- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HWASEN

-

Voltage:

-

220V/380V,3phase

-

Dimension(L*W*H):

-

8.4X6X3.5M

-

Power (kW):

-

200

-

Weight:

-

7000 KG

-

bubble layer:

-

1layer

-

film width:

-

1500mm/500mmx3

-

cooling way:

-

water cooling

-

feeding granule:

-

auto feeder

-

gear box:

-

FUHE, CHANGZHOU

-

inverter:

-

DELTA

-

roll change:

-

automatic

-

paper core change:

-

automatic

-

film thickness:

-

0.008-0.05mm

-

film layer:

-

3layers

Quick Details

-

Screw Design:

-

Triple Screw

-

Screw L/D Ratio:

-

30:1

-

Screw diameter (mm):

-

60/70/90

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HWASEN

-

Voltage:

-

220V/380V,3phase

-

Dimension(L*W*H):

-

8.4X6X3.5M

-

Power (kW):

-

200

-

Weight:

-

7000 KG

-

bubble layer:

-

1layer

-

film width:

-

1500mm/500mmx3

-

cooling way:

-

water cooling

-

feeding granule:

-

auto feeder

-

gear box:

-

FUHE, CHANGZHOU

-

inverter:

-

DELTA

-

roll change:

-

automatic

-

paper core change:

-

automatic

-

film thickness:

-

0.008-0.05mm

-

film layer:

-

3layers

LYM-1500x3C High Speed 3 Layers Cast Stretch Airport Luggage Wrapping Film Making Machine

1.APPLICATION:

1)this machine adopt LLDPE as the basic mateiral, adopt different type of resin, extrusion the single side sticky or double side sticky stretch/cling film;

2)This film with strong tension, it both with good retraction memory and self-sticky, can let the goods package well, then can avoid the goods collapse or dirty pollution on the transport way.

3)The film with good transparency and extensibility,this stretch film widely used for big goods Unitized pallet packag e, it is the great replacement product for the hot shrink film.

2.MAIN TECHNICAL SPECIFICATION

|

Model |

LYM-1 5 00× 3C |

|

Suitable material |

LLDPE/LDPE /CPE |

|

Screw diameter |

60mm/90mm/70mm |

|

Screw L/D ratio |

3 2 :1 |

|

Die head width |

190 0mm |

|

Finished product width |

1 5 00 mm/ 5 00 mm× 3roll |

|

Film thickness |

0.0 09 -0.05mm |

|

Film structure |

A/B /C co-extrude |

|

Max. Output capacity |

200-250KG/H |

|

Machine liner speed |

50-100m/min |

|

rewinding speed |

50-80m/min |

|

Total power |

200 kw |

|

Dimension |

8.4 × 6 × 3 .5 m |

|

Total weight |

70 00kg |

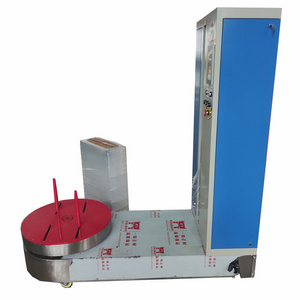

3.Mchine picture show

1) three screw co-extruder

3) die head

3)automatic roll change

4)stretch film quality show

5)automatic paper core change system

6) water cooling chiller