- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

3000*1500mm

-

Cutting Thickness:

-

0.5-22mm

-

Control Software:

-

CypCut

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

SUNDOR

-

Weight (KG):

-

4300 KG

-

Laser Source:

-

Raycus or IPG

-

Laser Power:

-

300-12000W

-

Position Accuracy:

-

≤±0.02mm

-

Wavelength:

-

1064-1080nm

-

After sales service:

-

Engineers available to service machinery overseas

-

Driving System:

-

Japanese Yaskawa Servo Motor

-

Max. Moving Speed:

-

120m/min

-

Min. Line Width:

-

≤±0.12mm

-

Showroom Location:

-

Mexico

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

0-24,000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

3000*1500mm

-

Cutting Thickness:

-

0.5-22mm

-

Control Software:

-

CypCut

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

SUNDOR

-

Weight (KG):

-

4300 KG

-

Laser Source:

-

Raycus or IPG

-

Laser Power:

-

300-12000W

-

Position Accuracy:

-

≤±0.02mm

-

Wavelength:

-

1064-1080nm

-

After sales service:

-

Engineers available to service machinery overseas

-

Driving System:

-

Japanese Yaskawa Servo Motor

-

Max. Moving Speed:

-

120m/min

-

Min. Line Width:

-

≤±0.12mm

-

Showroom Location:

-

Mexico

-

Marketing Type:

-

Hot Product 2019

Laser pipe & sheet cuttting machine

Please let's Introducing our new type of laser pipe & sheet cutting machine, which will help you to select a good laser tube & plate cutting machine: :

Why choose us?

| 1 hour quick response | Save your time and solve your worried |

| 2 year warranty | Perfect after-sales system to solve all your problems |

| C ustomized solutions | Business start from listening, OEM, ODM your application |

| W orld-brands Parts | Guarantee the equipment running stable & long working life |

| C E, ISO certification | Quality certificated by European company |

| E asy to learn & operation | Improve working effective |

Sundor laser cutting machine has the characteristics of high stability, reliable performance, simple installation and debugging, safe production and operation, complete customized functions and strong performance.

As a professional laser manufacturer, Sundor Laser could provide you with various laser cutting solutions to achieve modularization, customization, automation, and informatization.

So why wait? Contact us today to learn more about our laser cutting machine and how it can transform your business.

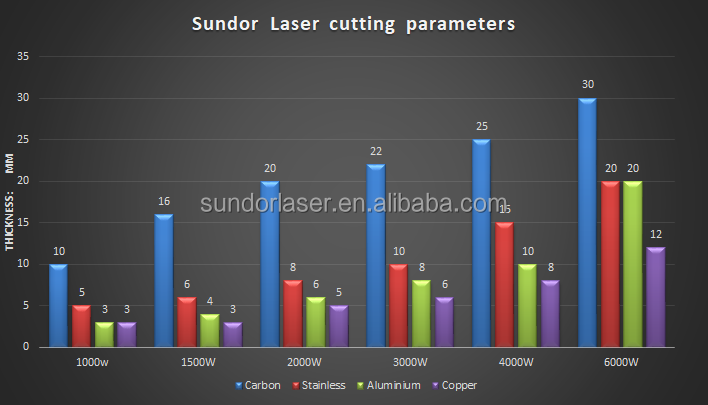

Following are some parameters of pipe & sheet laser cutting machines:

| Parameters |

Details |

|

Laser type |

Fiber laser |

|

Laser wavelength |

1064 nm |

|

Plate cutting range |

3015mm-13025mm (Any size could be custtomized) |

|

Cutting range |

Φ15-450mm |

|

Laser Power |

1000W - 30000W (optional) |

|

Beam quality |

< 0.373mrad |

| Max. Speed | 100m /min |

| Max. Acceleration | 0.6G |

|

Positioning accuracy |

±0.02mm/m |

|

Repeat positioning accuracy |

±0.02mm/m |

|

Max. Moving speed |

120m/min |

|

Support graphic format |

PLT,AI,BMP,DST , DXF format (support for CORELDRAW, AI , PHOTOSHOP, AUTOCAD ) |

|

Power Supply |

3P, AC 380V /50Hz/16A |

|

Control System |

CYPCUT |

|

Chuck |

Famous brand Pneumatic chuck |

We recommend suitable pipe laser cutting machine according to the length and outer diameter and shape of the customer's pipe.

The pipe length normally 6 meter, any length pipe laser cutting machine could be customized.

Different outer diameter of pipe suitable for different model pneumatic chuck.

Normally, standard pneumatic chuck include 160 mm, 220 mm, 350 mm etc. The max. tube diameter could reach to 450 mm. Sundor laser using famous brand pneumatic chuck, guarantee the precision of processing.

Sundor Pipe & Tube Fiber Laser Cutting Machine only accessorized several type imported & domestic famous brand laser sources to ensure the quality, stability, and long working life of our laser cutting machines.

Famous brand laser cutting head have a high-powered laser beam, that can cut through a wide range of thicknesses, ensuring smooth and clean cuts every time. Through adjustable focal length and a user-friendly interface, this tool allows for easy customization and control of the cutting process.

Japanese Fuji, Yaskawa servo motor. Guarantee the 4 axis or 5 axis laser cutting machine running smoothly and stable.

High-precision Taiwan YYC rack, Taiwan HIWIN guide rail, through advanced control system, guarantee the laser pipe cutting machine running smoothly.

QC for parts and whole equipment during the whole production and before shipment very strictly. Ensure high quality & long working life equipments sending to clients.

It is widely used for carbon steel, stainless steel, aluminum and other metal materials cutting, with high speed, high precision, high efficiency, cost-effective and energy saving. It is the first choice of the metal processing industry.

If you are looking for more information on our project, including sample photos, videos, quotes, or would like to make an inquiry, please click on the image below. Our team is available 24/7 and we would be delighted to assist you with any questions you may have.

Pipe laser cutting machines

are suitable for various types of pipes and can be used in a variety of industries for high-precision processing. These machines are commonly used in industries such as automotive, aerospace, and manufacturing, as well as construction and other related fields.

Application Materials:

Laser cutting machine is suitable for all kinds of metal sheets, pipes (with special devices), stainless steel, carbon steel, galvanized sheet, pickled sheet, brass sheet, brass sheet, bronze sheet, aluminum sheet, manganese steel, gold-plated, silver-plated , titanium plates, various alloy plates, rare metals, etc.

Different materials and thickness suitable for different power laser souce.

Contact us, let's show you more details of laser cutting technology.

Welcome to contact us at any time, we could show you more cutting parameters.

Packing:Equipment loading into container by plastic film covering.

Installation & training:

Upon the machine’s arrival at the buyer’s site, the seller’s engineers will be responsible for installation and commissioning of the machine using special tools, with the assistance of the buyer. The buyer is responsible for covering the costs of the engineer’s visa, airfare, lodging, and meals.

Training:

Our comprehensive training program covers essential laser safety knowledge, including precautions and protective measures.

We also provide training on the basic principles of laser modules and the structure of a laser cutting machine, as well as hands-on operation skills specifically for fiber laser cutting machines.

Topics covered during training include equipment operation, application notice, daily maintenance skills, laser module adjustment techniques, and spare parts replacement.

The installation and training program typically lasts between 2 to 7 days, depending on specific requirements. Very easy to learn and operation.

Warranty & Service:

1). 2 year s warranty for the whole machine

2). 2 years warranty for the fiber laser source

3). Life-long maintenance

4) During the warranty period, in case of breakdown or parts damage (except for human factors and force majeure), the seller will take responsibility for free repairs, and provide free replacement parts (except for quick-wear parts).

5) After the warranty period, we still offer lifetime maintenance service free of charge, with parts replacement being charged.

6) Our after-sales service department guarantees a quick response within 8 working hours of receiving repair calls. Our experienced after-sales engineer will reply as soon as possible to ensure prompt resolution of any issues.

Why SUNDOR Laser

FAQ for Laser Cutting Machine:

Q1: I know nothing about this machine, what type of machine should I choose?

We will help you choose the suitable machine and share you the solution; you can share us what material will you cut, the material thickness and working size.

Q2: When I got this machine, but I don’t know how to use it. What should I do?

We will send English manual and Operation Video and for the machine. Our engineer will do training online. If needed, we can send our engineer to your site for training or you can send the operator to our factory for training.

Q3: May we know the speed of your Fiber Laser Cutting Machine as per on our demand basis?

We use Japan Servo motor and driver with big strength, so the max moving speed can reach 120m/min, max cutting speed can reach 40m/min. And the speed can reach 1.5-2m/min if you cut 4.5-5mm stainless steel.

Q4: If some problems happen to this machine, what should I do?

We provide two years machine warranty. During the two-year warranty, in case any problem for the machine, we will provide the parts free of charge (except for artificial damage). After the warranty, we still provide whole lifetime service. So any doubts, just let us know, we will give you solutions.

Q5: About accuracy, we have observed that after some time "Machine accuracy can increase gradually" and after long time, the difference reach to its maximum level. How about your machine?

The frame of the machine is annealed, it can support shock resistance(the machine will deform if without annealing ). So the accuracy of the machine can keep its original accuracy for 4-5years. The weight of the machine can reach 4.5t-5.0t. It also can let the machine have higher accuracy and higher stability.

Q6: What’s package, will it protect the products?

A: Nude Packing for big parts after plastic film covering. The small parts packed into wooden cases which is suitable for seaworthy transportation.

Q7: How is the shipping method?

A: As per your actual address, we can effect shipment by sea, by air, by truck or railway. Also we can send the machine to your worksite as per your requirement .