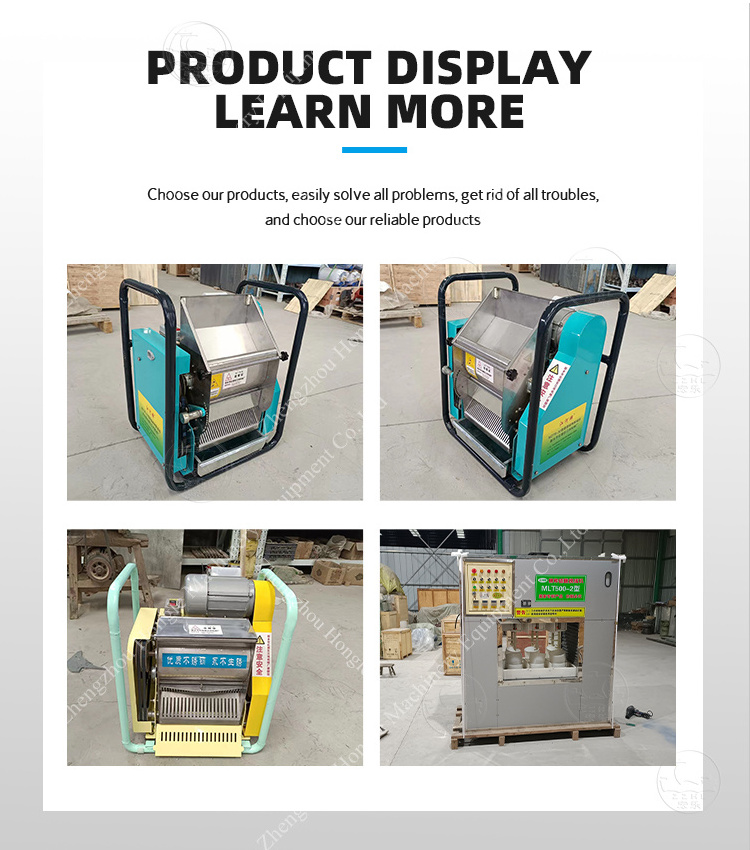

Scope of application:

machine-picked cotton, re-picked cotton, ground cotton, artificial fast-picked cotton.

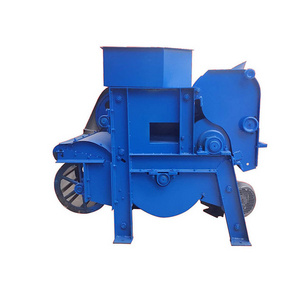

Moisture drying

is the process of evaporating moisture by using heat source under the action of mechanical force. Complementing this is the natural drying of seed cotton.

Capacity :Customize your quotation plan according to your finished product and output requirements.