- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

32

-

Place of Origin:

-

Hebei, China

-

Application:

-

Battery

-

Grade:

-

Nickel

-

Ni (Min):

-

99.5%

-

Model Number:

-

Ni200,Ni201

-

Brand Name:

-

CHY

-

GB standard:

-

GB/T 2072-2007

-

GOST standard:

-

GOST 492-2006

-

Surface:

-

Bright

-

Size:

-

Customized Size

-

Density:

-

8.9g/cm3

-

Material:

-

pure nickel

-

Technique:

-

Hot Rolled Cold Drawn

-

Keyword:

-

nickel wire pure 0.025mm

-

Feature:

-

high purity

Quick Details

-

Resistance (μΩ.m):

-

0.087 μOhm*m

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

390

-

Elongation (≥ %):

-

32

-

Place of Origin:

-

Hebei, China

-

Application:

-

Battery

-

Grade:

-

Nickel

-

Ni (Min):

-

99.5%

-

Model Number:

-

Ni200,Ni201

-

Brand Name:

-

CHY

-

GB standard:

-

GB/T 2072-2007

-

GOST standard:

-

GOST 492-2006

-

Surface:

-

Bright

-

Size:

-

Customized Size

-

Density:

-

8.9g/cm3

-

Material:

-

pure nickel

-

Technique:

-

Hot Rolled Cold Drawn

-

Keyword:

-

nickel wire pure 0.025mm

-

Feature:

-

high purity

Product Paramenters

Chemical composition%

|

Grade

|

Ni+Co

|

As

|

Bi

|

C

|

Cd

|

Cu

|

Fe

|

Mg

|

Mn

|

|

Ni201

Ni200

|

≥99,9

≥99,5 |

≤0,001

≤0,002 |

≤0,001

≤0,02 |

≤0,01

≤0,1 |

≤0,001

≤0,002 |

≤0,015

≤0,1 |

≤0,04

≤0,1 |

≤0,01

≤0,1 |

≤0,002

≤0,05 |

|

|

P

|

Pb

|

S

|

Sb

|

Si

|

Sn

|

Zn

|

Impurity

|

|

|

Ni201

Ni200

|

≤0,001

≤0,002 |

≤0,001

≤0,002 |

≤0,001

≤0,005 |

≤0,001

≤0,002 |

≤0,03

≤0,15 |

≤0,001

≤0,002 |

≤0,005

≤0,007 |

≤0,1

≤0,5 |

|

Physical properties

|

Alloy grade

|

Density

|

Melting point

|

Thermal conductivity

|

Specific heat capacity

|

Elastic Modulus

|

Resistivity

|

|

|

g/cm

3

|

℃

|

λ/(W/m•℃)

|

J/kg•℃

|

GPa

|

μΩ•m

|

|

Ni201

|

8.89

|

1435-1446

|

79.3

|

456

|

205

|

0.085

|

|

Ni200

|

8.89

|

1435-1446

|

70.2

|

456

|

205

|

0.096

|

Mechanical properties

|

Material condition

|

Tensile strength,

Mpa (kgf / mm

2

), not less than, grades

|

elongation,

% not less than

grades

|

|

|

|

|

Ni201; Ni200

|

Ni201; Ni200

|

|

|

|

|

|

δ

10

|

δ

5

|

|

|

Soft

|

390 ( 40)

|

32

|

35

|

|

|

1/2 Hard

|

440 ( 45)

|

10

|

12

|

|

|

Hard

|

540 ( 55)

|

2

|

3

|

|

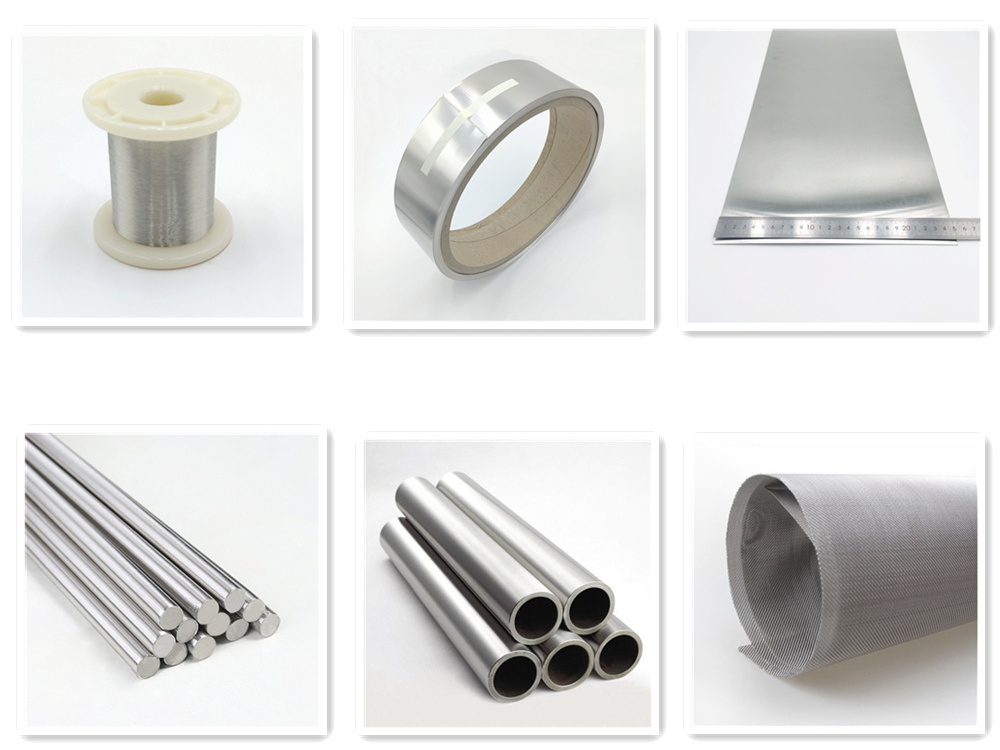

Supply form and specification

|

Alloy grade

|

Form

|

Specification

|

|

|

|

Ni201/Ni200

|

Wire

|

Diameter=0.025mm~8mm

|

|

|

|

Ni201/Ni200

|

Flat wire

|

Width=0.4~40mm

|

Thick=0.03~2.9mm

|

|

|

Ni201/Ni200

|

Strip

|

Width=1~250mm

|

Thick=0.05~3.0mm

|

|

|

Ni201/Ni200

|

Foil

|

Width=5~120mm

|

Thick=0.001~3mm

|

|

|

Ni201/Ni200

|

Bar

|

Diameter=3~100mm

|

Length=50~1000

|

|

|

Ni201/Ni200

|

Plate

|

Thickness :1mm~50mm;Width:50mm~1000mm

Length:500mm~6000mm |

|

|

Product Description

Ni201

pure nickel is a pure nickel grade with extremely low carbon content. It has been used to serve high temperature environments up to 1230 °C. It has excellent corrosion resistance to caustic soda, chlorine, etc. In particular, it is used in the material environment of diaphragm electrolytic caustic soda production equipment. Similar grades of Ni201 are Alloy 201, N02201, 2.4068, Nickel 201. Ni201 nickel wire has good mechanical strength, corrosion resistance and high heat resistance, and is suitable for making vacuum devices, electronic instrument components, and filters for chemical production of strong alkalis. Ni201 pure nickel product is suitable for radio, electric light source, machinery manufacturing, chemical industry, and is an important structural material in vacuum electronic devices.

Ni200

pure nickel alloy has a slightly lower nickel content than Ni201, in which the content of Ni and Co is greater than 99.5%, and the content of other impurities is not higher than 0.5%. Ni200 has the characteristics of acid and alkali resistance, especially its outstanding alkali corrosion resistance. It has excellent alkali and neutral solution medium for carbonate, nitrate, sulfate, chloride and acetate salt Corrosion resistance, stable performance in atmosphere, fresh water and sea water. At the same time, it also has good processing performance and high electric vacuum performance. Therefore, Ni200 is widely used in chemical, chemical, mechanical and electronic industries, and is mainly used to make various alkali-resistant equipment.

Nickel wire, strip, bar, plate are most often used in instrumentation, mechanical engineering, radio engineering, electronics, batteries and household appliances.

The main advantages of nickel rolling:

• High corrosion resistance;

• Resistance to work in hostile environment.

• Stability in work at high temperatures;

• High strength;

• Durability;

Due to its stable operation at high temperatures, nickel wire and strip are indispensable for production in the manufacture of electronic devices, navigation devices and high-precision electrical engineering.Cheng Yuan produces nickel wire, strip, bar and sheet of hard and soft state (depending on alloy grade).Our company is characterized by a flexible pricing system and an individual approach to each client.To clarify the technical characteristics, the possibility of manufacturing products, their cost and delivery conditions, you can contact our managers.

please contact us if you have any needs about 0.025mm pure nickel wire, we will give you good quality products and competitive price.

Recommend Products

Classification

Hot Searches