- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V/50HZ/60HZ, 220V 50hz/110V/60hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SAMMI

-

Dimension(L*W*H):

-

40*38*20MM

-

Weight:

-

7.5 KG

-

Material:

-

stainless steel

-

Name:

-

Digital Control Liquid Filling Machine

-

Model:

-

GFK-160

-

Filling range:

-

3-3000ml

-

Filling speed:

-

max 3.2L/min

-

Local Service Location:

-

None

-

Marketing Type:

-

New Product 2020

Quick Details

-

Machinery Capacity:

-

500BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V/50HZ/60HZ, 220V 50hz/110V/60hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SAMMI

-

Dimension(L*W*H):

-

40*38*20MM

-

Weight:

-

7.5 KG

-

Material:

-

stainless steel

-

Name:

-

Digital Control Liquid Filling Machine

-

Model:

-

GFK-160

-

Filling range:

-

3-3000ml

-

Filling speed:

-

max 3.2L/min

-

Local Service Location:

-

None

-

Marketing Type:

-

New Product 2020

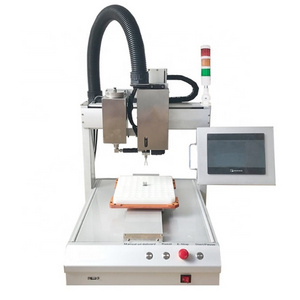

Compact Digital Control Pump Liquid Filling Machine

Controled by micro-computer, fill liquid by setting the filling time and speed.

Filling Liquid From 3-3000ml very precisely.

Digital Panel, very easy to operate.

Technical Parameter:

Voltage: AC 180V-260V

Power: 30W

Filling Range: 3ml-3000ml

Max Flow Rate: 3.2L/min

Package Size: 400X380X200 (mm)

Weight: 5.5kgs

Max Suck Distance: 2meter

Anti-dripping Funtion: Available

Memory Function out of power: Available

Interior diameter of filling nozzle: 5mm (if you need smaller 3mm, please let us know.)

Characteristics:

1. Import single-chip microcomputer control, high efficiency, low power consumption

2. Automatic counting function, effectively control filling quantiy

3. LCD display, touch screen is very easy to operate

4. High filing accuracy

5. Wide Voltage range

6. Working performance is stable and can be used for long time

7. This can self-suck the liquid.

8. The pump can stand acid and alkali

9. Anti-dripping design.

10. Reasonable design, made of stainless steel, meet GMP requirement

Application:

suitable for low viscous liquid like water,oil,perfume,soft drink,milk,beverage,chemical liquid etc.

Not suitable for

very thick liquid ( like sauce, shampoo, detergent etc), or liquid containing small particles.

Note:the machine use silicone tube to suck liquid. If fill different liquid, it can suck water to clean the pump or it can change another tube to fill.

Installation and operation:

Take the small filter out of the part.and install it below the feeding tube,Take the plastic filling Nozzle out and install it in the feeding tube(Notice the triangel head connects the discharge tube),Take out the filling-heat stand and install it on the left of the machine as shows, put the filling head in the clip and tighten it by socket wrench,Connect the pedal switch with machine,and put the tube with filter below the liquid level inside the storeage tank, the position of tank should be lower than the machine,start to test the machine after all is ready.

Machine pictures: