- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Inconel718

-

Shape:

-

Pipe

-

Material:

-

Nickel alloy

-

Chemical Composition:

-

Nickel alloy

-

Product name:

-

718 Alloy Welded Pipe

-

Purity:

-

High Purity

-

Usage:

-

Widely

-

Size:

-

Customers' Requirements

-

Color:

-

Sliver

-

MOQ:

-

1kg

-

Type:

-

Non Ferrous Metal Material

-

Packing:

-

Wooden Packing

-

Weight:

-

Actual Weight

-

Sample:

-

Support Sample Service

Quick Details

-

Application:

-

Welding

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Chuanmao

-

Model Number:

-

Inconel718

-

Shape:

-

Pipe

-

Material:

-

Nickel alloy

-

Chemical Composition:

-

Nickel alloy

-

Product name:

-

718 Alloy Welded Pipe

-

Purity:

-

High Purity

-

Usage:

-

Widely

-

Size:

-

Customers' Requirements

-

Color:

-

Sliver

-

MOQ:

-

1kg

-

Type:

-

Non Ferrous Metal Material

-

Packing:

-

Wooden Packing

-

Weight:

-

Actual Weight

-

Sample:

-

Support Sample Service

Product Description

|

Material

|

Nickel alloy

|

|

Standard

|

ASTM B983

|

|

Grade

|

INCONEL 718

|

|

Brade

|

PYE

|

|

Size

|

O.D 6-219mm; W.T:1-30mm

|

|

Chemical composition

|

Ni: 50~55% ; Cr:17~21% ; Fe: balance;Mo:2.8~3.3% ; Nb: 4.75~5.5% ; Co: ≤1.0% ; C≤0.08% ; Mn≤0.35% ; Si≤ 0.35% ; Cu≤0.3% ; Al:

0.2~0.8% ; Ti: 0.65~1.15% ; P≤0.015% ; |

|

Density

|

8.24 g/cm3

|

|

Melting range

|

1260~1340℃

|

|

Characteristic as below

|

1.workability

2.High tensile strength,endurance strength,creep strength and rupture strength at 700℃. 3.High inoxidability at1000℃. 4.Steady mechanical performance in the low temperature. 5.Good welding performance. |

|

Metallurgical structure

|

718 alloy is Austenitic structure, precipitation hardening generate "γ" made it excellent mechanical performance. G rain boundary

generate "δ" made it the best plasticity in the heat treatment. |

|

Corrosion resistance

|

718 alloy with extremely resistance to stress corrosion cracking and pitting ability in high temperature or low temperature

environments, especially the inoxidability in the high temperature. |

|

Application field

|

The elevated temperature strength, excellent corrosion resistance and workability at 700℃ properties made it use in a wide range

of high requirement environments. 1.Steam turbine 2.Liquid-fuel rocket 3.Cryogenic engineering 4.Acid environment 5.Nuclear engineering |

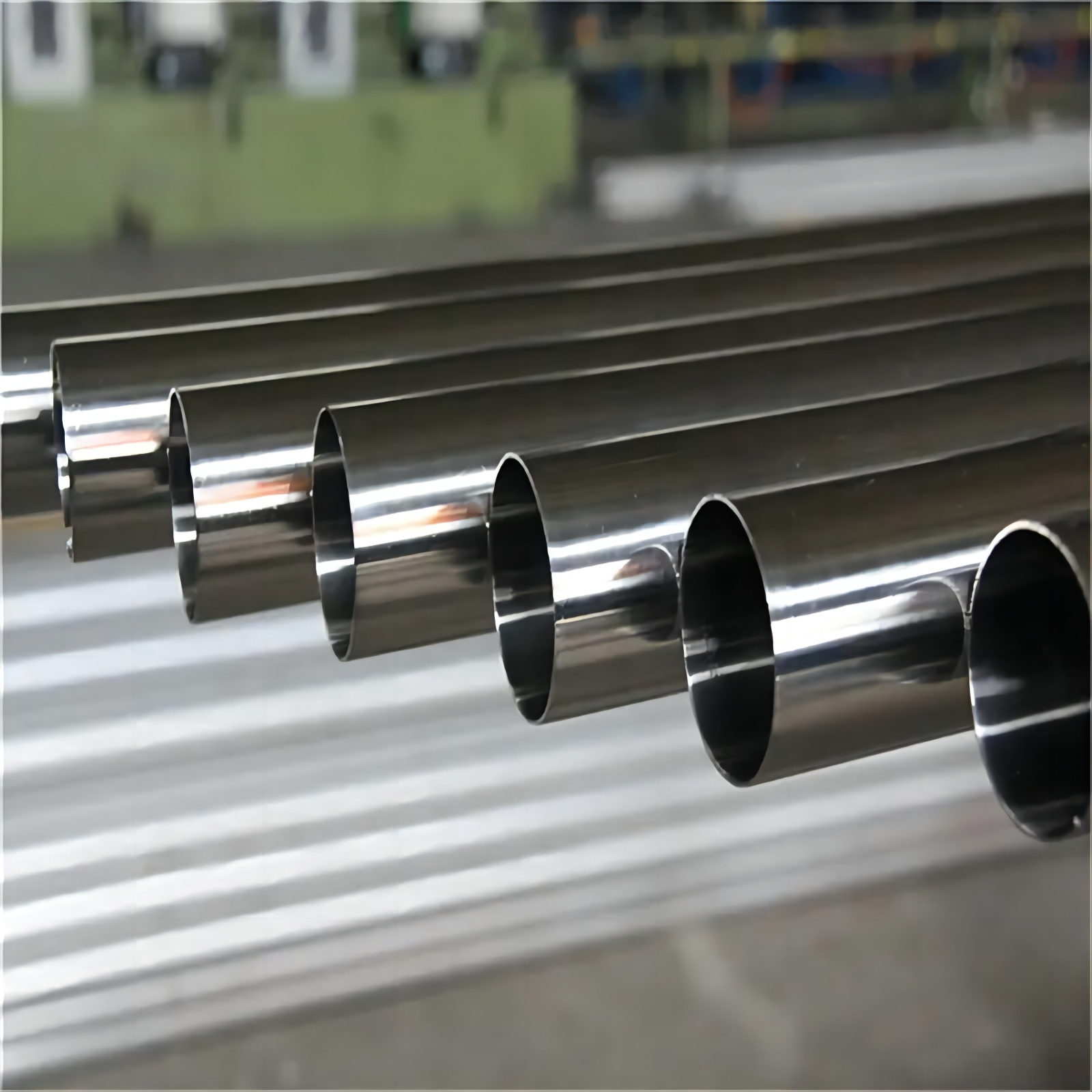

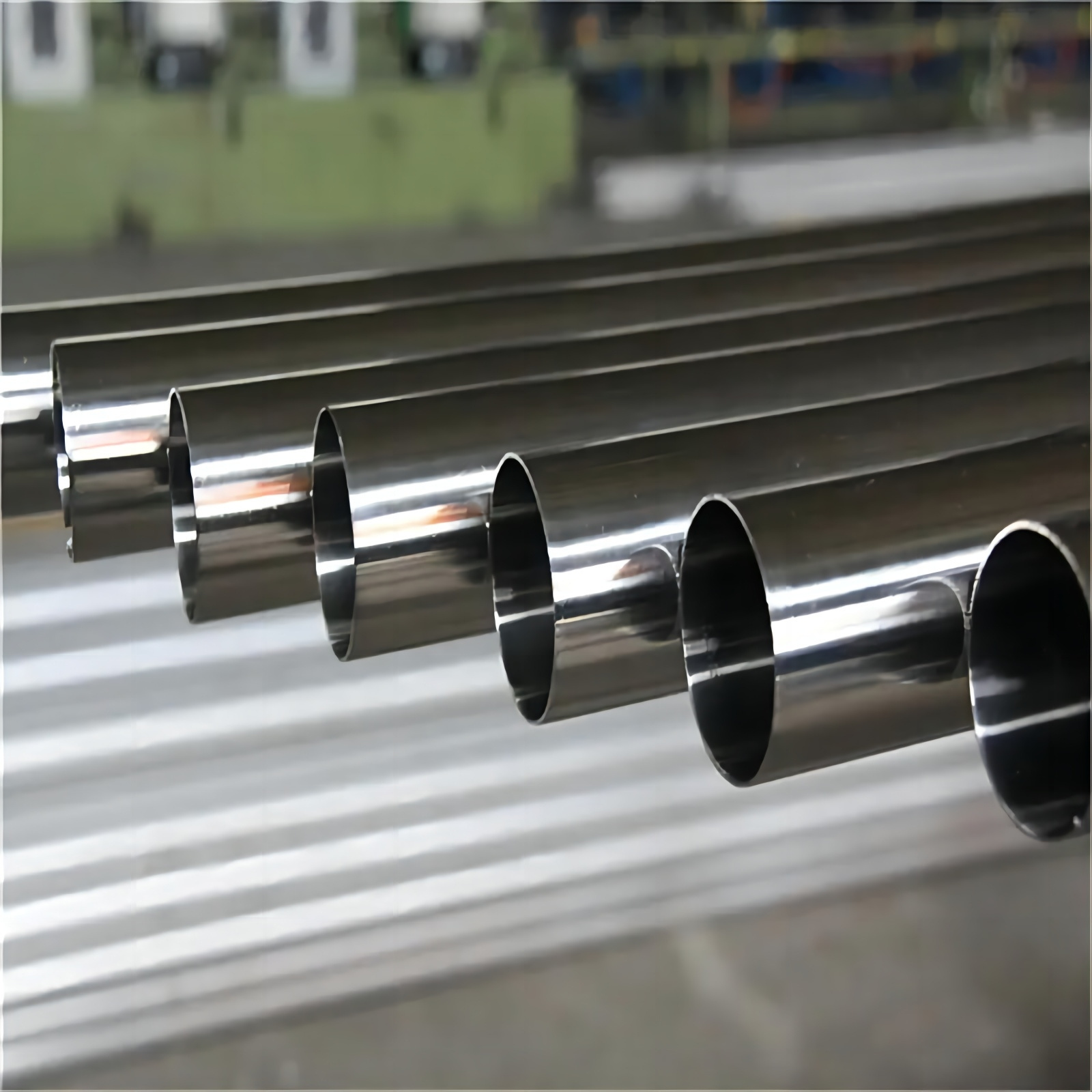

Detailed Images

Buyer evaluation

Hot Searches