- Product Details

- {{item.text}}

Quick Details

-

Power:

-

380-440v

-

Dimension(L*W*H):

-

Great Variety

-

Warranty:

-

1 Year, One Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Colour:

-

It depends

-

Raw material:

-

Scrap & billet

-

Finished product:

-

Rebar, steel angle, flat bar, wire rod, etc.

-

Production capacity:

-

10000T-5000000T per year

-

Certification:

-

ISO9001,BV,AAA, ISO9001,BV,AAA

-

Packaging:

-

Wooden box & Nude

-

Delivery details:

-

3 months

-

Weight:

-

Uncertain

Quick Details

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

HANI

-

Voltage:

-

380V

-

Power:

-

380-440v

-

Dimension(L*W*H):

-

Great Variety

-

Warranty:

-

1 Year, One Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Colour:

-

It depends

-

Raw material:

-

Scrap & billet

-

Finished product:

-

Rebar, steel angle, flat bar, wire rod, etc.

-

Production capacity:

-

10000T-5000000T per year

-

Certification:

-

ISO9001,BV,AAA, ISO9001,BV,AAA

-

Packaging:

-

Wooden box & Nude

-

Delivery details:

-

3 months

-

Weight:

-

Uncertain

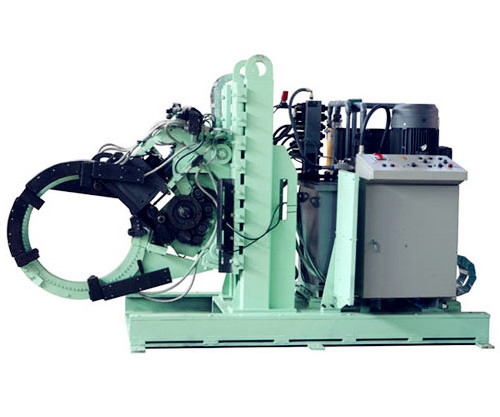

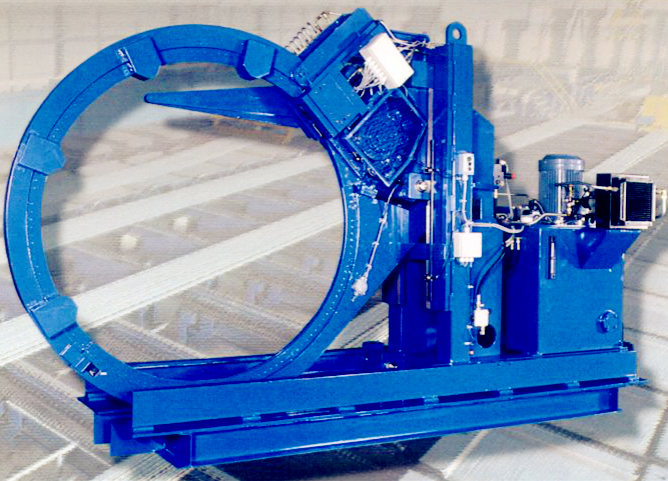

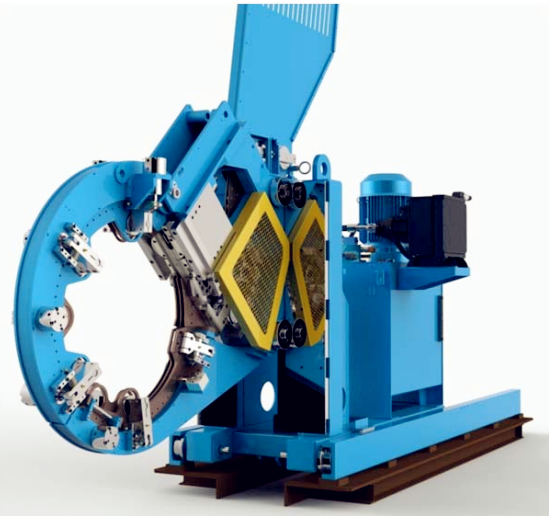

Product Instruction

Wire rod block mill is composed of top crossed 45°high-speed wire-rod mills / finishing mills. The finishing mill group/wire rod mill is located in high-speed wire-rod workshop. Through several unit rack the continuous micro-tension rolling mill will be transported upstream Ø17 ~Ø21mm of rolling, rolling become Ø5.5 ~ Ø16mm finished wire. The working speed of 90m/s, 135m/s etc.

Main Features

1) Mill stand use top crossed 45℃ composition form to achieve no twisting, no contact axis, little axis and shock for equipment, besides, it decrease the center of gravity height, the stability increased as well, while, the total weight has decreased and it is very easy to maintain. Ten stands are concentrated transmission.

2) Roll frame is composed of roller box, bevel gearbox and spare parts of bevel gearbox.

3) Roller box and bevel gearbox adopt outside combinational instruction.

4) Roller loop is tungsten carbide, it is connected on the cantilever roll shaft, we use the specific hydraulic changing roll equipment to replace roll loop, it is convenient and easy.