- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/450V

-

Dimension(L*W*H):

-

According to different model

-

Weight:

-

According different model to

-

Warranty:

-

12 Months

-

Local Service Location:

-

None

-

Product name:

-

Linear Vibrating Screen

-

Keyword:

-

Vibrating screen

-

Material:

-

Stainless Steel/Carbon Steel

-

Function:

-

Screening\separation\sorting\sieving

-

Layer:

-

1-5 Layers

-

Capacity:

-

10Kg-10Tons/hour

-

Frequency:

-

50HZ/60Hz/Optional

-

Diameter:

-

400-2000mm

-

Color:

-

Customer's request

-

Name:

-

China grain separator machine linear vibrating screen

-

Certification:

-

ISO9001:2008

Quick Details

-

Type:

-

LINEAR

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SANYUANTANG

-

Voltage:

-

220V/380V/415V/450V

-

Dimension(L*W*H):

-

According to different model

-

Weight:

-

According different model to

-

Warranty:

-

12 Months

-

Local Service Location:

-

None

-

Product name:

-

Linear Vibrating Screen

-

Keyword:

-

Vibrating screen

-

Material:

-

Stainless Steel/Carbon Steel

-

Function:

-

Screening\separation\sorting\sieving

-

Layer:

-

1-5 Layers

-

Capacity:

-

10Kg-10Tons/hour

-

Frequency:

-

50HZ/60Hz/Optional

-

Diameter:

-

400-2000mm

-

Color:

-

Customer's request

-

Name:

-

China grain separator machine linear vibrating screen

-

Certification:

-

ISO9001:2008

China grain separator machine linear vibrating screen for sieving various grains

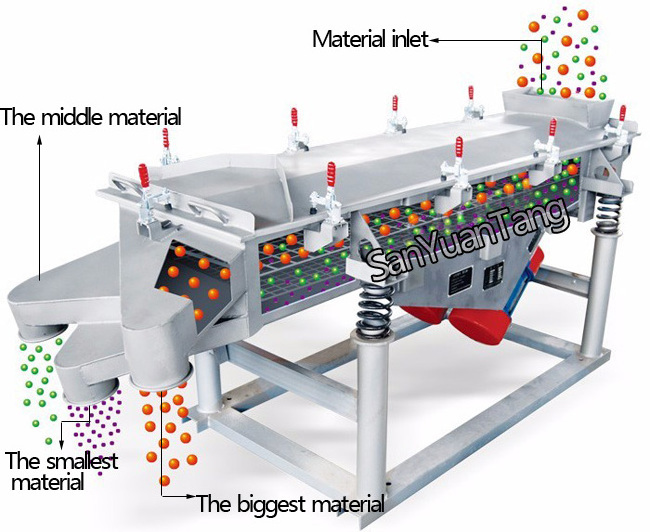

Describe——Linear Vibrating Screen

SYZ linear vibrating screen use excellent vibrating motor as power source,that the materials can be thrown up on the sieve and forward to make a straight movement. It can be equipped with single or multi-screen to achieve the grading, removing impurity, removing dust, testing, washing selecting, dehydration,cleaning raw material,separation of iron from the material,etc.

Technical Parameter——Linear Vibrating Screen

|

Model |

SYZ-520 |

SYZ-840 |

SYZ-1030 |

SYZ-1255 |

SYZ-1650 |

|

Dimension(mm) |

500*2000 |

800*4000 |

1000*3000 |

1200*5500 |

1600*5000 |

|

Granularity(mm) |

0.074-60 |

0.074-60 |

0.074-60 |

0.074-60 |

0.074-60 |

|

Speed(r/min) |

960 |

960 |

960 |

960 |

960 |

|

Amplitude |

4-8 |

4-8 |

4-8 |

4-8 |

4-8 |

|

Deck |

1-4 |

1-4 |

1-4 |

1-4 |

1-4 |

|

Power(kw) |

2×0.75 |

2×1.5 |

2×1.9 |

2×2.2 |

2×3.0 |

Features——Linear Vibrating Screen

1.Easy to operate and maintain.

2.Low consumption with high yield and low cost.

3.Fully enclosed structure, automatic layout, more suitable for pipeline operations.

4.Good sealing without dust flying.

5.Can be used for single or multi layer.

6.Material auto discharge, be able to continuous operation.

7.Every part of the screen box used copper plate and section welded together.

Working Principle——Linear Vibrating Screen

SYZ Linear vibrating screen uses double vibrating motors to drive,when two motors rotate synchronously and reversely, exciting forces generated by eccentric block are resolved in parallel to the direction of motor axis and then united as one across the motor axis direction,so its movement track is linear.There is an angle of inclination between the two motor axises relative to the screen deck. Under the influence of the resultant force of exciting force and materiels itself weight,materiels are thrown up to make leapfrog and linear movement forward on the screen deck in order to screen and grade the materiel .Applied in flowing line to achieve automatical operation.

Application in details——Linear Vibrating Screen

1.Chemical industry: resin pigment, medicine, grease, paint, palette, etc.

2.Organic fertilizer industry.

3.Plastics industry.

4.Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

5.Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc.

6).Paper-making industry: coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

7.Metallurgy and mining industry: quartz sand, ore, titanium oxide, zinc oxide, etc.

8.Mechanical industry: casting sand, powder metallurgy, electromagnetic material and metal powder, etc

Actual photos:

Specially designed according to customer's requirements

1.Linear vibrating screen with magnet , in the screening of raw materials at the same time,it can remove the iron in the raw material.

2.Linear vibrating screen with water spray device,in the screening of raw materials at the same time,it can cleaning the raw material.

1.Machine Packing:

Our machine uses export standard wooden packing for our customers.

2. Machine Shipping:

We usually ship machines for our customers with the following modes:

1). by sea 2). by air 3). by express 4). by train

3. Delivery time:

We will delivery your machines in 5-10days after received 100% of the whole payment.