- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JC03-01

-

Keyword:

-

Mould Maker

-

Product materials:

-

PDCPD

-

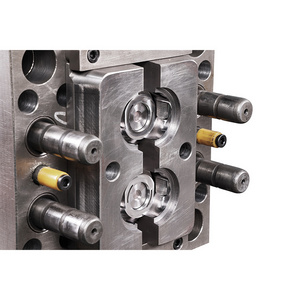

Mould material:

-

Aluminium/Steel Mold

-

Mould Life:

-

5000-100000 shots

-

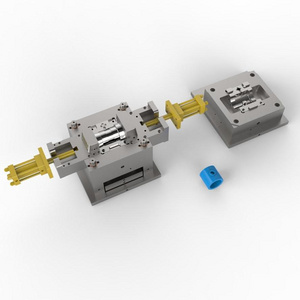

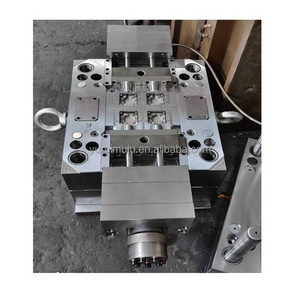

Mould type:

-

Reaction Injection Moulding(RIM)

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Surface treatment:

-

Painting

-

Design:

-

3D CAD STP OEM ODM

-

Size:

-

Customized Size

-

Service:

-

24 Hours Service

Quick Details

-

Shaping Mode:

-

Reaction Injection Moulding

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jingchuang

-

Model Number:

-

JC03-01

-

Keyword:

-

Mould Maker

-

Product materials:

-

PDCPD

-

Mould material:

-

Aluminium/Steel Mold

-

Mould Life:

-

5000-100000 shots

-

Mould type:

-

Reaction Injection Moulding(RIM)

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Surface treatment:

-

Painting

-

Design:

-

3D CAD STP OEM ODM

-

Size:

-

Customized Size

-

Service:

-

24 Hours Service

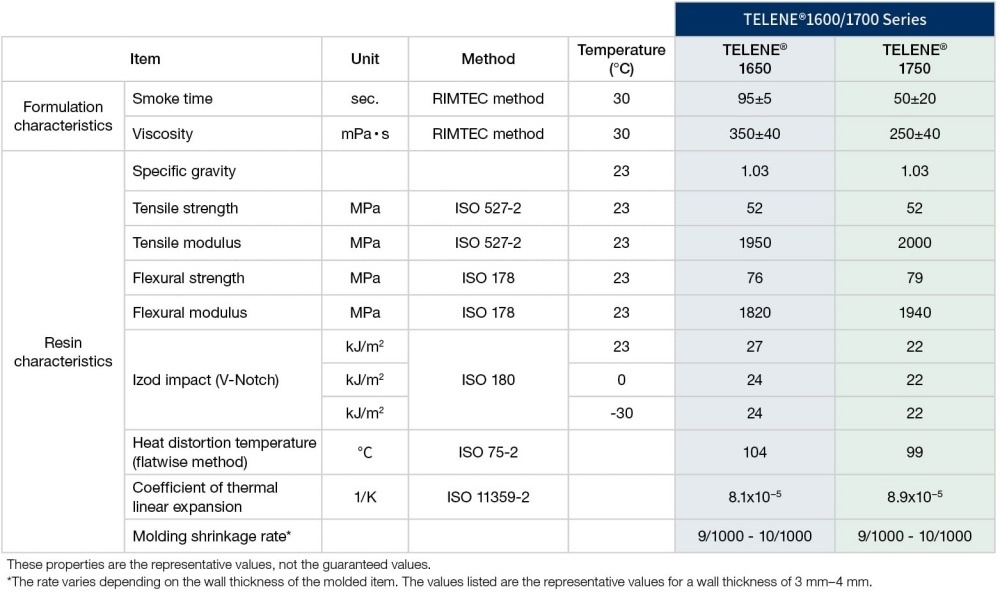

PDCPD products are used in truck side trim panels, step boards, bumpers, integral cowl, baffle, etc., 1.03g/mm3 density to achieve the goal of lightweight, a single size can complete 4m products, with high design freedom, strong impact resistance and good rigidity, can well reflect the design intention; Excellent installation structure, easy to assemble, to ensure higher assembly quality; At the same time, large products than traditional injection molding process, mold development costs can be greatly reduced, more suitable for small and medium-sized batches, such as new energy

heavy truck; Low temperature resistance of -40 degrees Celsius, it can also be used in cold areas of the northern hemisphere.

Hot Searches