- Product Details

- {{item.text}}

Quick Details

-

Max Sewing Thickness:

-

30mm

-

Voltage:

-

220V

-

Power:

-

1800-2500W

-

Dimension(L*W*H):

-

1200*600*1200MM

-

Weight:

-

80 KG

-

After-sales Service:

-

Video technical support

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE

Quick Details

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Shiding

-

Max Sewing Thickness:

-

30mm

-

Voltage:

-

220V

-

Power:

-

1800-2500W

-

Dimension(L*W*H):

-

1200*600*1200MM

-

Weight:

-

80 KG

-

After-sales Service:

-

Video technical support

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE

Product Description

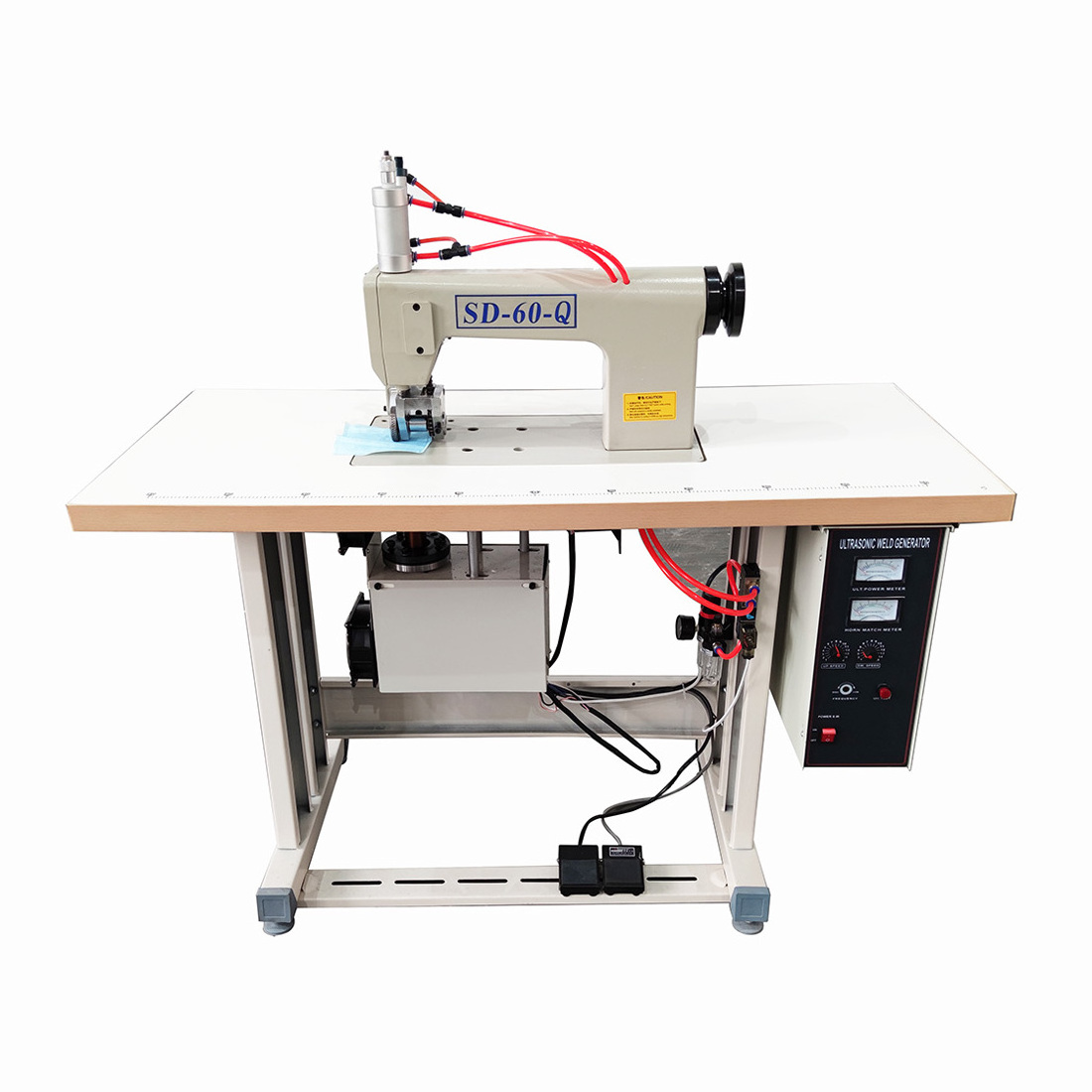

Product Paramenters

|

Source power

|

220V±5V or 110V avaliable

|

|

|

|

||

|

ULT. power

|

1800-2500W

|

|

|

|

||

|

Output frequency

|

20KHZ

|

|

|

|

||

|

Working speed

|

0-20m/min

|

|

|

|

||

|

Roller size

|

Width: 0-60mm; Diameter: Ø50mm

|

|

|

|

||

|

Dimension(L*W*H)

|

1200*600*1200mm

|

|

|

|

||

|

Net weight

|

80KG

|

|

|

|

||

Characteristics

1. Built-in PC chips, multi-circuit ultrasonic protection system to make the machine run safely;

2. Strong ultrasonic power with three adjustable gears (maximum, medium and minimum), meets the welding requirements of different

materials and thicknesses;

3. The performance of the machine reaches international level with automatic frequency tracking system and ultrasonic

soft-starting technology;

4. Variety of roller patterns, other roller designs available according to customer requirements;

5. Four times faster than sewing machines, minimal operator training required.

2. Strong ultrasonic power with three adjustable gears (maximum, medium and minimum), meets the welding requirements of different

materials and thicknesses;

3. The performance of the machine reaches international level with automatic frequency tracking system and ultrasonic

soft-starting technology;

4. Variety of roller patterns, other roller designs available according to customer requirements;

5. Four times faster than sewing machines, minimal operator training required.

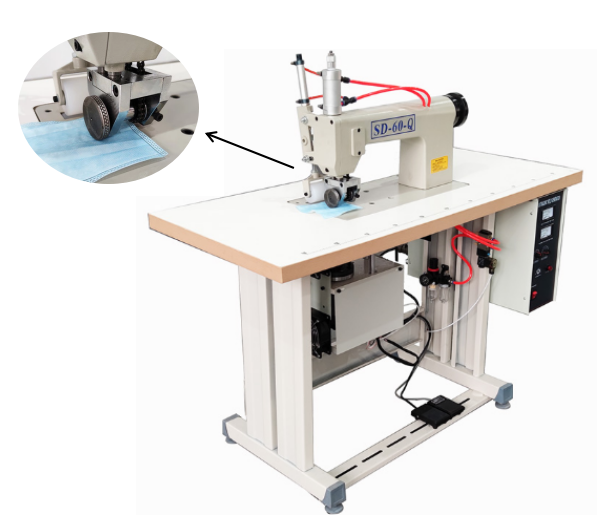

Functions

1. Trimming: Straight or curvilinear edge cutting and edge treatment for melting, so smooth, no rough edges;

2. Sealing: Two or more layers of fabric stitched together without thread replacing the sewing needles, good welding strength;

3. Hole making: Cut out the various patterns of holes, and treatment of side melting;

4. Slitting: Single or more cutting of the material at the same time, and treatment of side melting without burr;

5. Forming: Simultaneous cutting, sealing and embossing to make production in one time.

2. Sealing: Two or more layers of fabric stitched together without thread replacing the sewing needles, good welding strength;

3. Hole making: Cut out the various patterns of holes, and treatment of side melting;

4. Slitting: Single or more cutting of the material at the same time, and treatment of side melting without burr;

5. Forming: Simultaneous cutting, sealing and embossing to make production in one time.

Application

Apply to lace clothing, ribbon, decoration products, handkerchief, tablecloth, curtain, bedspread, pillowcase, quilt cover, tent, raincoat, disposable operating coat and hat, disposable mask, non-woven fabric cloth and so on.

Hot Searches