- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support

-

Name:

-

cookware utensil bottom induction brazing welding machine

-

Color:

-

Blue

-

Application:

-

BRAZING

-

Usage:

-

cookware induction

-

Voltage:

-

380V

-

Power:

-

50KW

-

Model:

-

STYL-60

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YUELON

-

Core Components:

-

circuit board

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support

-

Name:

-

cookware utensil bottom induction brazing welding machine

-

Color:

-

Blue

-

Application:

-

BRAZING

-

Usage:

-

cookware induction

-

Voltage:

-

380V

-

Power:

-

50KW

-

Model:

-

STYL-60

-

Certification:

-

CE ISO

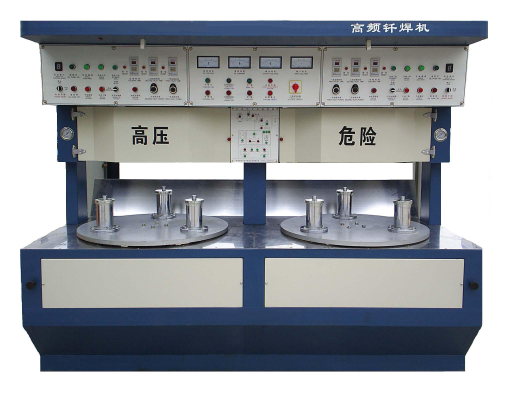

Cookware composite pot bottom brazing machine / cookware sandwich bottom brazing machine for pan, pot, kettle

Cookware pan bottom induction brazing machine is mainly used for cookware compound bottom welding of stainless steel pan, pot, kettle, and also can be used for plane heating of other workpiece. Cookware Pan and pot bottom brazing machine is an mechanical, hydraulic and electrical integrated equipment controlled by several sets microcomputer. The main performance index takes the leading position at home and aboard.

According to the difference of heating power supply and welding diameters, this cookware sandwich bottom induction brazing equipment can be divided into a variety of models, such as:

A. Transistor high frequency cookware bottom brazing machine

Features:

1.Using high power transistor, safety and reliability, energy saving.

2.Uniform heating and good welding quality.

3.Fast heating speed and high production rate.

4.Digital display of operating mode, simple operation and easy maintenance.

Power: 50KW, 80KW, 100KW

Frequency: 200-300KHz

Welding diameter: 100-500mm

B. Vacuum tube high frequency brazing machine

Features:

1.Using traditional vacuum tube, the technology is mature and reliable.

2.Fast heating speed and high production efficiency.

3.The overall design is reasonable, small heat loss, and beautiful appearance.

4.Internal pressurizer, low price and small investment.

5.Digital display of operating mode and easy maintenance

Power: 60KW, 100KW, 150KW

Frequency: 200-300KHz

Welding diameter: 100-500mm

Main models and specifications:

|

Model |

Power supply |

description |

Rated power |

Max welding diameter |

Size L x W x H mm |

|

V-21-60kw/280 |

Vacuum tube |

Single heating head double station |

60KW |

280mm |

2450 x 3100 x 2000mm |

|

V-21-100kw/240 |

Vacuum tube |

Double heating head double station |

100KW |

380mm |

2650 x 3100 x 2000mm |

|

V-21-150kw/500 |

Vacuum tube |

Single heating head double station |

150KW |

500mm |

2850 x 3100 x 2000mm |

|

T-11-50kw/280 |

Transistor |

Single heating head single station |

50KW |

280mm |

1350 x 3100 x 2000mm |

|

T-21-50kw/280 |

Transistor |

Single heating head double station |

50KW |

280mm |

2450 x 3100 x 2000mm |

|

T-21-80kw/340 |

Transistor |

Single heating head double station |

80KW |

340mm |

2650 x 3100 x 2000mm |

|

T-21-100kw/360 |

Transistor |

Single heating head double station |

100KW |

380mm |

2650 x 3100 x 2000mm |

Q:Why can I trust your company and choose you?

A: We are a professional induction heating equipment and set r & d, production, sales, service as one of the high-tech enterprises.We have 22 years of professional experience in production and equipment research and development, is currently China's most professional brazing machine, heating complete automation equipment manufacturers.

Q:Where is your company, may I come to visit?

A:Yes,our company located in NO.25 Jinshan East Road,Wujin Technology Park,Yongknag,Jinhua,Zhejiang,China. And you will be welcome to visit our factory at any time

Q:How to install your machine

A:We have paper installation instructions and video, we will teach till you learn it.

Q:Do you have any equipment in stock?

A:Yes, we have some of the best-selling models in stock, and can shipped immediately after payment

Q: Can you provide free samples of the machines?

A: Sorry, but we can't give you free samples because of the high price of the machines. Our machines will certainly meet your requirements and satisfy you

Q:How is your quality control?

A:We have a professional team responsible for product testing and packaging before delivery, you can be assured to purchase.

Q:How many days can the machine arrive after I bought it?

A:Usually 5-10 days(excluding holiday),large machines take 20-30 days

Q: If the machine get damaged, what can I do ?

A: We will give you some spare parts free of charge during the one-year shelf life of the machine.For the customers who have bought the machine, if there is any problem with the machine, they can take a photo or record a video to us. We will guide the customers to perform the repair.If we still cannot solve the problem, we can send our engineers to your factory.

Q.How about the warranty?

A: All our products have one year quality warranty, during the warranty time, the spare parts replacement is free. And we provide life long time technical support and other assistance.