Accord to the country

-

Dimension(L*W*H):

-

Accord to the product

-

Application:

-

Industries

-

Heating method:

-

Electricity

-

Usage:

-

Powder Coating Workpieces

-

Technology:

-

Automatic

-

Coating color:

-

Multi Color

-

Coating Technology:

-

Low Temperature Deposition

-

Install location:

-

Spraying Room

-

Item:

-

Powder Coating Pump

-

Product name:

-

Powder Coating System

-

Keywords:

-

Painting Production Line

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Viet Nam, Mexico

-

Weight:

-

Accord to the product

-

Certification:

-

ISO 9001

Product Application

Welcome to Guanjie, and we are the factory to produce the Liquid Painting Line, Powder Coating Line and Logistics Transport Line. All equipment is customized for your product requirement.

|

SPECIFICATIONS FOR POWDER COATING LINE

|

|

|

|

|||

|

Process parameters

|

Substrate

|

Metal, steel, aluminum

|

|

|||

|

|

Workpiece

|

Home, bath & kitchen schools and office furniture metal parts

|

|

|||

|

|

Coating type

|

Low temperature coating

|

|

|||

|

Main performance parameters

|

Conveyor chain speed

|

m/min

|

0.8

|

|||

|

|

Adjustable speed

|

m/min

|

0.4-2

|

|||

|

|

Theoretical maximum capacity

|

m

2

/h

|

2000pcs/8h

|

|||

Technical Process

Part preparation processes and equipment

can be done by a variety of chemical and mechanical methods. The selection of the method depends on the size and the material of the part to be powder coated, the type of impurities to be removed and the performance requirement of the finished product.

Main Features

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint.

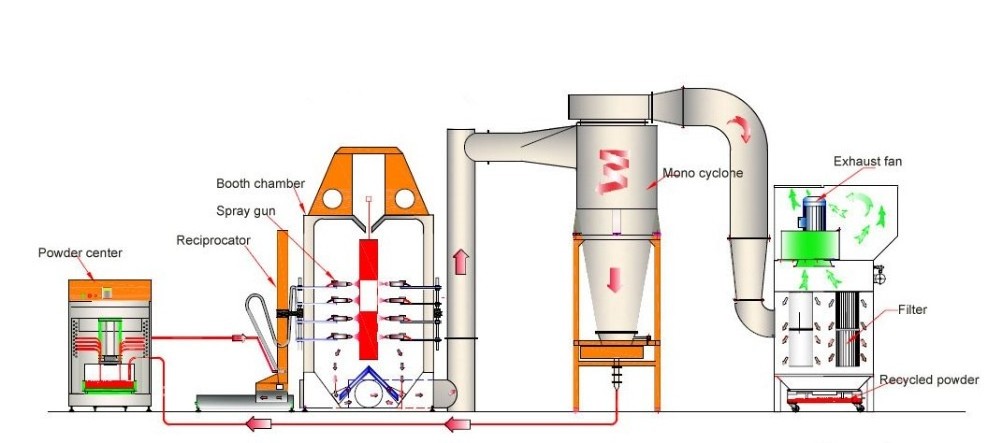

Powder Recycle Flow

2. Quick color change (10-15 minutes automatic color change)

3. Powder recovery rate as high as 99.2%

4. Fifth generation of intelligent spray gun, the workpiece groove has no bottoming phenomenon

5. Full consider the need for color change, easy to clean

6. Key mechanical parts and electrical components of the equipment adopt the world’s top brand products to ensure reliable operation and durability

7. Beautiful appearance, fine workmanship

Advantages over other coating processes

2. Powder coatings can produce much thicker coatings than conventional liquid coatings without running or sagging.

5. Curing time is significantly faster with powder coating than with liquid coating.

Powder supply center

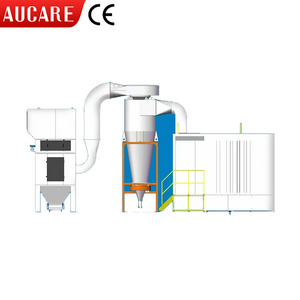

Powder spraying booth

Automatic transmission chain

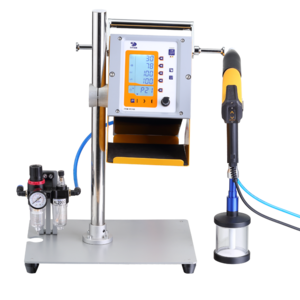

Powder spray gun

Powder coating

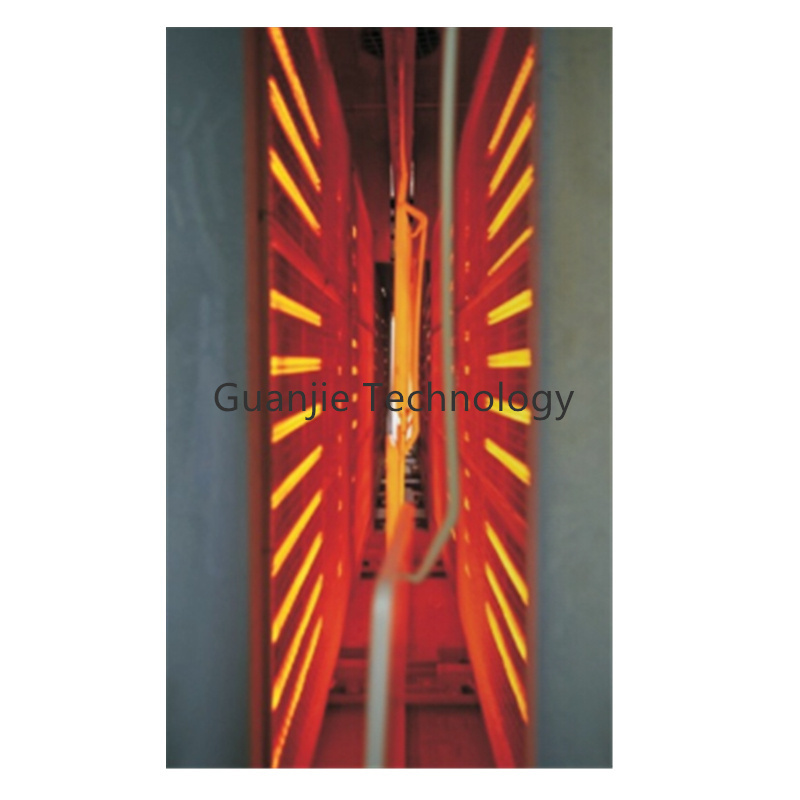

Baking oven

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

More about us

Q: What does your company do?

A: Our company produce different kinds of solid and durable coating equipment. We provide automatic coating system and conveyor system to the customers who need to establish or improve their coating factory.

Q: Is your company a factory or a trade company?

A: We are a factory that is located in Daya Bay, Huizhou, Guangdong. We rely on the advantages of our factory to give you the best offer at the best quality, and we are always welcoming your visit.

Q: Quality service?

A: After receive your inquiry, our engineers will respond to you within 2 hours. No matter pre-sale or after-sale, we are always focusing on the questions from customers .