- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380

-

Weight (T):

-

2 T

-

Power (kW):

-

150

-

Limit temperature::

-

2450℃

-

Leakage rate:

-

no more than 10Pa/ hour for 12 hours after pump stop for 15 minutes

-

Temperature control accuracy:

-

±11

-

Heating material:

-

graphite tube and graphite rod

Quick Details

-

Place of Origin:

-

Hunan, China

-

Marketing Type:

-

Hot Product

-

Brand Name:

-

Jingtan

-

Voltage:

-

380

-

Weight (T):

-

2 T

-

Power (kW):

-

150

-

Limit temperature::

-

2450℃

-

Leakage rate:

-

no more than 10Pa/ hour for 12 hours after pump stop for 15 minutes

-

Temperature control accuracy:

-

±11

-

Heating material:

-

graphite tube and graphite rod

Specification

Widely used in metallurgical powder, ceramic sintering, silicon carbide sintering, boron nitride sintering

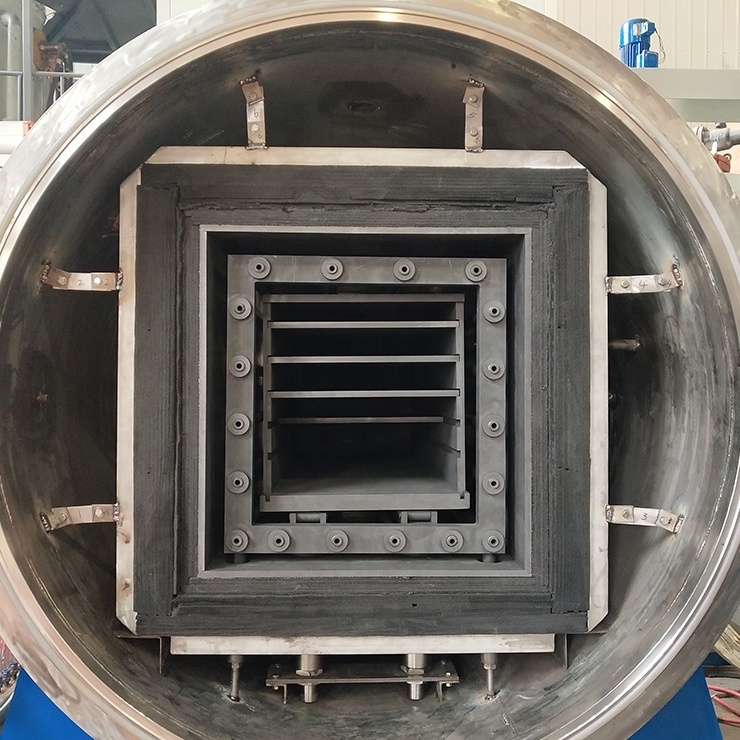

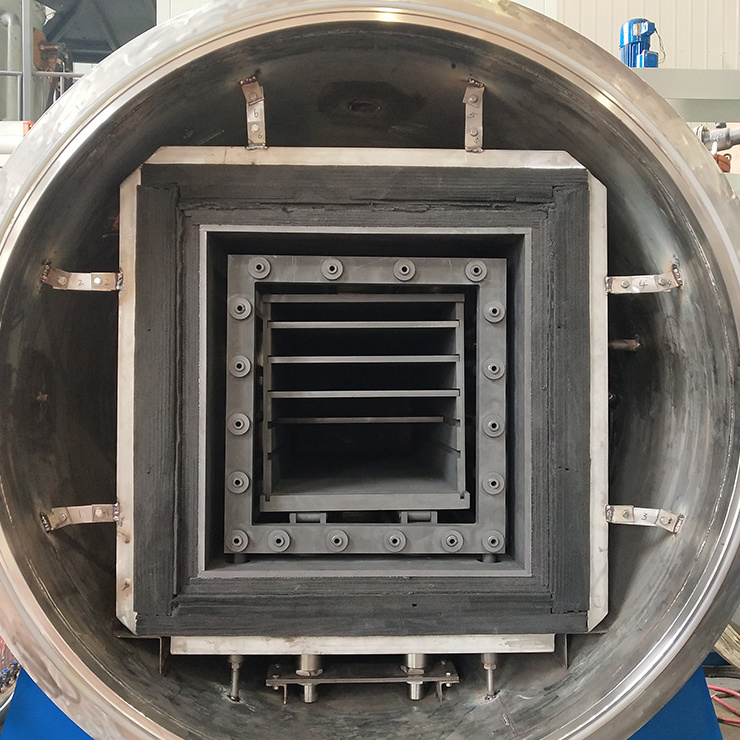

Silicon carbide sintering furnace

It is a kind of intermittent

resistance heating

furnace and

the main application scope is

non-pressure silicon carbide

sintering,

hard alloy, powder metallurgy

industry production of various particle sizes of

tungsten carbide powder,

chromium carbide powder, titanium carbide powder, vanadium carbide powder and other metal powder and composite metal powder,

cold pressing molding

,

sintering treatment.

|

Limit temperature

|

2450℃

|

|

Operating temperature

|

2300℃

|

|

Ultimate vacuum

|

1Pa(in a cold, empty and clean furnace)

|

|

Leakage rate

|

no more than 10Pa/ hour for 12 hours after pump stop for 15 minutes

|

|

Temperature control accuracy

|

±11

|

|

Voltage

|

380V、50Hz、3phase

|

|

Heating material

|

graphite tube and graphite rod

|

|

Gas supply

|

graphite tube and graphite rod

|

|

Common constant temperature area

|

300*300*500mm、400*400*800mm、 500*500*1300mm、600*600*1400mm

|

Characteristic 1:

Intelligent digital display instrument programming PID intelligent digital display temperature controller, new digital display,intelligent control technology, can reduce visual reading and human operation error, greatly improve work efficiency, double row

digital display, key setting,overtemperature alarm.

digital display, key setting,overtemperature alarm.

Characteristic 2:

Microcomputer automatic control, programmable multi-section rising, protecting, cooling curve, automatic heating, heat preservation, cooling and overtemperature protection, the program automatically stops at the end of operation, no need to watch.

Furnace adopts high temperature

durable

heat insulation material,which ensure that the temperature outside the furnace body under long-term work does not exceed the allowable value of the national standard.

Characteristic 3:

Internal circulating water system, to ensure the speed of cooling. The furnace body temperature is close to room temperature.

L Fast heating, environmental protection and energy saving, high precision, stable performance, good heat preservation effect.

Hot Searches