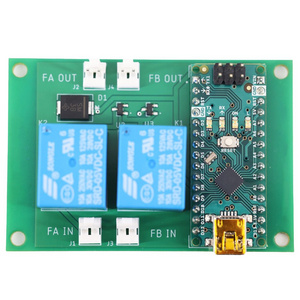

• IQC

• automatic solder paste printing

• SPI

• SMT

• Reflow soldering

• AOI • X-RAY (for BGA)

• ICT testing

• DIP through hole

• Wave soldering

• board cleaning

• Firmware Programming

• Function Testing

Explore More Products

- Product Details

- {{item.text}}

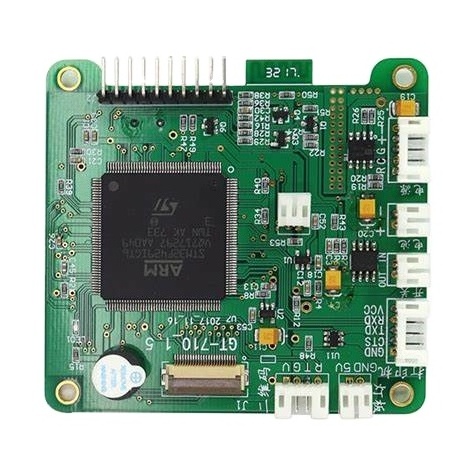

Quick Details

-

Brand Name:

-

Customization

-

Supplier Type:

-

OEM/ODM

-

Certificate:

-

ISO9001/CE/ROHS

-

MOQ:

-

1 PCS

-

PCB Standard:

-

IPC-A-610 D/IPC-III Standard

-

Product name:

-

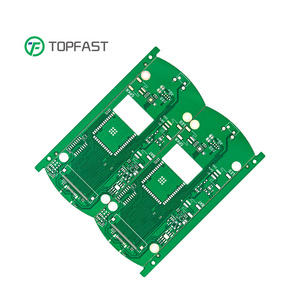

PCBA Board Assembly

-

Application:

-

Electronics Device

-

Surface Finishing:

-

HASL

-

Service:

-

One-stop Turnkey

-

Base Material:

-

FR-4

-

Solder mask color:

-

Blue.green.red.black.white.etc

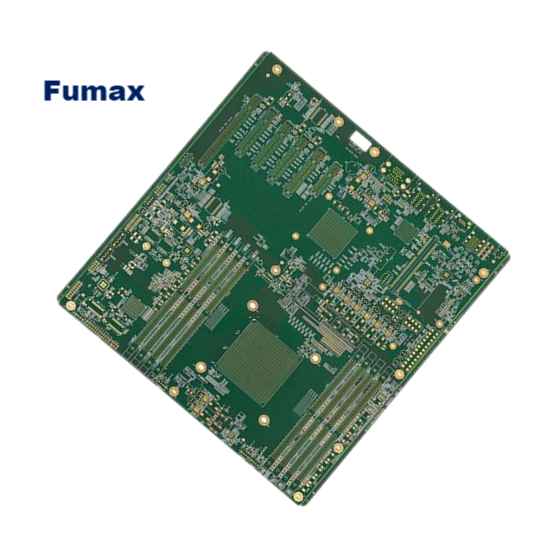

Quick Details

-

Model Number:

-

Fumax-US

-

Type:

-

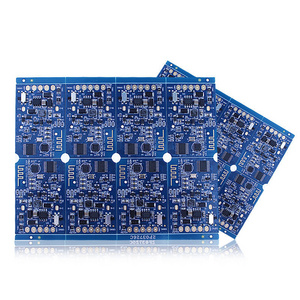

Multilayer pcb

-

Place of Origin:

-

GUA

-

Brand Name:

-

Customization

-

Supplier Type:

-

OEM/ODM

-

Certificate:

-

ISO9001/CE/ROHS

-

MOQ:

-

1 PCS

-

PCB Standard:

-

IPC-A-610 D/IPC-III Standard

-

Product name:

-

PCBA Board Assembly

-

Application:

-

Electronics Device

-

Surface Finishing:

-

HASL

-

Service:

-

One-stop Turnkey

-

Base Material:

-

FR-4

-

Solder mask color:

-

Blue.green.red.black.white.etc

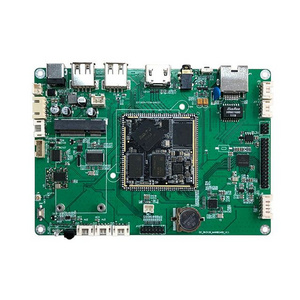

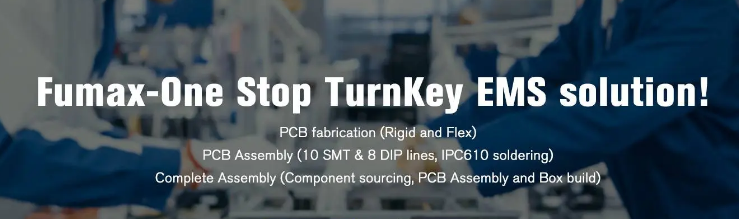

Our Main Services

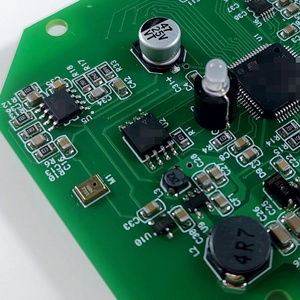

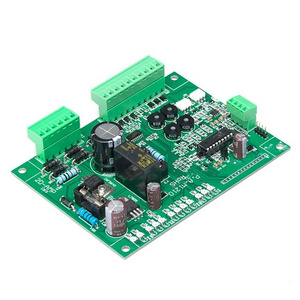

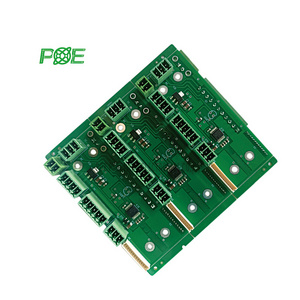

PCBA (Pcb Assembly)

Production Capability

|

Model Number: PCB/PCB Assembly

|

Model Number: PCB/PCB Assembly

|

|

Supplier Type: OEM/ODM/Customized

|

Layer:1-20

|

|

Board Thickness:0.20mm-4.0mm

|

Copper Thickness:17.5um-175um (0.5oz-5oz)

|

|

Solder mask color: red, black, blue, green, yellow

|

Frequency of stencil cleaning:1 time/5 to 10 pieces

|

|

Surface Treatment: HASL, Lead free HASL, OSP, Gold Plating, Immersion gold

|

Min Trace Width: 0.15mm

|

|

Min. Line Spacing:3 mil (0.075 mm)

|

Min Space Width: 0.15mm

|

|

Base Material: FR4/CEM-1/CEM-3/Aluminium

|

Min Drilling Dia: 0.2mm

|

Factory equipment

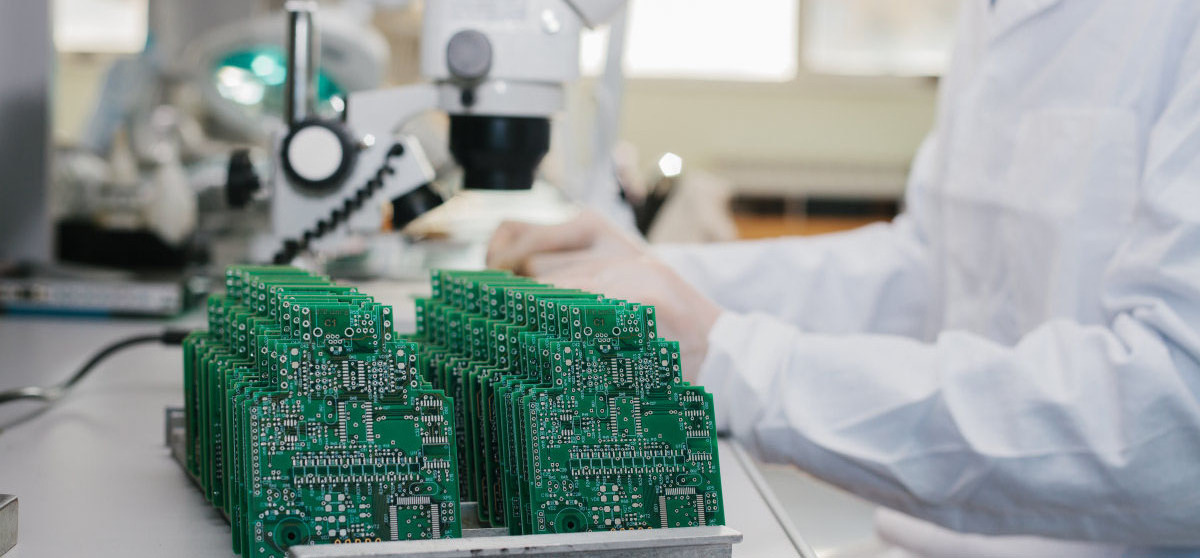

AOI Quality Check

Wave Soldering M

achine

Reflow Soldering Machine

SMT Machine 1

SMT Machine 2

Magnifier

4 SMT Line

Solder Paste Printing Machine 1

Solder Paste Printing Machine 2

Our Certificate

Quality Control

IQC

In Fumax, all materials must be verified and approved before

going to the warehouse. Fumax Tech establishes strict verifying procedures and working instructions to control the incoming.

AOI

AOI is a very important QC process of checking SMT soldering quality.

Fumax has strict control on AOI. ALL 100% boards are checked by AOI machine at Fumax SMT line.

Fumax has strict control on AOI. ALL 100% boards are checked by AOI machine at Fumax SMT line.

ICT

ICT mainly checks the single components on the line and the open and short circuit of each circuit network. Fumax will build ICT for each board to test board connection and functions.

Customer Visits

Deliver

All our products are packed in anti-static packaging+customized part(if any)

FAQ

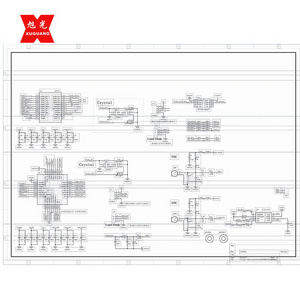

Q.What kind of documents/files do you need for quotation?

For PCBA project, please send us your Gerber

files, BOM(bill of material),and pcb specification.

For plastic enclosure/junction box/shell, please send us your 3D drawing,and material.

For ODM/Engineer Development service, please consult our sales engineer for more details.

Q. How to keep our product information and design file secret ?

We are willing to sign a NDA effect by customers side local law and promising tokeep customers data in high confidential level.

Q.How long does it take for PCB and PCBA Quote?

*Please note that the following detail will speed up evaluation:

Material:

Board thickness:

Copper thickness:Surface finish:

Solder mask color:

Silkscreen color:

Q.How can we guarantee you receive an good quality product?

For PCB, we will use Flying Probe Test, E-test etc. for it.

For PCBA, we need you to offer us a method or test fixture for the function test.Before that, our inspectors will use microscope and X-ray to check the IC footwelding or bad solder etc.

For ODM/Engineer Development service, please consult our sales engineer for more details.

Q. How to keep our product information and design file secret ?

We are willing to sign a NDA effect by customers side local law and promising tokeep customers data in high confidential level.

Q.How long does it take for PCB and PCBA Quote?

*Please note that the following detail will speed up evaluation:

Material:

Board thickness:

Copper thickness:Surface finish:

Solder mask color:

Silkscreen color:

Q.How can we guarantee you receive an good quality product?

For PCB, we will use Flying Probe Test, E-test etc. for it.

For PCBA, we need you to offer us a method or test fixture for the function test.Before that, our inspectors will use microscope and X-ray to check the IC footwelding or bad solder etc.

Hot Searches