PE pipe inner wall is smooth with features of low friction resistance and energy saving and does not change with the use of

time.Its pressure loss is about 30% smaller than steel pipe, therefore,smaller pe pipe is a better way than steel pipe.PE pipe has

good hygienic performance with no additives, so it is impossible to pollute the drinking water.Polyethylene material level is 0

(the lowest level) in ISO standard and it is moldy material. Compared with other commonly used plastic materials,mildew resistance

of polyethylene is much higher resulting a long term use without scaling.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

ZS-PE-07

-

Specification:

-

dn16mm to dn1600mm

-

Length:

-

5.8 or 11.8m per piece, 5.8m/pc or 11.8m/pc

-

Thickness:

-

2mm to 118mm

-

Standard:

-

ISO4427, ASTMF714

-

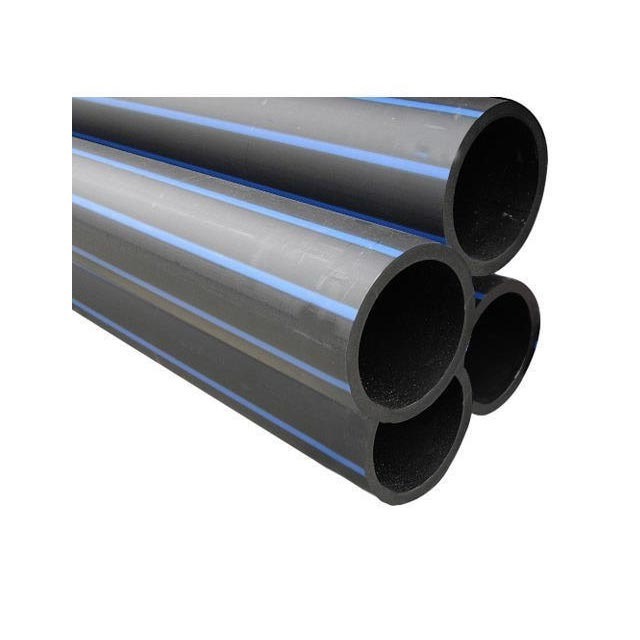

Color:

-

Black with blue strip, Blue or as requirement

-

Connection:

-

butt fusion,fabricated,flange

-

Pressure:

-

PN4,PN6,PN8,PN10,PN12.5,PN16,PN20,PN25

-

Working Temp:

-

- 40℃ to 40℃

-

Usage:

-

drinking water supply

-

Certification:

-

ISO9001 14001

-

Raw material:

-

High Density Polyethylene

-

Delivery Time:

-

7 days

-

Production capacity:

-

20000 Meters/Day

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHUOSHI

-

Model Number:

-

ZS-PE-07

-

Specification:

-

dn16mm to dn1600mm

-

Length:

-

5.8 or 11.8m per piece, 5.8m/pc or 11.8m/pc

-

Thickness:

-

2mm to 118mm

-

Standard:

-

ISO4427, ASTMF714

-

Color:

-

Black with blue strip, Blue or as requirement

-

Connection:

-

butt fusion,fabricated,flange

-

Pressure:

-

PN4,PN6,PN8,PN10,PN12.5,PN16,PN20,PN25

-

Working Temp:

-

- 40℃ to 40℃

-

Usage:

-

drinking water supply

-

Certification:

-

ISO9001 14001

-

Raw material:

-

High Density Polyethylene

-

Delivery Time:

-

7 days

-

Production capacity:

-

20000 Meters/Day

Products Description

HDPE Pipe

Specification:

Unit:mm

|

PE100

|

0.4MPa

|

0.5MPa

|

0.6MPa

|

0.8MPa

|

1.0MPa

|

1.25MPa

|

1.6MPa

|

2.0MPa

|

2.5MPa

|

||||||||

|

Outside Diameter

|

PN4

|

PN5

|

PN6

|

PN8

|

PN10

|

PN12.5

|

PN16

|

PN20

|

PN25

|

||||||||

|

|

SDR41

|

SDR33

|

SDR26

|

SDR21

|

SDR17

|

SDR13.6

|

SDR11

|

SDR9

|

SDR7.4

|

||||||||

|

|

Wall Thickness (en)

|

|

|

|

|

|

|

|

|

||||||||

|

20

|

-

|

-

|

-

|

-

|

-

|

-

|

2.0

|

2.3

|

3.0

|

||||||||

|

25

|

-

|

-

|

-

|

-

|

-

|

2.0

|

2.3

|

3.0

|

3.5

|

||||||||

|

32

|

-

|

-

|

-

|

-

|

2.0

|

2.4

|

3.0

|

3.6

|

4.4

|

||||||||

|

40

|

-

|

-

|

-

|

2.0

|

2.4

|

3.0

|

3.7

|

4.5

|

5.5

|

||||||||

|

50

|

-

|

-

|

2.0

|

2.4

|

3.0

|

3.7

|

4.6

|

5.6

|

6.9

|

||||||||

|

63

|

-

|

-

|

2.5

|

3.0

|

3.8

|

4.7

|

5.8

|

7.1

|

8.6

|

||||||||

|

75

|

-

|

-

|

2.9

|

3.6

|

4.5

|

5.6

|

6.8

|

8.4

|

10.3

|

||||||||

|

90

|

-

|

-

|

3.5

|

4.3

|

5.4

|

6.7

|

8.2

|

10.1

|

12.3

|

||||||||

|

110

|

-

|

-

|

4.2

|

5.3

|

6.6

|

8.1

|

10.0

|

12.3

|

15.1

|

||||||||

|

125

|

-

|

-

|

4.8

|

6.0

|

7.4

|

9.2

|

11.4

|

14.0

|

17.1

|

||||||||

|

140

|

-

|

-

|

5.4

|

6.7

|

8.3

|

10.3

|

12.7

|

15.7

|

19.2

|

||||||||

|

160

|

-

|

-

|

6.2

|

7.7

|

9.5

|

11.8

|

14.6

|

17.9

|

21.9

|

||||||||

|

180

|

-

|

-

|

6.9

|

8.6

|

10.7

|

13.3

|

16.4

|

20.1

|

24.6

|

||||||||

|

200

|

-

|

-

|

7.7

|

9.6

|

11.9

|

14.7

|

18.2

|

22.4

|

27.4

|

||||||||

|

225

|

-

|

-

|

8.6

|

10.8

|

13.4

|

16.6

|

20.5

|

25.2

|

30.8

|

||||||||

|

250

|

-

|

-

|

9.6

|

11.9

|

14.8

|

18.4

|

22.7

|

27.9

|

34.2

|

||||||||

|

280

|

-

|

-

|

10.7

|

13.4

|

16.6

|

20.6

|

25.4

|

31.3

|

38.3

|

||||||||

|

315

|

7.7

|

9.7

|

12.1

|

15.0

|

18.7

|

23.2

|

28.6

|

35.2

|

43.1

|

||||||||

|

355

|

8.7

|

10.9

|

13.6

|

16.9

|

21.1

|

26.1

|

32.2

|

39.7

|

48.5

|

||||||||

|

400

|

9.8

|

12.3

|

15.3

|

19.1

|

23.7

|

29.4

|

36.3

|

44.7

|

54.7

|

||||||||

|

450

|

11.0

|

13.8

|

17.2

|

21.5

|

26.7

|

33.1

|

40.9

|

50.3

|

61.5

|

||||||||

|

500

|

12.3

|

15.3

|

19.1

|

23.9

|

29.7

|

36.8

|

45.4

|

55.8

|

-

|

||||||||

|

560

|

13.7

|

17.2

|

21.4

|

26.7

|

33.2

|

41.2

|

50.8

|

62.5

|

-

|

||||||||

|

630

|

15.4

|

19.3

|

24.1

|

30.0

|

37.4

|

46.3

|

57.2

|

70.3

|

-

|

||||||||

|

710

|

17.4

|

21.8

|

27.2

|

33.9

|

42.1

|

52.2

|

64.5

|

79.3

|

-

|

||||||||

|

800

|

19.6

|

24.5

|

30.6

|

38.1

|

47.4

|

58.8

|

72.6

|

89.3

|

-

|

||||||||

|

900

|

22.0

|

27.6

|

34.4

|

42.9

|

53.3

|

66.2

|

81.7

|

-

|

-

|

||||||||

|

1000

|

24.5

|

30.6

|

38.2

|

47.7

|

59.3

|

72.5

|

90.2

|

-

|

-

|

||||||||

|

1200

|

29.4

|

36.7

|

45.9

|

57.2

|

67.9

|

88.2

|

-

|

-

|

-

|

||||||||

|

1400

|

34.3

|

42.9

|

53.5

|

66.7

|

82.4

|

102.9

|

-

|

-

|

-

|

||||||||

|

1600

|

39.2

|

49.0

|

61.2

|

76.2

|

94.1

|

117.6

|

-

|

-

|

-

|

||||||||

Features:

1. Nontoxic

2. Corrosion resistance

3. No Leakage

4. Higher flow capacity than steel pipes

5. Convenient for construction and installation

6. Lower installation costs than cement and steel pipes

7. Longevity of working life more than 50 years

8. HDPE pipe can be recycled and environment-friendly

Advantages:

1. Urban potable water pipeline network system.

2. Replaceable cement pipe, iron pipe and steel pipes.

3. Fire fighting pipeline.

4. Landscaping water supply network.

5. Sewage discharge pipes.

6. Ore and mud transfers.

7. Agricultural irrigation pipe.

Product Paramenters

Physical properties index:

|

No.

|

Item

|

|

Requirements

|

|||

|

1

|

Percentage of breaking-elongation,%

|

|

≥350

|

|||

|

2

|

Longitudinal reversion(110℃),%

|

|

≤3

|

|||

|

3

|

Oxidation induction time (200℃)min

|

|

≥20

|

|||

|

4

|

Weather resistance 1. (After the pipe has accepted the aging energy which equal to or more than 3.5GJ/m2)

|

80℃ static hydraulic strength (165h)

|

No break, no leakage.

|

|||

|

|

|

Percentage of breaking-elongation,%

|

≥350

|

|||

|

|

|

Oxidation induction time (200℃)min

|

≥10

|

|||

|

1. Only suitable for pipe in blue color.

|

|

|

|

|||

|

Application field: Drinking water supply pipe for urban and rural area, liquid transmission pipe in chemical, chemical fiber,

food, forestry and metallurgy industry, waste water drainage pipe, mining slurry transmission pipe for mining field. |

|

|

|

|||

Technical data sheet:

|

No

|

Items

|

HDPE Pipe

|

|

1

|

Molecular

|

≥300 000

|

|

2

|

Density

|

0.960 g/cm3

|

|

3

|

Tensile breaking strength

|

≥28 Mpa

|

|

4

|

Longitudinal contraction rate of return

|

≤3%

|

|

5

|

Breaking elongation

|

≥500%

|

|

6

|

Resistant to corrosion

|

good

|

|

7

|

Tensile strength

|

≥28Mpa

|

|

8

|

Static hydraulic strength

|

1)20℃,cycle stress 12.4Mpa,100h,no break,no leakage

|

|

|

|

2)80℃,cycle stress5.5Mpa,165h,no break,no leakage

|

|

|

|

3)80℃,cycle stress5.0Mpa,1000h,no break,no leakage

|

|

9

|

MFR(190℃,5kg,)g/10min

|

≤25%

|

|

10

|

Oxidation induction time (200℃)min

|

≥20

|

HDPE Pipeline:

AVAILABLE IN:

• Qualities PE80 and PE100

• Pressure levels PN4 up to PN25

• Various diameters

• All lengths, up to 20 meters

HDPE WELDING COLLARS

AVAILABLE IN:

• Qualities PE80 and PE100

• Pressure levels PN4 up to PN25

• Various diameters

Manufacturing Technique

Hot Searches