- Product Details

- {{item.text}}

Quick Details

-

Name:

-

2205 duplex stainless steel investment casting parts

-

Material:

-

2205 duplex/304/316/carbon steel

-

Application:

-

Industry

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Service:

-

Drawing Custom

-

Certification:

-

ISO9001: 2008

-

Package:

-

Woodencase

-

Tolerance:

-

0.01mm

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HYRH

-

Model Number:

-

Customized

-

Name:

-

2205 duplex stainless steel investment casting parts

-

Material:

-

2205 duplex/304/316/carbon steel

-

Application:

-

Industry

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Service:

-

Drawing Custom

-

Certification:

-

ISO9001: 2008

-

Package:

-

Woodencase

-

Tolerance:

-

0.01mm

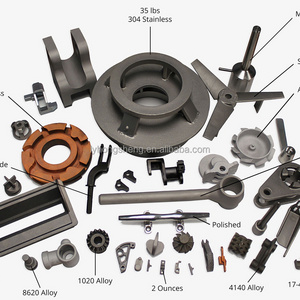

Product Name:2205 duplex 304 316 precision stainless steel investment casting parts lost wax casting

Assembly parts:

What is Stainless Steel Casting?

Stainless steel casting is the investment casting process throught pouring melton stainless steel into moulds for solidification, thus to achieve a solid stainless steel component in a desired shape.

Stainless steel casting is considered where both the properties of steel and corrosion resistance are required. So like other cast steel alloys, stainless steel is widely used material for casting production.

Common Material Grades of Stainless Steel Casting

| 304 | The most widely used austenite steel, may be referred to as A2 stainless. |

| 304L | This grade has slightly lower mechanical properties than the standard 304 grade, but is still widely used in casting for its versatility |

| 316 | The second most common austenite steel, also referred to as A4 stainless. SS316 is used primarily for its increased resistance to corrosion. |

| 316L | Lower carbon content than 316 stainless steel, which reduces the sensitization effect caused by the high temperatures involved in welding. Besides, it shows better resistance to stress-corrosion cracking. |

| 17-4 PH | Most common precipitation-hardening martensitic stainless steel, which uses about 17% chromium and 4% nickel. |

| 2205 Duplex | Used for its good mechanical properties and excellent corrosion resistance properties. |

|

Product Name |

2205 duplex 304 316 precision stainless steel investment casting parts lost wax casting |

| Product Type: | Casting,CNC turning, milling, drilling,grinding,cutting. |

| Material: | 304/316/2205/316l/904l stainless steel , carbon steel,alloy steel |

| Surface Treatment: | Anodizing,Sandblasting, Painting,Powder coating, Plating,Polishing |

| Dimension: | As per customer's drawing |

| Drawing Format: | Pro-E/UG/Solid Works |

| Testing Machine: | Digital Height Gauge,Caliper, Coordinate measuring,projection machine,CMM |

| Packing: | PP bag/EPE Foam/Carbon boxes/ plywood case |

| Trial sample: | 10-15 days after sample confirmation. |

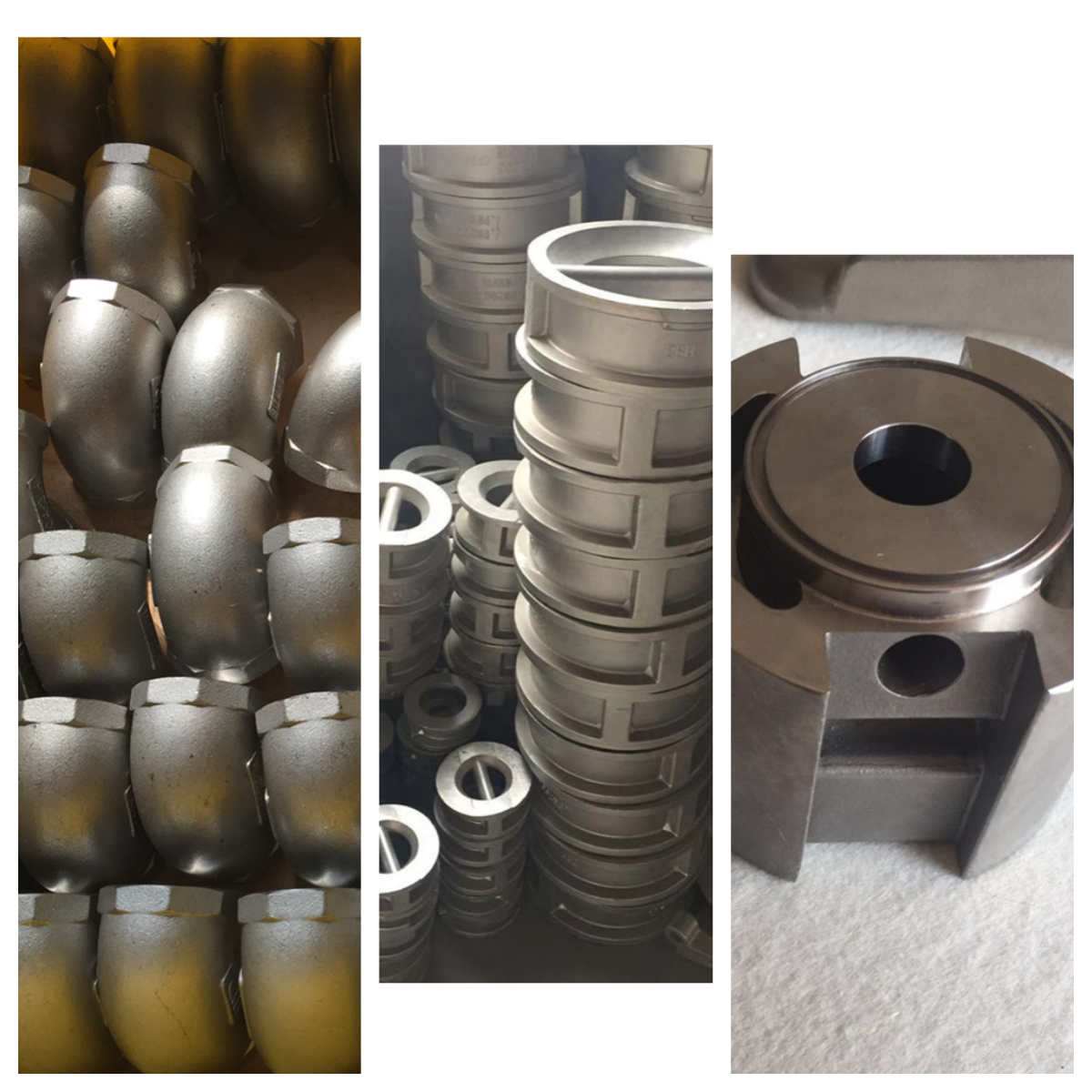

Workshop Workshop

Workshop Workshop

Workshop Workshop

Why Choose HYRH for your Investment Castings?

Quality Assurance

Investment casting from our foundry must go throught a district quality inspection process. With ISO 9001:2008 certificated and rich casting experience, we are always getting good reputation from our customers all over the world.

Shot Lead time

Maybe you ever waited months to receive your castings. At CFS foundry, we can have your investment castings delivered within 30 working days. In addtions, our goal is 100% on-time delivery. We work closly with you to guarantee projects move along from design to delivery as fast as we can.

Wide Alloy Selection

Here, you will not need to worry if we can supply the alloys you need, we can make steel casting , iron casting , as well as aluminum casting . Just pls provide the alloy specifications or compositions. We can make accordingly.

Low cost

Investment casting may seem more expensive than drop forging methods, but it also requires less secondary machining. HYRH focuses on creating quality investment cast products, and can turn multiple piece projects into single piece projects. We think outside the box to create smarter and more efficient castings.

Material Testing

Chemical composition is the basic property of a metal cast part, which will directly affect the mechanical properties of products. So during investment casting process, material testing is a vital step for obtaining qualified products.

X-Ray Testing of Castings