- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yuanda Boiler

-

Dimension(L*W*H):

-

7x2.5x3.5m

-

Weight:

-

18t-40t

-

Product name:

-

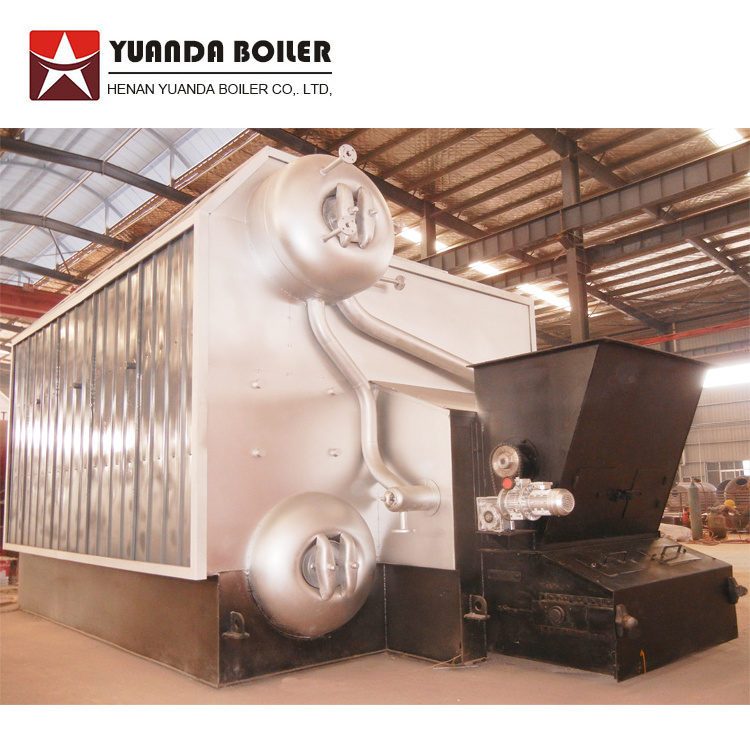

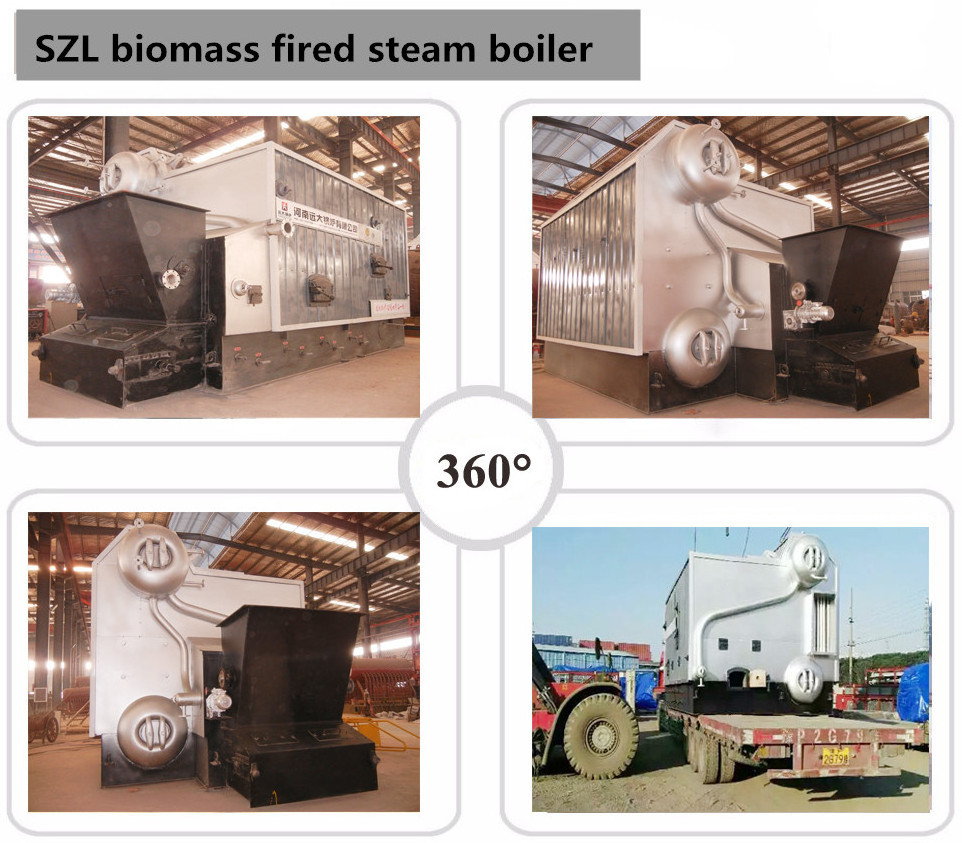

SZL6-1.25-AII 6 ton biomass pellet coal wood chips husk steam boiler

-

operation style:

-

automatic chain grate stoker biomass boiler

-

structure:

-

big furnace two drum water tube

-

capacity:

-

2ton-20ton per hour

-

Design pressure:

-

0.4-2.5Mpa

-

Steam temperature:

-

184/194/205/225

-

Thermal efficiency:

-

>83%

-

Material:

-

Q345R Steel Plate

-

Certification:

-

ISO CE SGS

Quick Details

-

Core Components:

-

boiler body

-

Steam Production:

-

6 ton

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuanda Boiler

-

Dimension(L*W*H):

-

7x2.5x3.5m

-

Weight:

-

18t-40t

-

Product name:

-

SZL6-1.25-AII 6 ton biomass pellet coal wood chips husk steam boiler

-

operation style:

-

automatic chain grate stoker biomass boiler

-

structure:

-

big furnace two drum water tube

-

capacity:

-

2ton-20ton per hour

-

Design pressure:

-

0.4-2.5Mpa

-

Steam temperature:

-

184/194/205/225

-

Thermal efficiency:

-

>83%

-

Material:

-

Q345R Steel Plate

-

Certification:

-

ISO CE SGS

SZL6-1.25-AII 6 ton biomass pellet coal wood chips rice husk fired steam boiler

1. Boiler capacity:1-20ton/h

2.Stem pressure:1.0Mpa(10bar),1.25Mpa(13bar), 1.6Mpa(16bar), 2.5Mpa(25bar)

3.Steam temperature output:184C,194C,204C,225C.

4.Suitale fuel: biomass, wood pellet,peanut, paddy, rice husk, solid fuel,etc

5.Structure: water tube, big cyclone room

6. Application:industrial production and processing.

II.Suitable fuels

Biomass, wood pellet,wood chips, peanut, paddy, rice husk,palm oil shell,solid fuel,etc

| Boiler model | Rated capacity |

Rated pressure

|

Rated steam tempe rature

|

Active great area |

Boiler heating area |

Fuel consu mption |

Thermal effiency | Weight |

Diem ension |

| ton/h | Mpa | ℃ | m2 | m2 | KG/h | % | ton | mm | |

| SZL2-1.25/1.6/2.5-T | 2 | 1.25/1.6/2.5 | 194/204/226 | 3.1 | 64.6 | 350 | 82 | 20/23/25 | 5960*2960*3468 |

| SZL4-1.25/1.6/2.5-T | 4 | 1.25/1.6/2.5 | 194/204/226 | 4.6 | 115.4 | 705 | 82 | 28/28.5/29 | 6510*3130*3468 |

| SZL6-1.25/1.6/2.5-T | 6 | 1.25/1.6/2.5 | 194/204/226 | 7.3 | 136.3 | 1058 | 82.6 | 38/40/42 | 7830*3346*3468 |

| SZL8-1.25/1.6/2.5-T | 8 | 1.25/1.6/2.5 | 194/204/226 | 10.4 | 173 | 1411 | 82.6 | 52 | 8200*3346*3468 |

| SZL10-1.25/1.6/2.5-T | 10 | 1.25/1.6/2.5 | 194/204/226 | 11.8 | 233 | 1764 | 82.6 | 68 | 8500*3346*3482 |

| SZL12 -1.25/1.6/2.5-T | 12 | 1.25/1.6/2.5 | 194/204/226 | 15.4 | 307.3 | 2117 | 83 | 30 | 9000*3400*3550 |

| SZL15-1.25/1.6/2.5-T | 15 | 1.25/1.6/2.5 | 194/204/226 | 17.7 | 280.5 | 2647 | 83 | 35 | 9583*3400*3550 |

| SZL20 -1.25/1.6/2.5-T | 20 | 1.25/1.6/2.5 | 194/204/226 | 20.9 | 725.2 | 3520 | 83 | 40 | 11600*3460*3520 |

|

Notice:

1. "T" represents all kinds of biomass.

2.The parameters are for refeence, if the technology is improved,please refer to the data showed on drawing. |

|||||||||

1. National Scientific and Technological Progress Second Prize.

2. Singapore New Product Expo Golden Lion Award

3. With special fuel hopper and fuel discharge device.

4.Three pass boiler. The smoke go through three phase, making the boiler have higher heat transfer efficiency and lower smoke temperature emissed.

5.The hearth is designed with a cyclone reburning chamber, which makes the boiler energy saving, high combustion efficiency and environmental friendly.

6.Special air distribution design.

7.The hearth has large volume and strong fuel adaptability, it can use various biomasses as the fuel.The big size furnace can be well adapted to biomass's feature of high flame.

The size of some most common biomass fuel:

(1).Biomass/wood pellets:≤Φ10×30 mm

(2).Wood chips:≤100×50×50 mm

(3).Sawdust:≤20×20×10 mm

8.The arch is specially designed accordign to the fuel.

9.Design of preventing fouling, slagging and corrosion of heating area.

10. It has a double-drum offset hearth (D-type layout) with furnace in the right side of the boiler and two drums in the left side of the boiler, the structure is very compact.

1. Nude packaging for boiler mian part and wood box packaging for boiler accessories.

2.Normally we use 20 container, 40container or 20 flat rack container and 40 flat rack container to load it.

3.All goods will be reforced after packing into containers.

4. We have stable shipping company to cooperate. They will confirm the safty of the goods.

5. Shipping way is different according to customer's country. Mostly by sea. Some country by train.

Pre-sale service:

We help customer choose the best boiler model according to different requirements of various industry. Before delivery we will provide foundation drawing, layout drawing, boiler room layout, etc.

In-sale service:

We keep 24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product.

After-sale service:

1.provide full range of original spare parts.

2.Engineers abroad installation and commissioning service is available.

3.Our engineers will held a training for boiler workers to ensure the safe operation.

4.Free maintenance and repair for one year and lifelong service.