- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GUANYOU

-

Dimension(L*W*H):

-

2050*1600*1800(MM)

-

Weight:

-

2500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Can height(mm):

-

50-250

-

Can diameter (mm):

-

52-165

-

After Warranty Service:

-

Spare parts

-

Marketing Type:

-

New Product 2023

-

Power:

-

6kw

-

Function:

-

Produce Fruit Cans

Quick Details

-

Application:

-

Food, Beverage

-

Packaging Material:

-

Metal

-

Voltage:

-

220V/380V/440V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GUANYOU

-

Dimension(L*W*H):

-

2050*1600*1800(MM)

-

Weight:

-

2500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Can height(mm):

-

50-250

-

Can diameter (mm):

-

52-165

-

After Warranty Service:

-

Spare parts

-

Marketing Type:

-

New Product 2023

-

Power:

-

6kw

-

Function:

-

Produce Fruit Cans

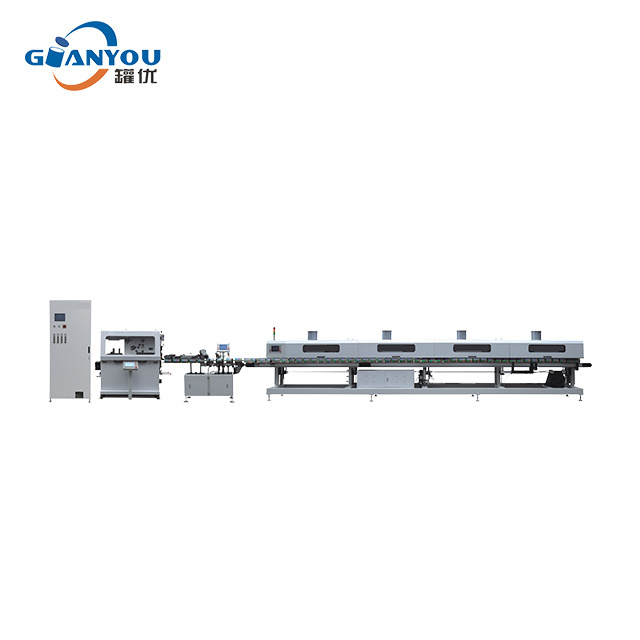

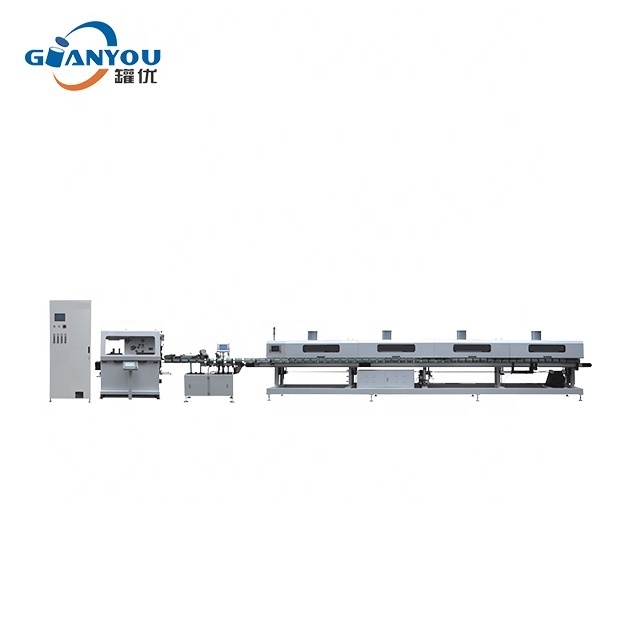

Ketchup cans tomato paste tin can making machine automatic food cans production line

|

Item NO.: |

000000 |

Product Name: |

machine production |

|

G.W./N.W. |

27000/26000 |

Product Size: |

17000*2000*3050cm |

|

CTN Size: |

17000*2000*3050 cm |

MOQ: |

1 set |

|

Package: |

wooden box/film |

Measurement: |

103.7cbm |

|

Color: |

blue&orange |

Delivery time |

25-40 days for OEM |

Product Features:

1.Process:orientation/expanding/panelling/top flanging and bottom flanging/bottom seaming/turning/top seaming

2.Automatic control system with servo motor control

3.touch panel man-machine interface

4.convenient operation and adjustment

5.High production efficiency

6.Production capacity(cans/min)30

7.Air pressure(mpa):0.3-0.5 9.Motor power(kw)43

|

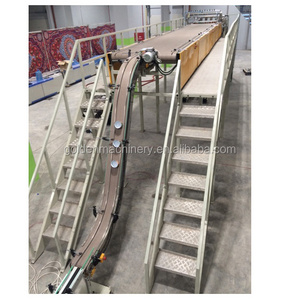

Description : |

Automatic welding machine(300cpm) |

Capacity : |

200-320cpm |

|

G.W./N.W. |

2510 / 2500 |

Product Size: |

2050 * 16 00* 180 0 m m |

|

CTN Size: |

2050 * 16 00* 180 0 m m |

MOQ: |

1 set |

|

Package: |

wooden box/film |

Automatic/Semi-auto : |

Automatic |

|

Color: |

blue&orange |

Delivery time |

25-40 days for OEM |

1.Plate thickness(mm): 0.16-0.38

2.Copper wire (mm): 1.38-1.5

3Welding speed(m/min): 45

4.It adopts Japan Omron and French Schneider electrical control,equiping with SMC pheumetic parts.

5. The material of roller is imported from Europe,so it ensures high precesion between each part, minimum reject rate,smooth production.

6.Three individual servo motor: adjustable on touch panel , easy to control and operate and high precision